Method for disassembling micro-electro-mechanical devices under assistance of laser impact

A technology of laser shock and electrical devices, which is applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of difficult disassembly, scratch damage of devices, etc., and achieve the effect of avoiding contact scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

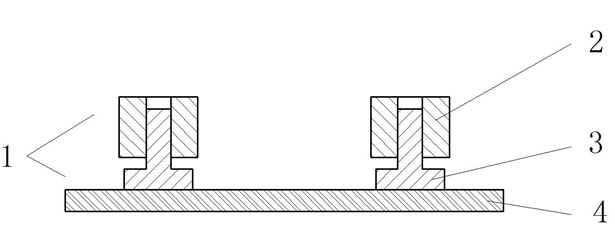

[0035] The MEMS device I2 is attached to the MEMS carrier wafer 4 , and the MEMS device II3 is interference-connected with the MEMS device I2 to form the MEMS 1 .

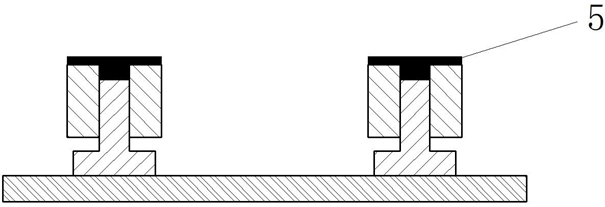

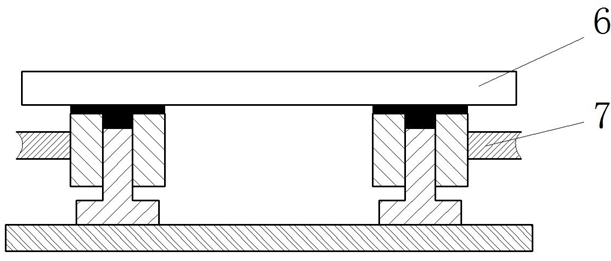

[0036] Wash the surface of the MEMS device I2 and the MEMS device II3 with alcohol or acetone, pre-coat the absorbing layer 5 on the back of the MEMS device I2 and the MEMS device II3, the thickness of the absorbing layer 5 is 0.1-0.15 mm, and there is enough viscosity to make The MEMS 1 will not fall off from the surface of the metallic glass 6; the MEMS 1 is adhered to the surface of the high-strength metallic glass 6 by using the viscosity of the absorbing layer 5, and the metallic glass 6 serves as the carrier for the MEMS 1 and the constraints of the laser shock layer; the metallic glass 6 carrying the micro-electro-mechanical syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com