Twin wire gap former paper making machine with variable wrap impringement shoe

A paper machine and forming shoe technology, applied in the field of scraper-type double-fabric forming section, can solve the problems of bulkiness, difficult slurry jet guidance, inaccurate and cumbersome fine-tuning control of weir lips, etc., and achieve the effect of keeping the track unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

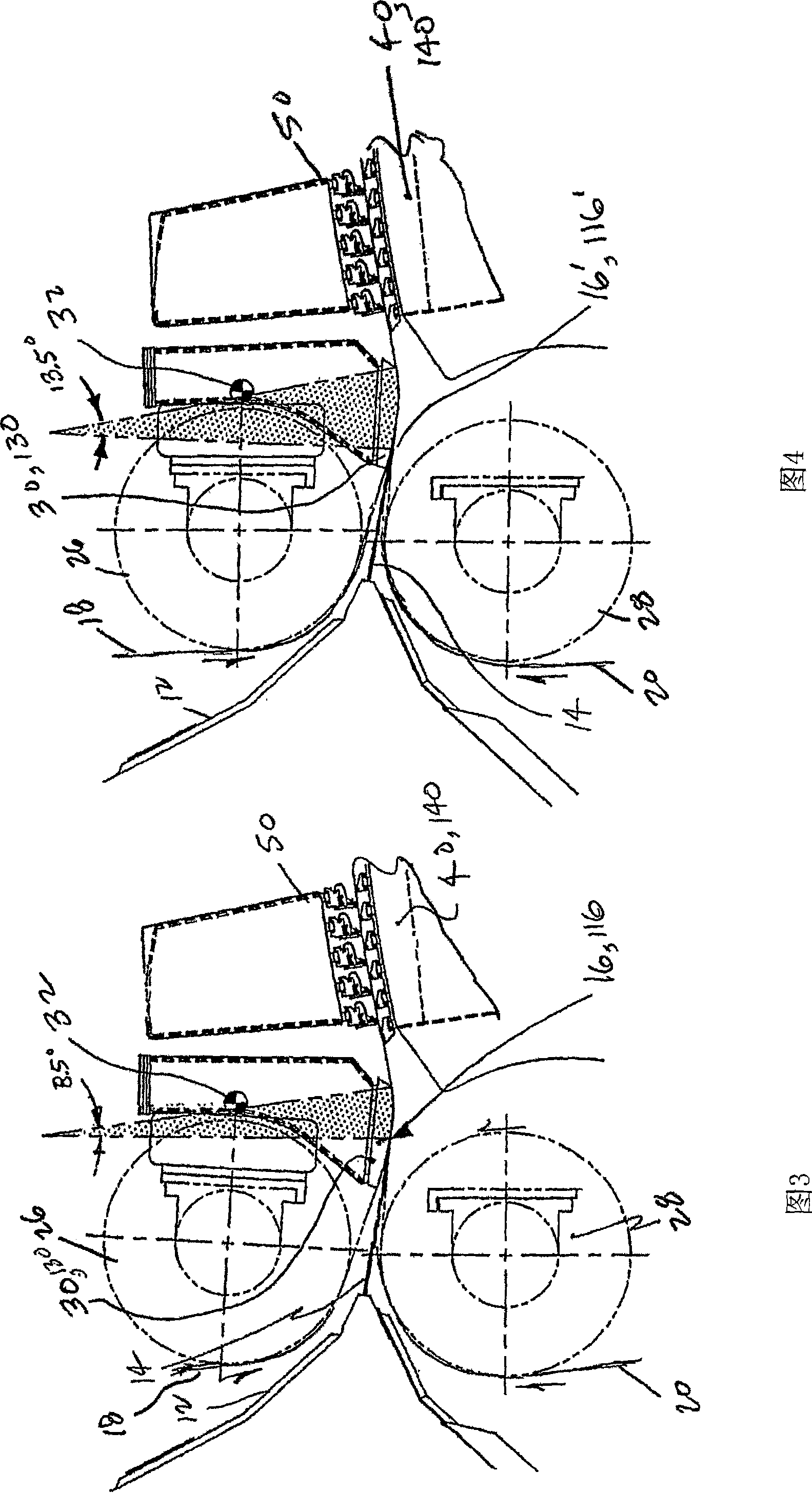

[0039] Certain terminology is used below for convenience only and should not be considered limiting. The words "lower", "upper", "left" and "right" indicate directions in the drawings to which reference is made. The terms "a" and "one" are defined to include one or more of the referenced parts unless expressly stated otherwise. The term "effective wrap angle" refers to the wrap angle from the point of impact of the jet to the trailing edge of the impact shoe. The term "fabric offset angle" refers to the angle formed by the forming fabric at the impact shoe trailing edge and / or the forming shoe leading edge.

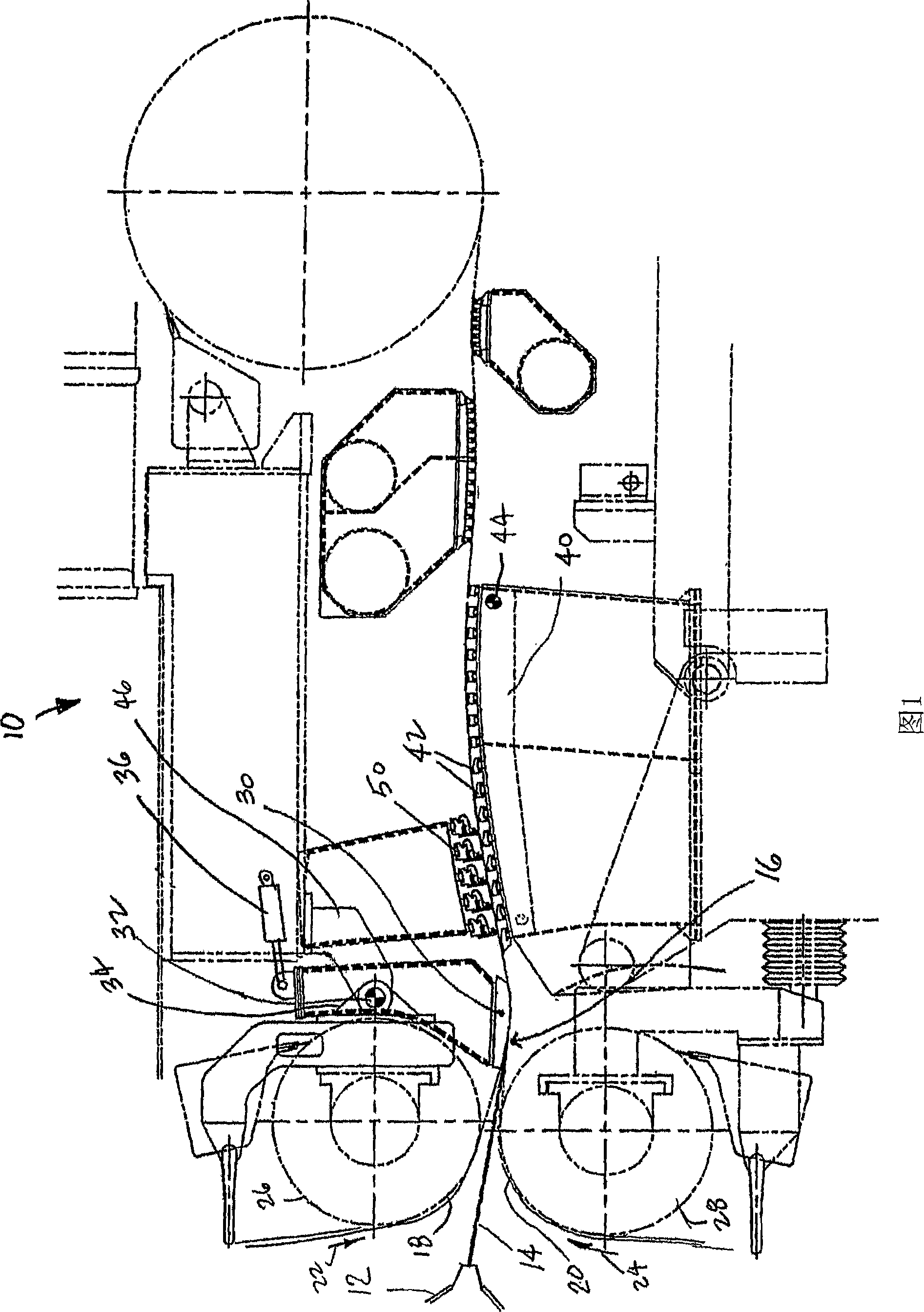

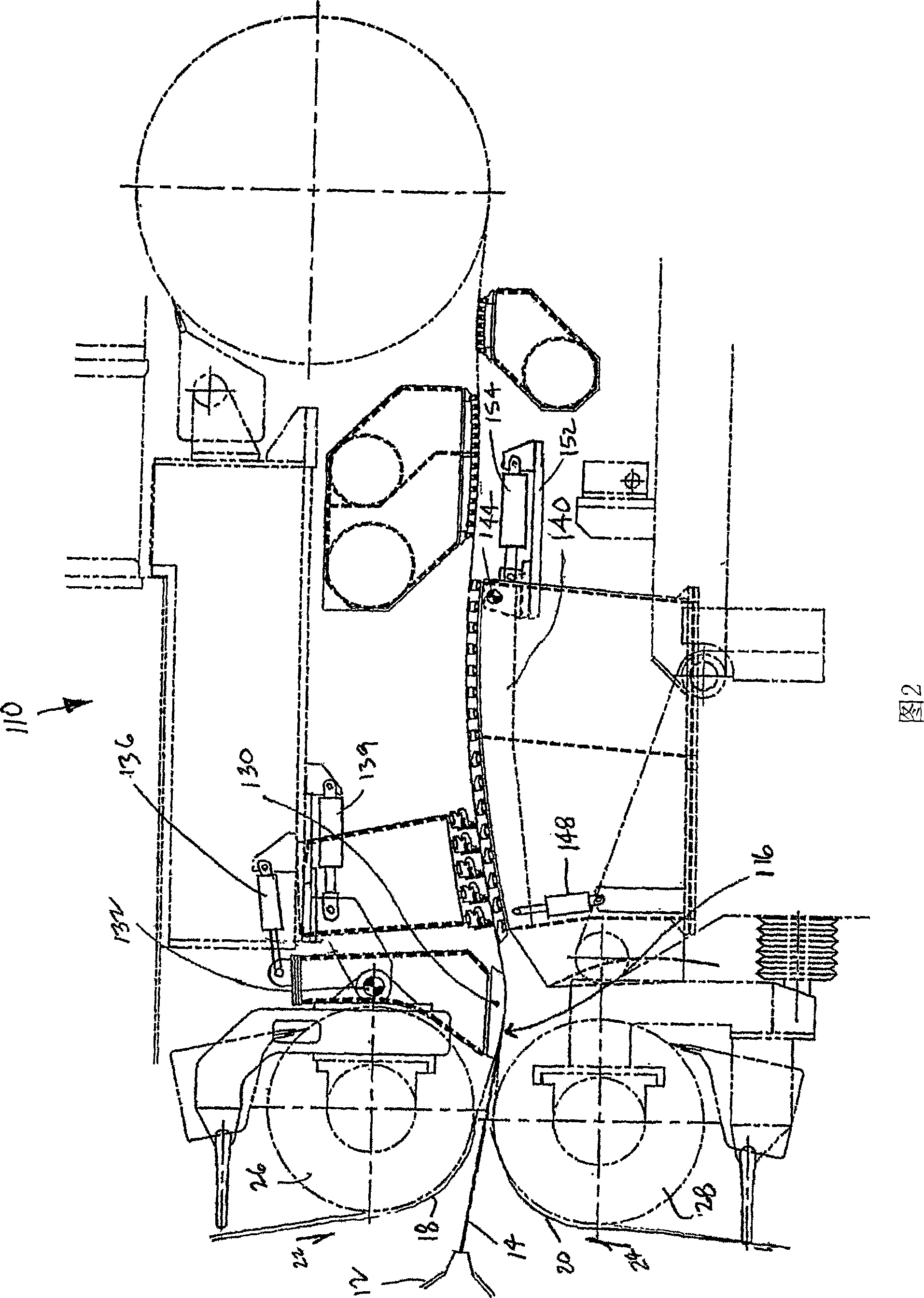

[0040] see now figure 1 , which shows the forming section 10 of a doctor blade forming paper machine. The forming section 10 includes a headbox 12 which delivers a stream of papermaking slurry 14 to a point of impact 16 on a conveying forming fabric 18 . A support forming fabric 20 is also provided which joins the delivery forming fabric 18 at or very close to the poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com