High-temperature oxygen-controlled magnetic drive liquid metal rotating corrosion experimental device and method

A liquid metal, magnetic drive technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of hidden leakage, high liquid metal driving power, complicated pipeline circuits, etc., to achieve low failure rate, improve Reliability and work efficiency, the effect of compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

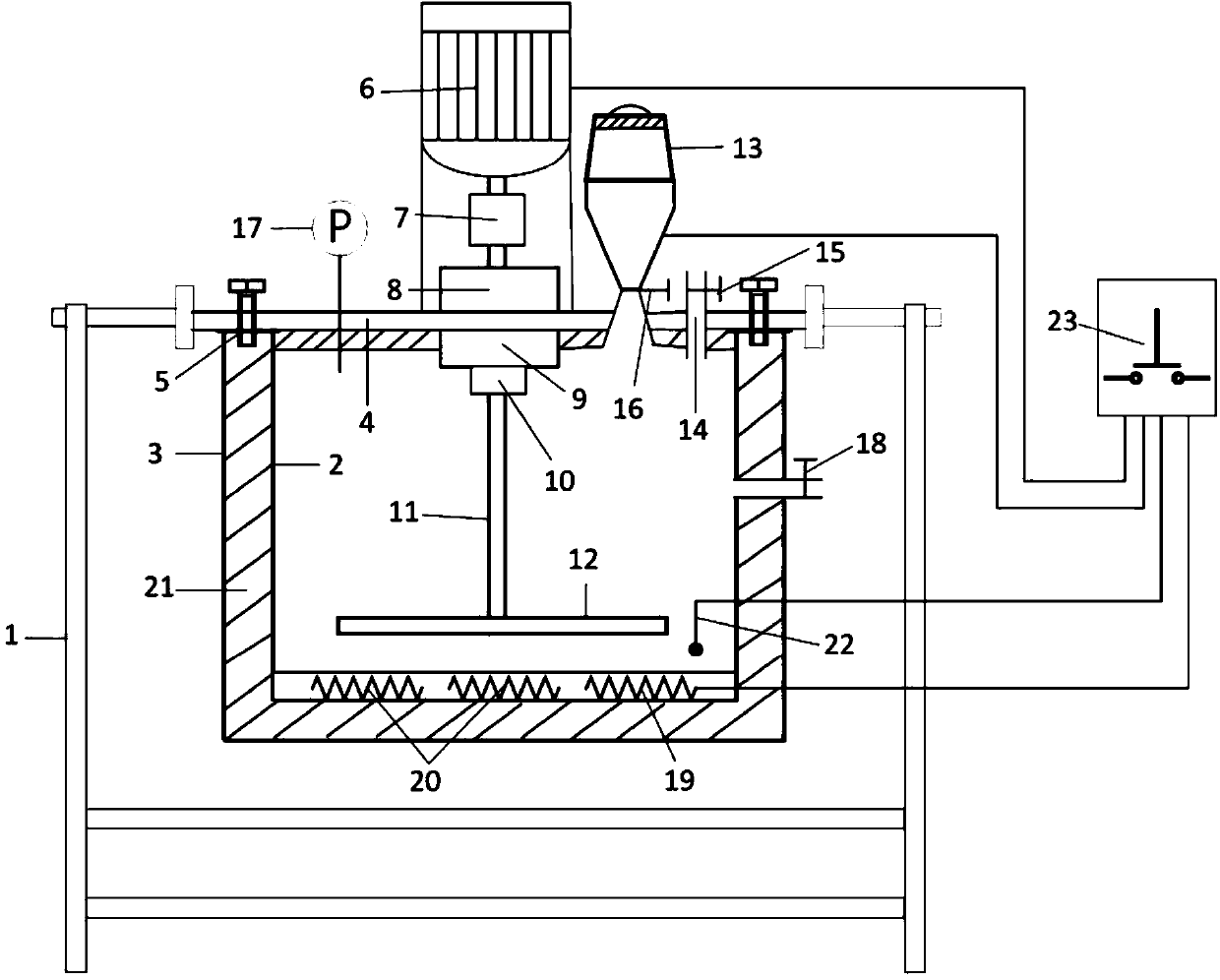

[0032] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0033] The specific embodiment of the invention is to adopt the attached figure 1 The schematic diagram of a high-temperature oxygen-controlled magnetic force-driven liquid metal rotary corrosion experimental device is shown.

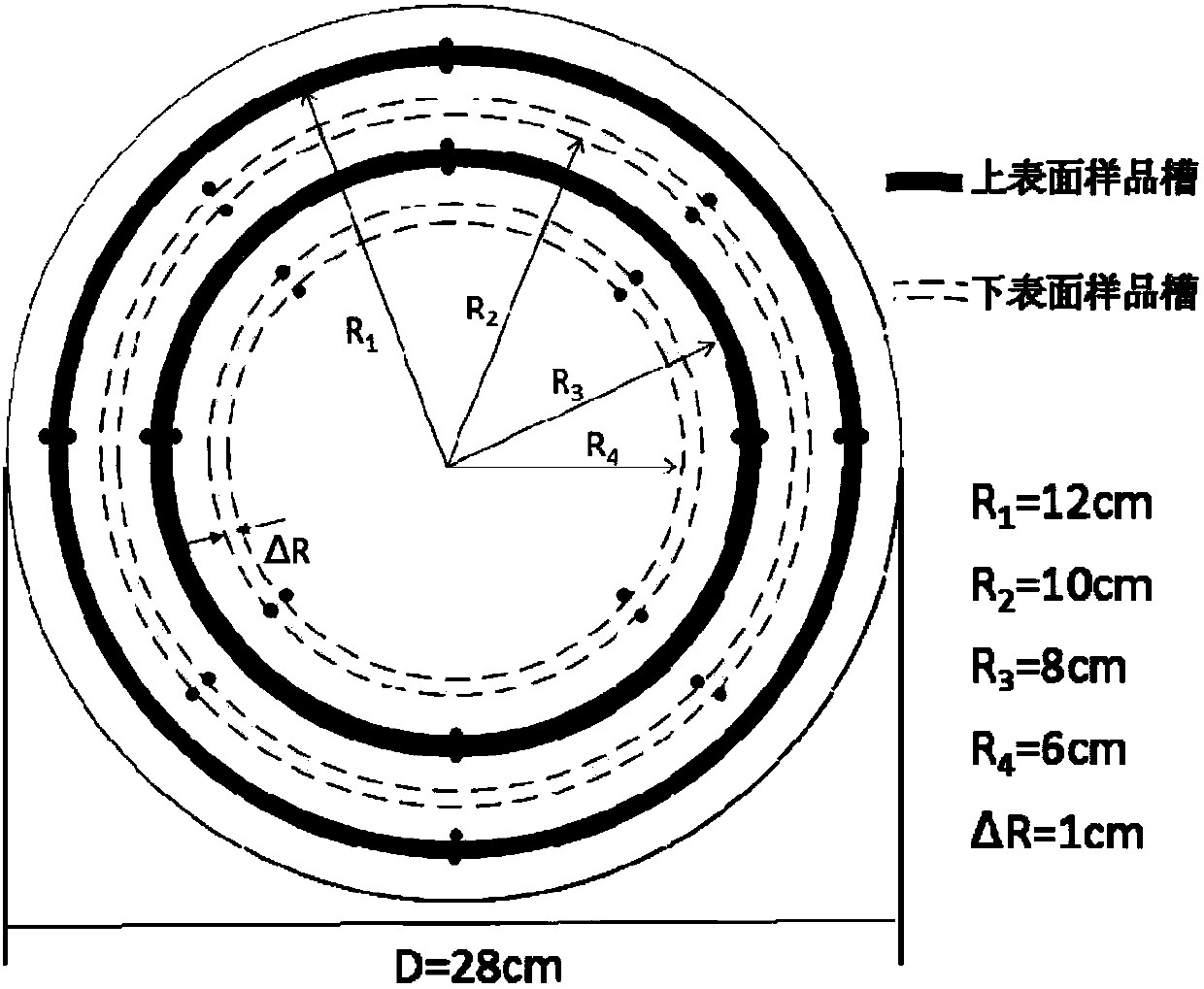

[0034] The invention adopts a high-temperature oxygen-controlled magnetic force driven liquid metal rotary corrosion experiment device, which consists of a reversible support frame 1, an inner tank body 2, an outer tank body 3, a tank cover 4, a sealing assembly 5, a motor 6, and a reducer 7 , outer magnetic rotor 8, inner magnetic rotor 9, clamp coupling 10, transmission shaft 11, disc-shaped sample holder 12, melting tank 13, air inlet and outlet 14, air inlet needle valve 15, feed inlet gate valve 16, It consists of pressure gauge 17, pressure reducing valve 18, main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com