Rapid preparation method and application of colloidal probe

A technology of probes and colloids, which is applied in the field of rapid preparation of colloidal probes, can solve problems such as unfavorable universal use, limited application range, and easy to pollute the surface of samples, so as to reduce the probability of pollution or damage, expand the scope of application and research, The effect of improving the success rate of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Substrate material cleaning. Place a piece of 18*18*2mm glass piece in ultrapure water, acetone, and ultrapure water in sequence, ultrasonically clean it for 10 minutes respectively to fully remove surface pollutants, and then dry it for later use to obtain glass piece G.

[0059] 2. Colloid solution dilution. Set the concentration to 4.99 x 10 8 particles / ml, the stock solution A of polystyrene beads with a particle size of 4.5um was diluted with ultrapure water to obtain a concentration of 2.50×10 6 particles / ml of dispersion B.

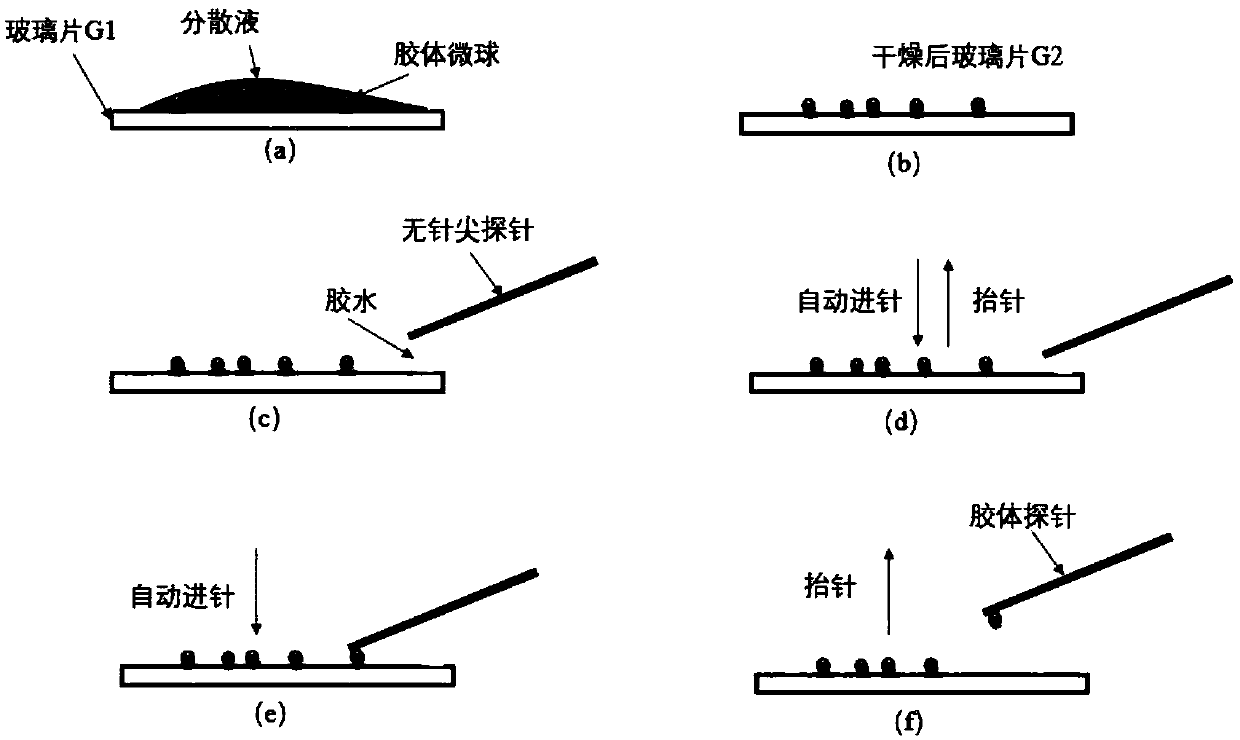

[0060] 3. Dispersion of colloidal spheres. Use a pipette to take 20uL of dispersion B and drop it on one side of the cleaned glass slide G1, such as figure 1 Shown in (a).

[0061] 4. The dispersion is dried. On the heating plate, under the condition of 40°C, properly heat the glass sheet to accelerate the volatilization of the dispersion liquid, dry the microspheres, and obtain the glass sheet G2 uniformly covered with microspheres...

Embodiment 2

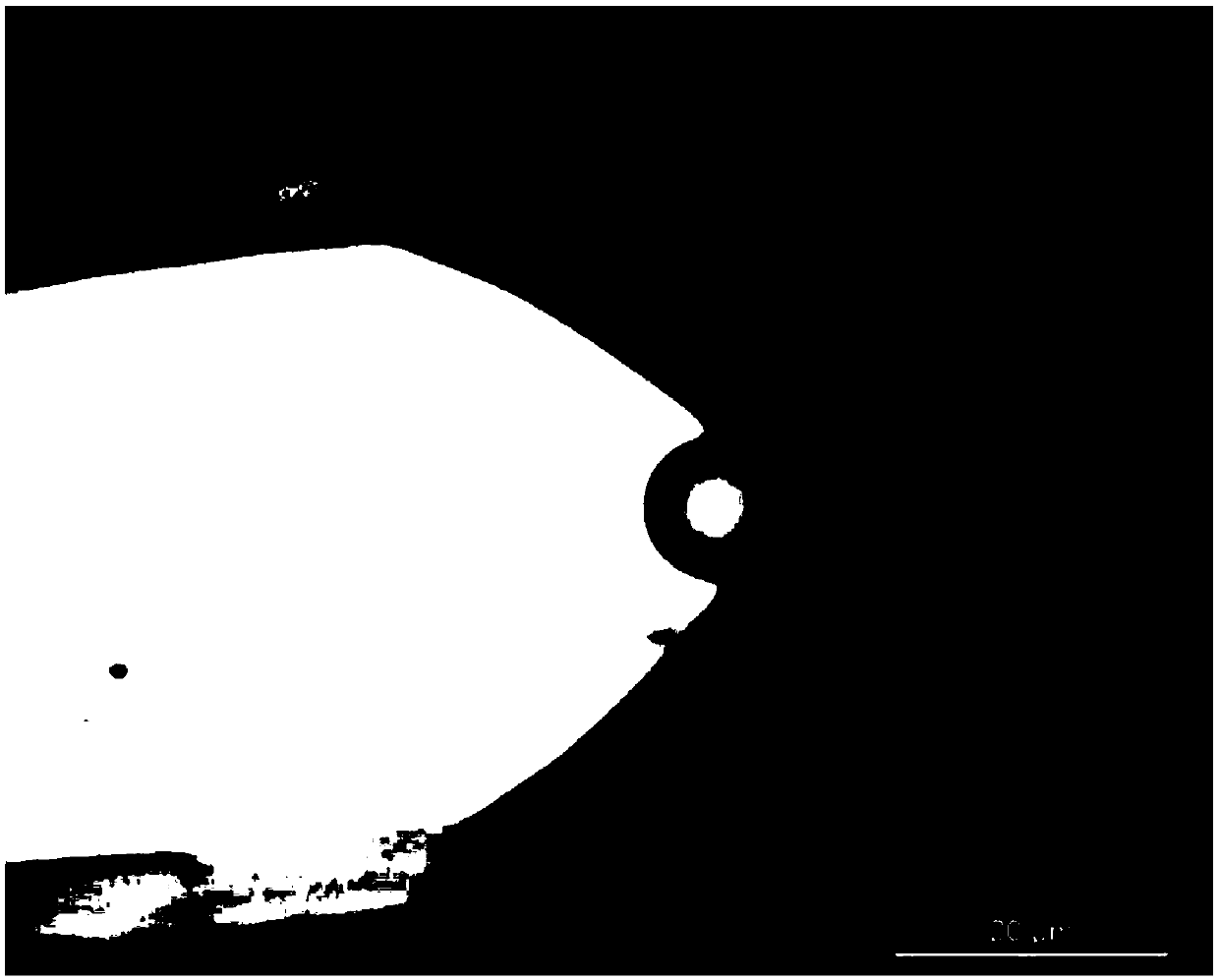

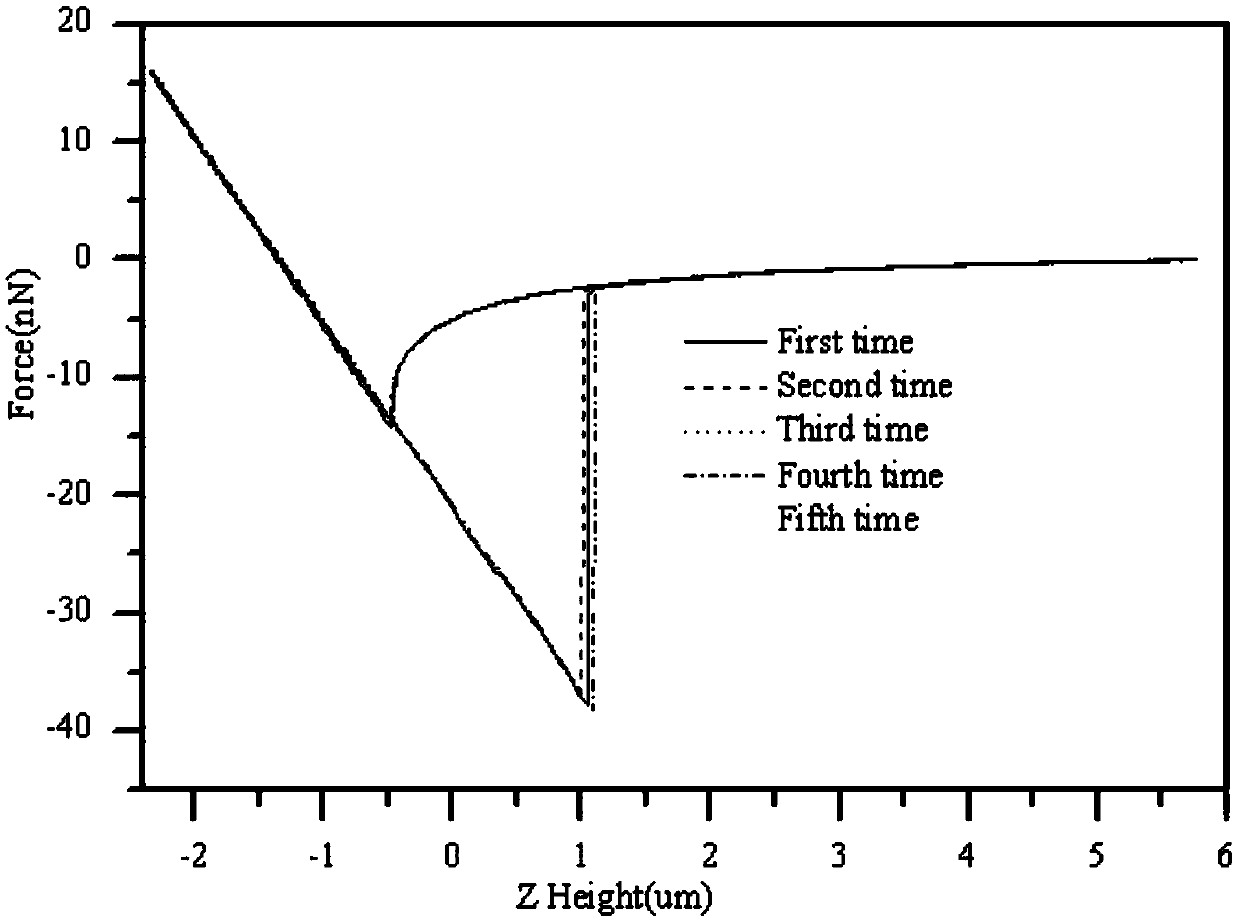

[0069] According to the TL-COUNT probe prepared in Example 1, the non-contact force between the colloidal microsphere and the glass plate was studied, and the F-D curve was tested by using the Contact mode of ParkNX10AFM. The specific steps are as follows:

[0070] 1. AFM parameter calibration. Install the newly prepared colloidal probe, and adjust the AFM calibration probe parameters, including "Sensitivity", "Force slope" and "Force constant". After calibration, the "Sensitivity" and "Force constant" are 4.1V / um and 10 -3 (N / m).

[0071] 2. Test base preparation. A 15*15mm clean glass sheet with a roughness less than 100nm was selected as the base, the needle feeding / lifting speed was set to 1.0um / s, and the experiment was carried out at room temperature. For the detailed experimental process, please refer to [Assemi S, Nalaskowski J, Johnson W P. Direct force measurements between carboxylate-modified latexmicrospheres and glass using atomic force microscopy[J].Colloids a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com