Metering type lead screw color master proportional valve

A proportional valve and color masterbatch technology, applied in the field of proportional valve components, can solve the problems affecting product quality, low tightness of production lines, and integration of production lines, etc., to achieve the effect of fully automated work and reliable mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described by taking a specific metering screw masterbatch proportional valve as an embodiment.

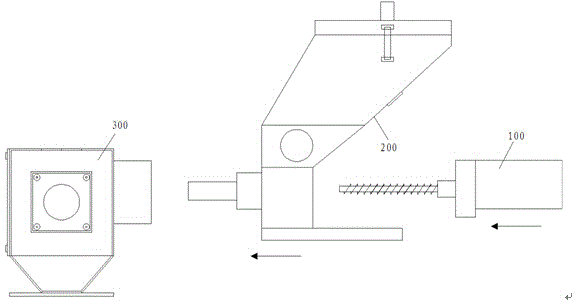

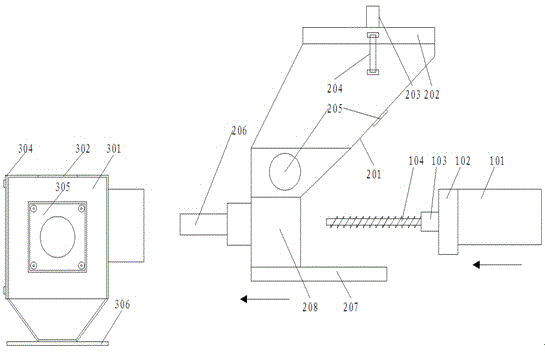

[0030] Such as figure 1 As shown, the metering screw color masterbatch proportional valve of the present invention is characterized in that: it includes a feeding assembly 100, a feeding assembly 200 and a mixing valve assembly 300, and the feeding assembly quantitatively transports the color masterbatch in the feeding assembly to In the mixing valve assembly;

[0031] Such as figure 2 As shown, the feeding assembly includes a stepping motor 101, and the stepping motor drives a feeding screw 104 to rotate and feed;

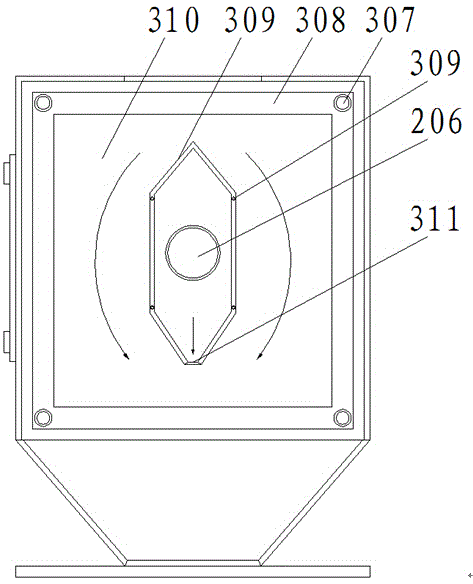

[0032] Such as figure 2 As shown, the blanking assembly includes a color masterbatch hopper 201 for storing color masterbatch, the bottom of the color masterbatch hopper is a discharge chamber 208, and the entire color masterbatch hopper is installed on a horizontal slider base 207; the discharge chamber contains Inlet and outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com