Device and method for measuring overall bulk modulus of cells based on ultrasonic standing wave sound field

A technology of ultrasonic standing wave and elastic modulus, which is applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Direct measurement of suspended cells, unable to reflect the elastic modulus of cells, etc., to avoid inaccurate measurement, avoid large local deformation, and continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

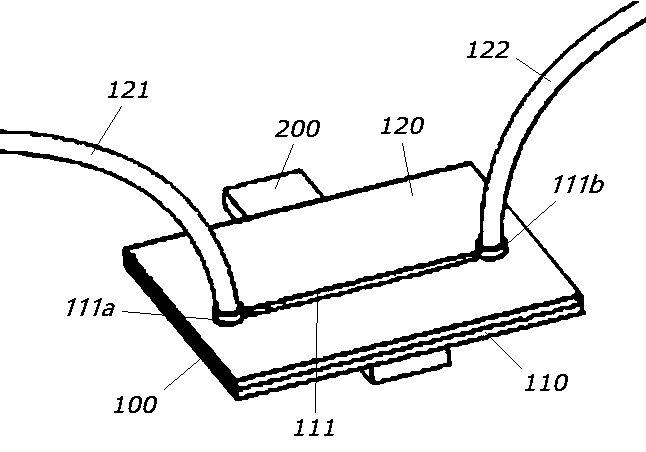

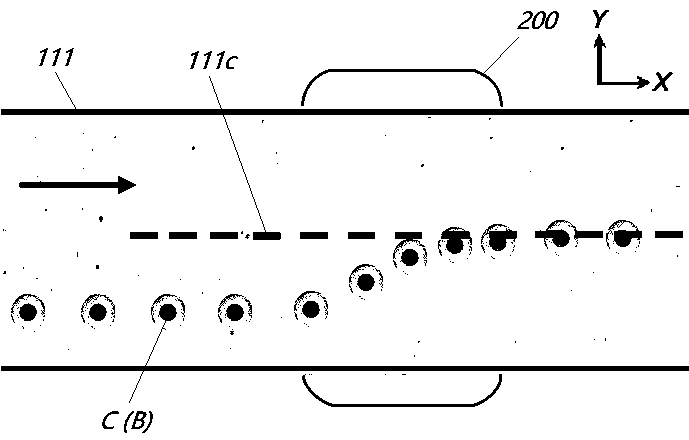

[0048] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the core part of the embodiment of the device for measuring the overall elastic modulus of cells based on the ultrasonic standing wave sound field in the present invention. The core part of the measurement device is composed of a micro-channel chip 100 and a piezoelectric ceramic 200; the micro-channel chip 100 A microfluidic channel 111 is arranged on the top, the piezoelectric ceramic 200 is in contact with the bottom surface of the microfluidic chip 100, and the piezoelectric ceramic 200 is located below the microfluidic channel 111, and is used to generate The ultrasonic standi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com