A combine harvester and its cleaning screen box

A combine harvester and sieve box technology, applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems of inconvenient disassembly, time-consuming and labor-intensive, affecting operation efficiency, etc., achieve quick disassembly, improve operation efficiency, The effect of the best cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

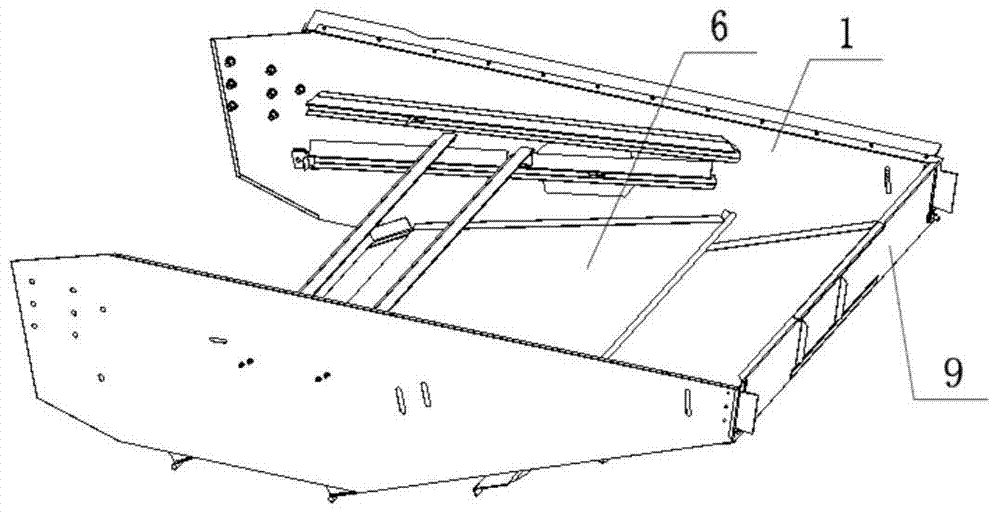

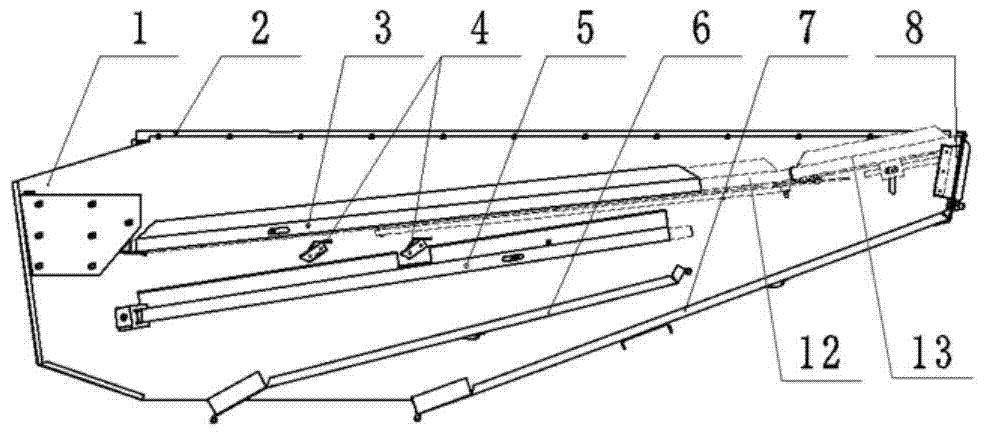

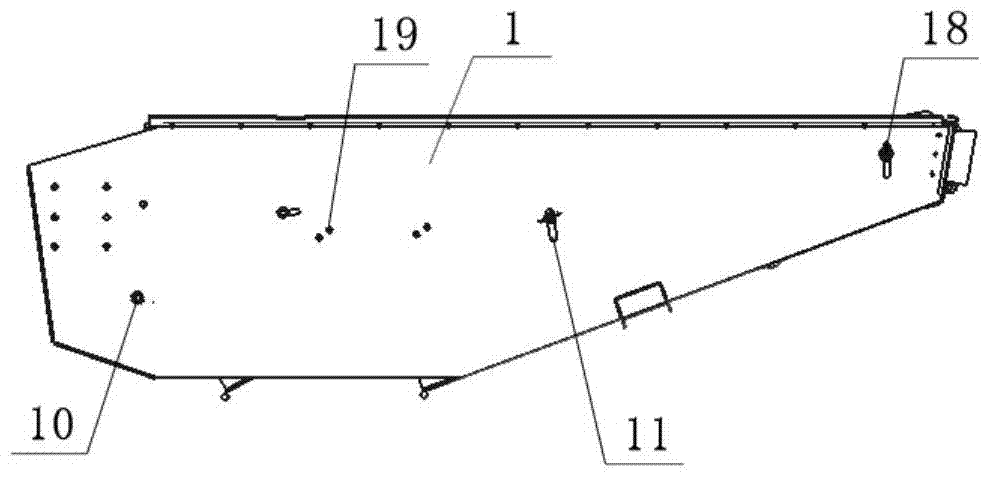

[0020] see figure 1 , figure 2 , a cleaning screen box of a combine harvester, comprising two side wall panels 1, a tailgate 9 is connected between the tail ends of the two side wall panels, and the upper Rough selection screen 12, selection screen and grain slideway 6 are arranged successively from bottom to bottom, and upper screen support chute 3 and lower screen support chute 5 are arranged on the inner sides of the two side wall panels, and the coarse selection screen is inserted in the In the support chute of the upper screen, the selection screen is inserted in the support chute of the lower screen.

[0021] In this embodiment, the cleaning screen box is assembled between the machine bodies. The two side wall panels 1 are composed of two thin sheet metal parts. The two side wall panels are connected by welding the grain slideway 6. There is a sealing strip 8 between the two side wall panels, which constitutes the framework of the cleaning screen box. The inner sides...

Embodiment 2

[0036] A combine harvester, which includes the cleaning screen box. For the technical content of the cleaning screen box, please refer to the content disclosed in Embodiment 1, and the description will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com