A Calculation Method of Load Distribution Between Teeth with Edge Contact

An edge contact and load distribution technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as small computational complexity, insufficient perfection and accuracy, and unreliable solution results, reducing computer time and solving computationally complex problems. problems, the simple effect of gear force analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

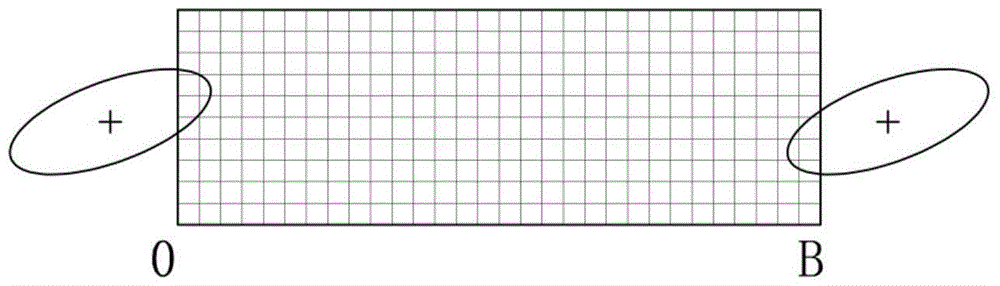

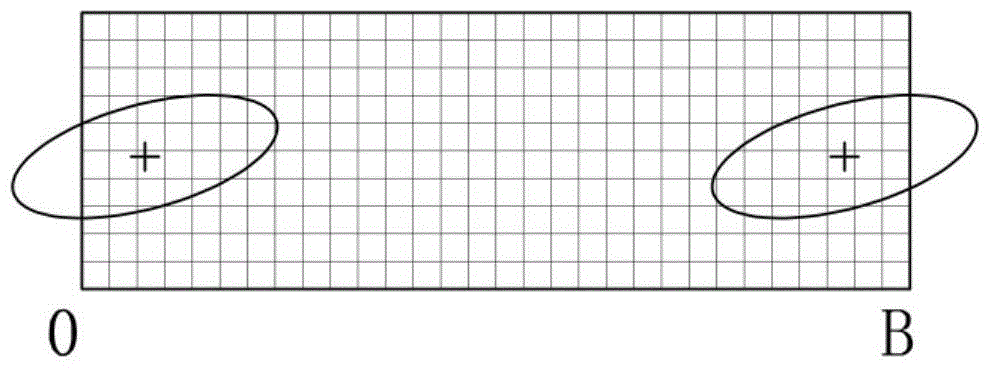

[0053] (1) Carry out contact analysis of gear loading without considering edge contact

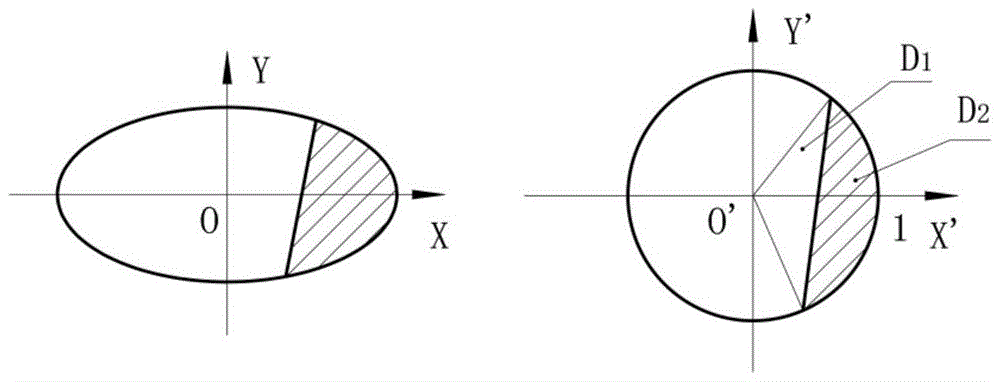

[0054] Through tooth surface contact analysis (TCA), it can be obtained that the tooth surface contact situation of each large and small gear pair at the moment of no load is applied, that is, the contact position of the tooth surface participating in the meshing, static transmission error, main curvature of the contact point position, The main direction and the curvature of the induced method can establish the relationship between the size of the contact ellipse, the compression amount of the tooth surface and the load at each contact position, and at the same time, the direction of the contact ellipse can also be obtained.

[0055] According to the transmission errors of multiple pairs of tooth surfaces obtained by the above-mentioned gear tooth contact analysis (TCA), it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com