Patents

Literature

41results about How to "Fully automated work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

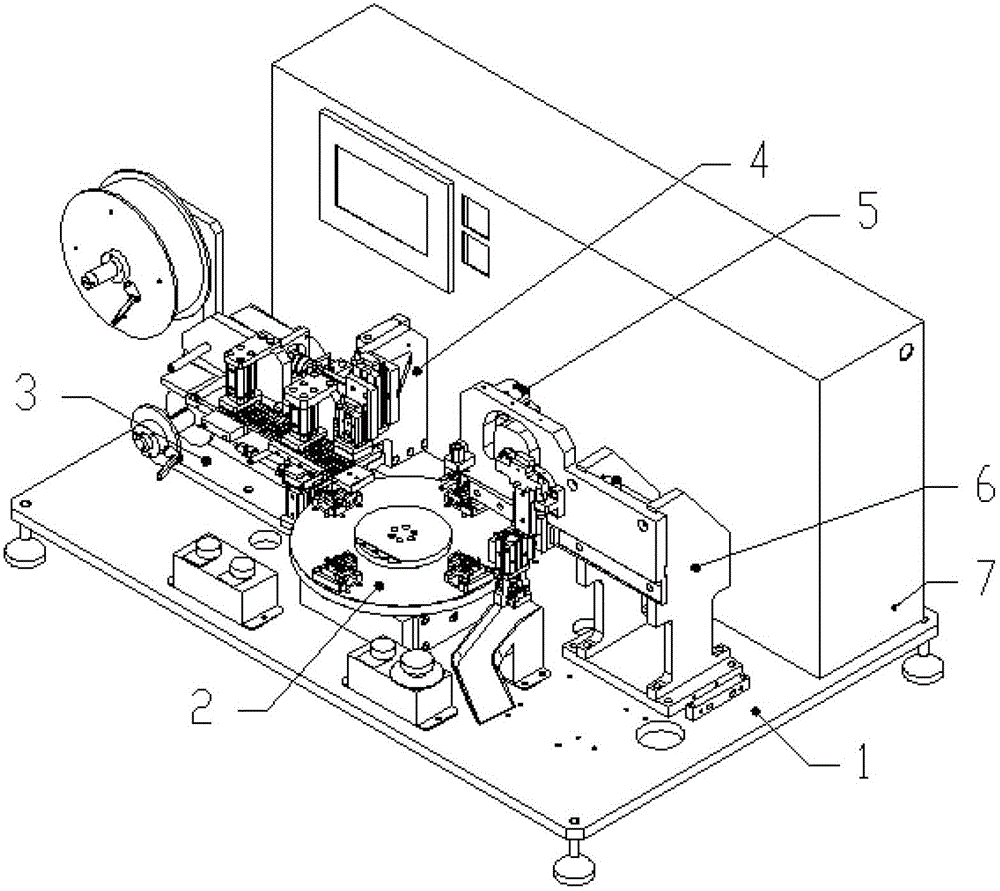

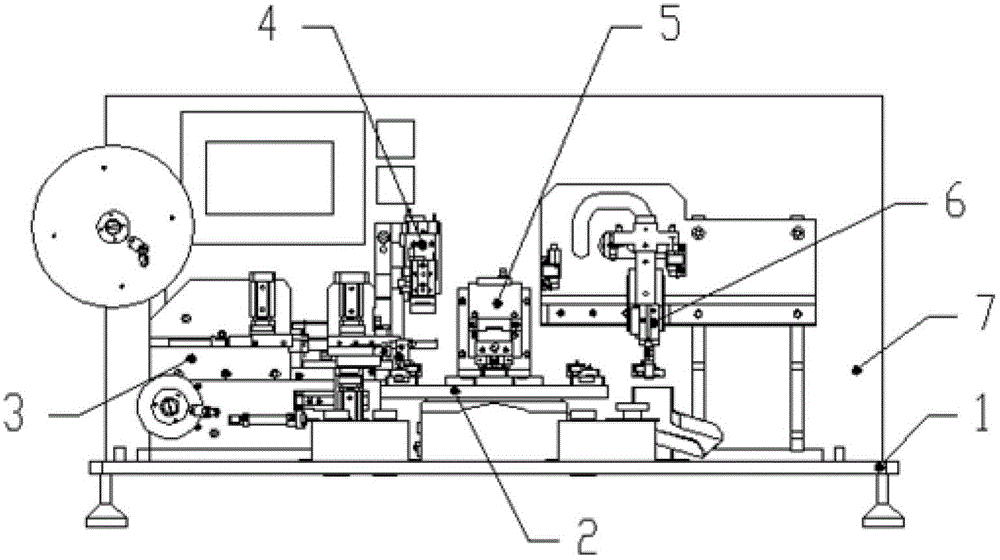

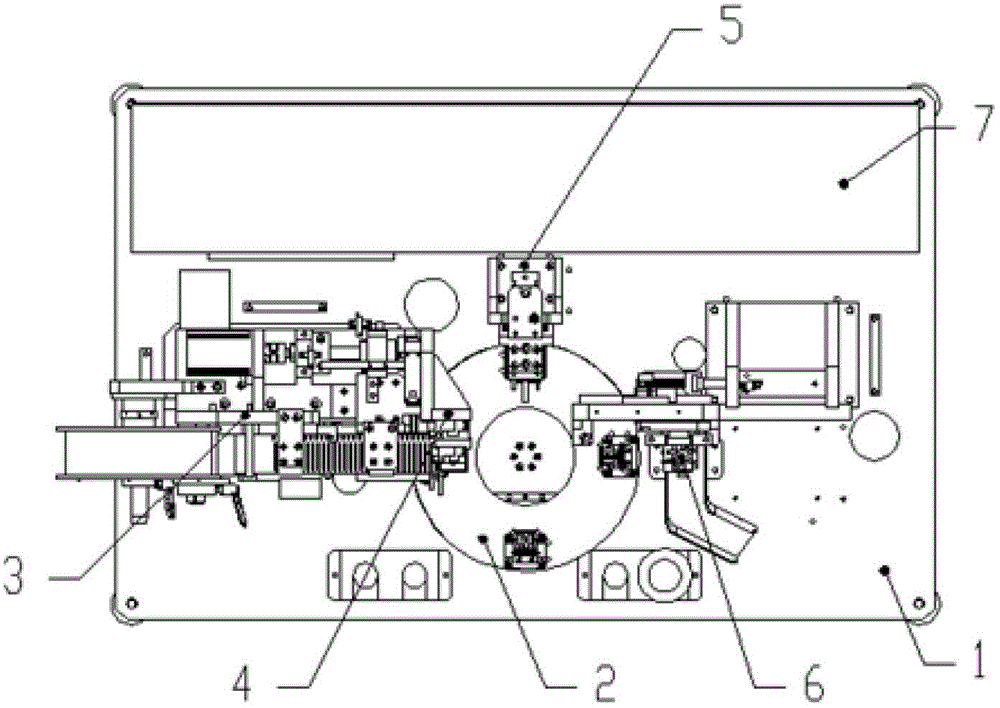

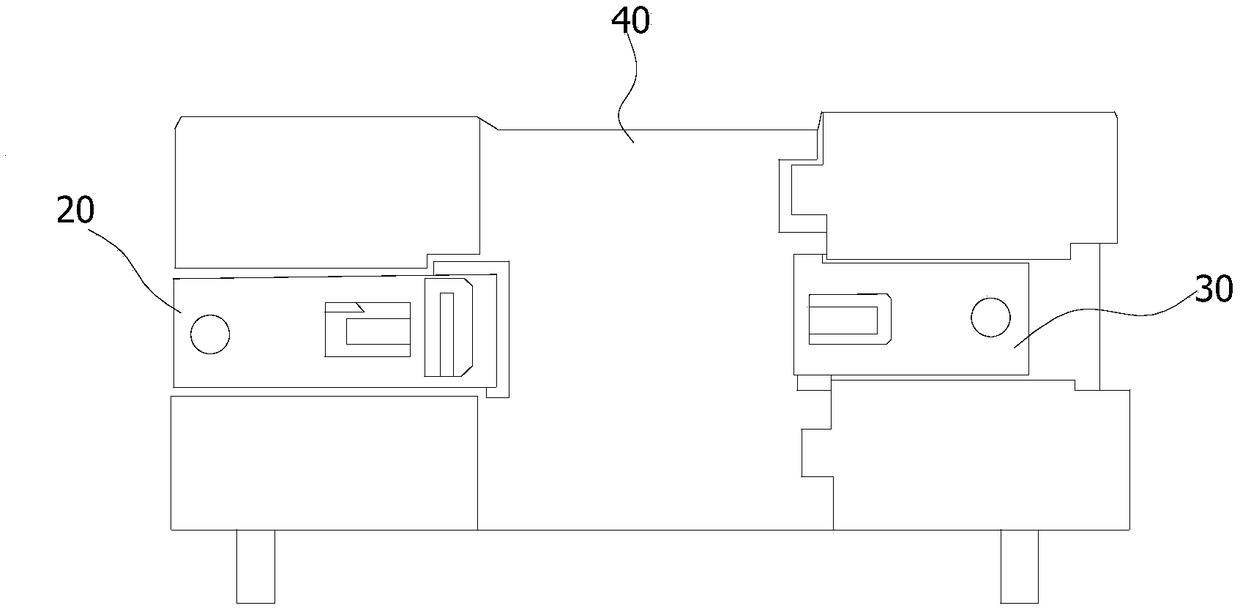

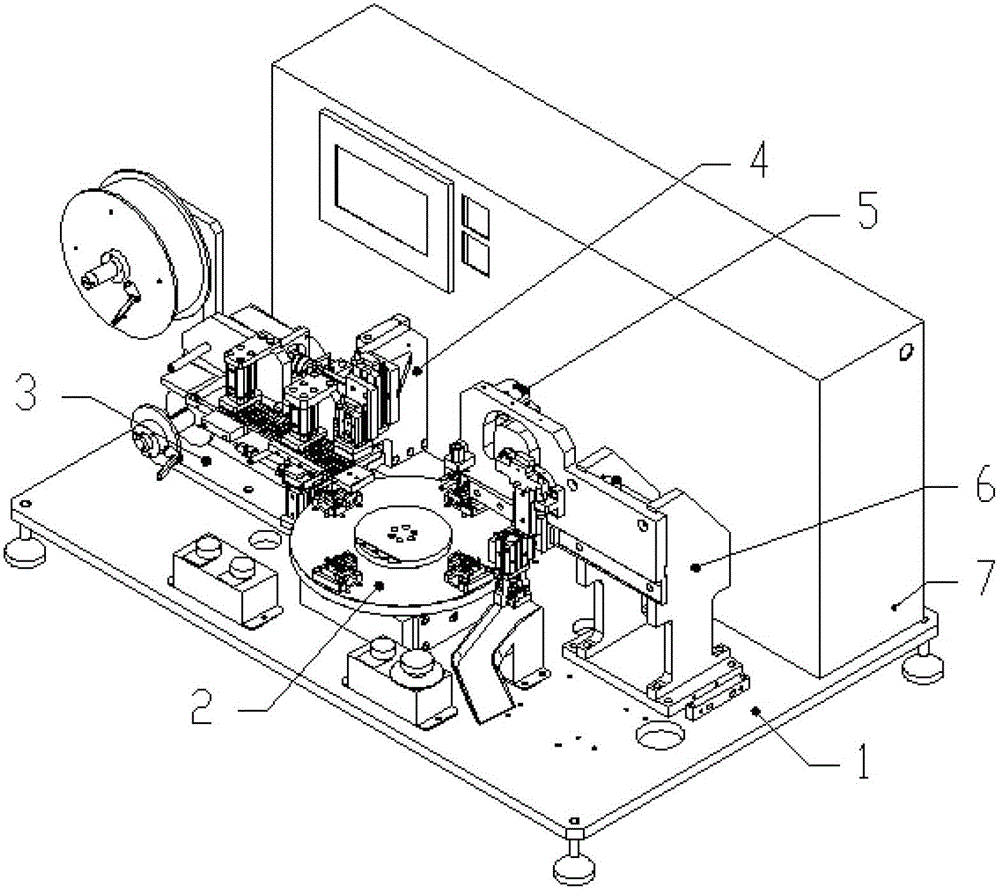

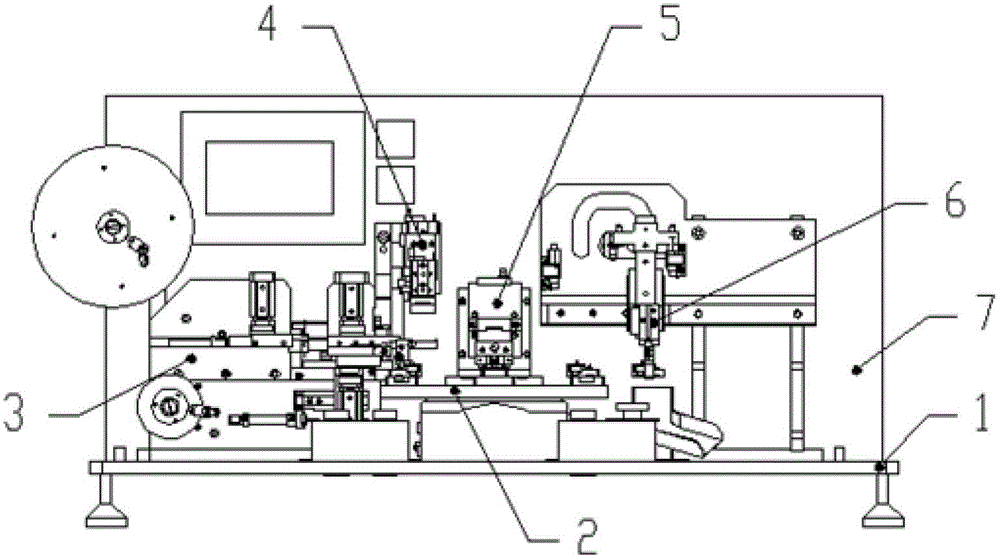

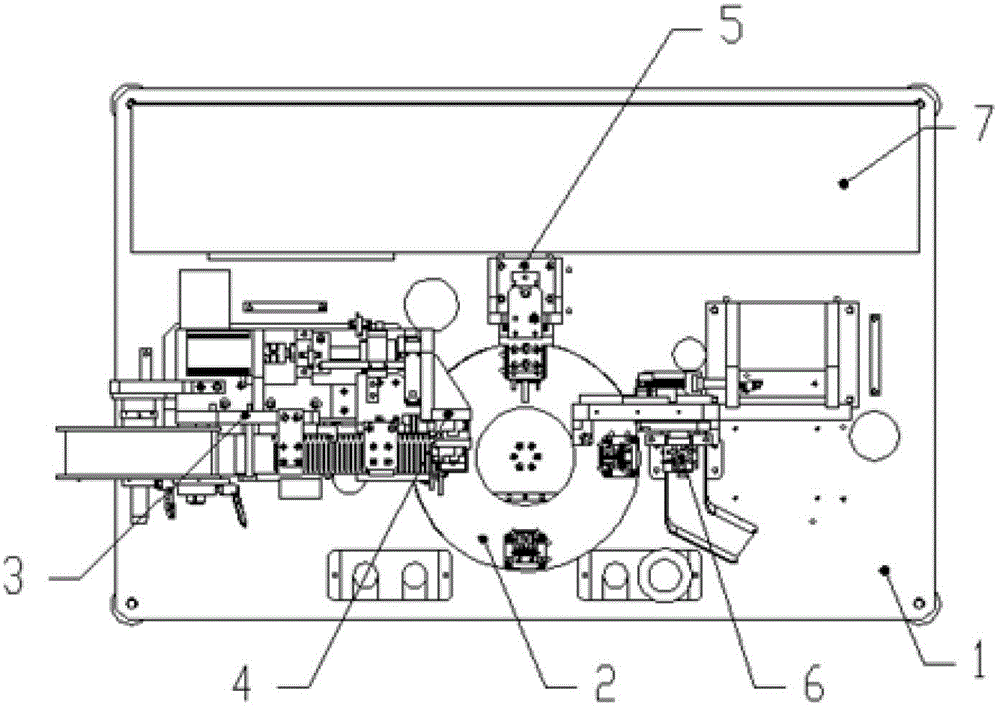

Adhesive tape sticking device

The invention discloses an adhesive tape sticking device, which comprises a rack, a carrier turntable instrument, an adhesive tape feeder, an adhesive tape sticking instrument, a component discharge instrument and a controller. Specifically, the adhesive tape feeder is used for adhesive tape feeding, the adhesive tape sticking instrument is disposed at the adhesive tape discharge end of the adhesive tape feeder, and a suction nozzle on the adhesive tape sticking instrument can suck an adhesive tape. The carrier turntable instrument is located on the rack, and can convey the carrier thereon to the place right below the suction nozzle so as to stick the adhesive tape by the suction nozzle. The component discharge instrument can send the carrier of an adhesive tape sticked product into a discharge flow channel for discharge. And the controller controls the work of each component. The adhesive tape sticking device provided by the invention realizes automatic peeling and sticking of adhesive tapes and automatic receiving of sticked products, achieves full automatic work, and has no need for manual operation. The adhesive tape sticking speed is fast, and the sticked adhesive tapes are accurate in positions and are firm. Manpower and space are saved, the production efficiency is improved, and production cost is reduced.

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

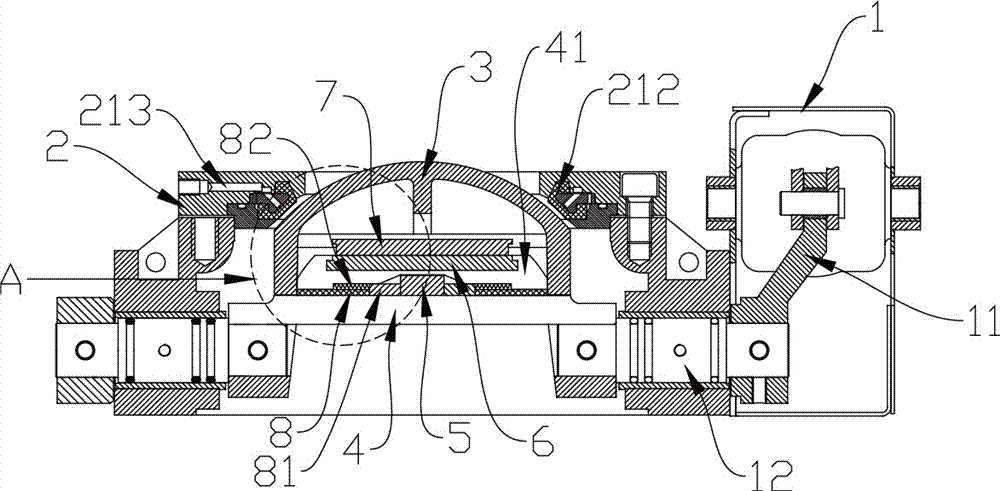

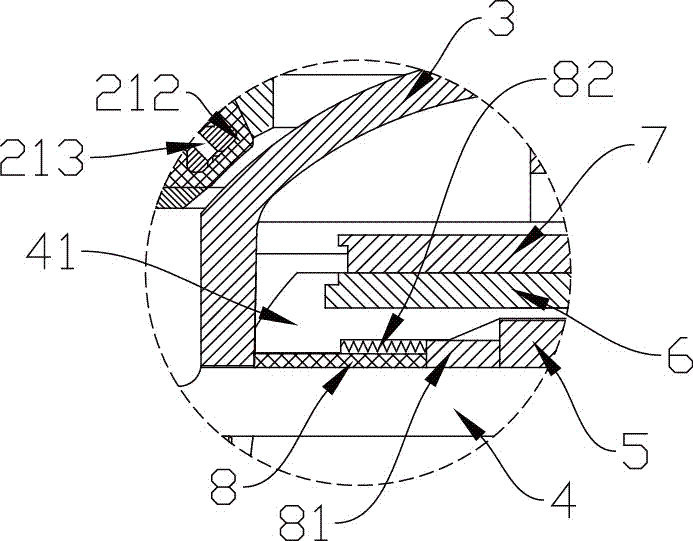

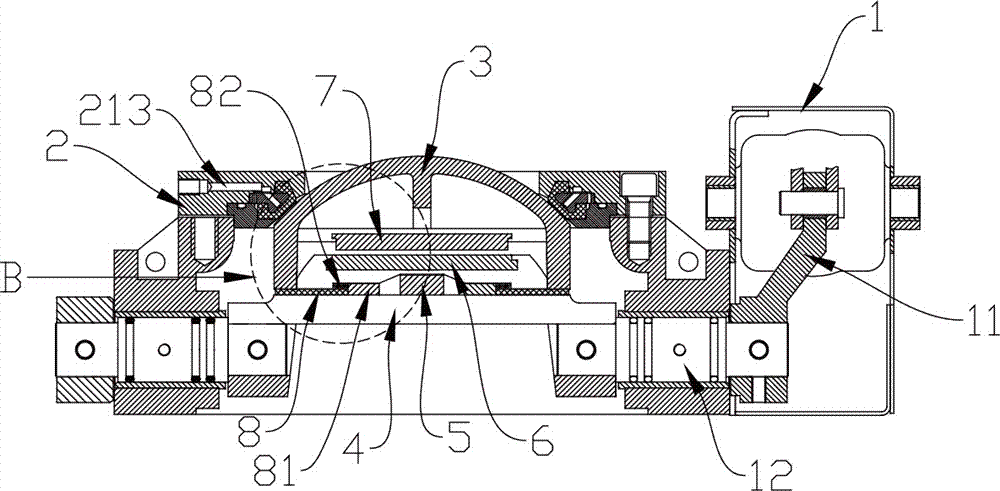

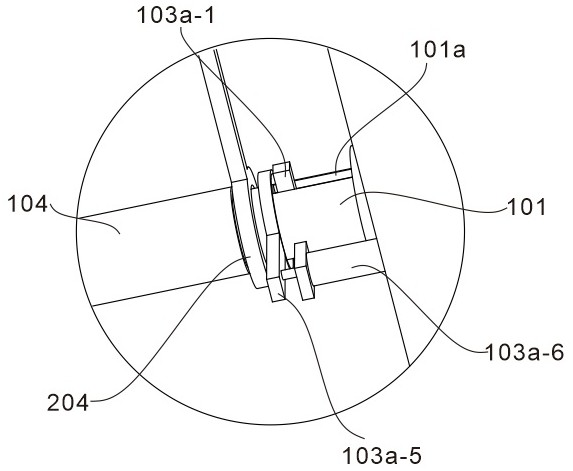

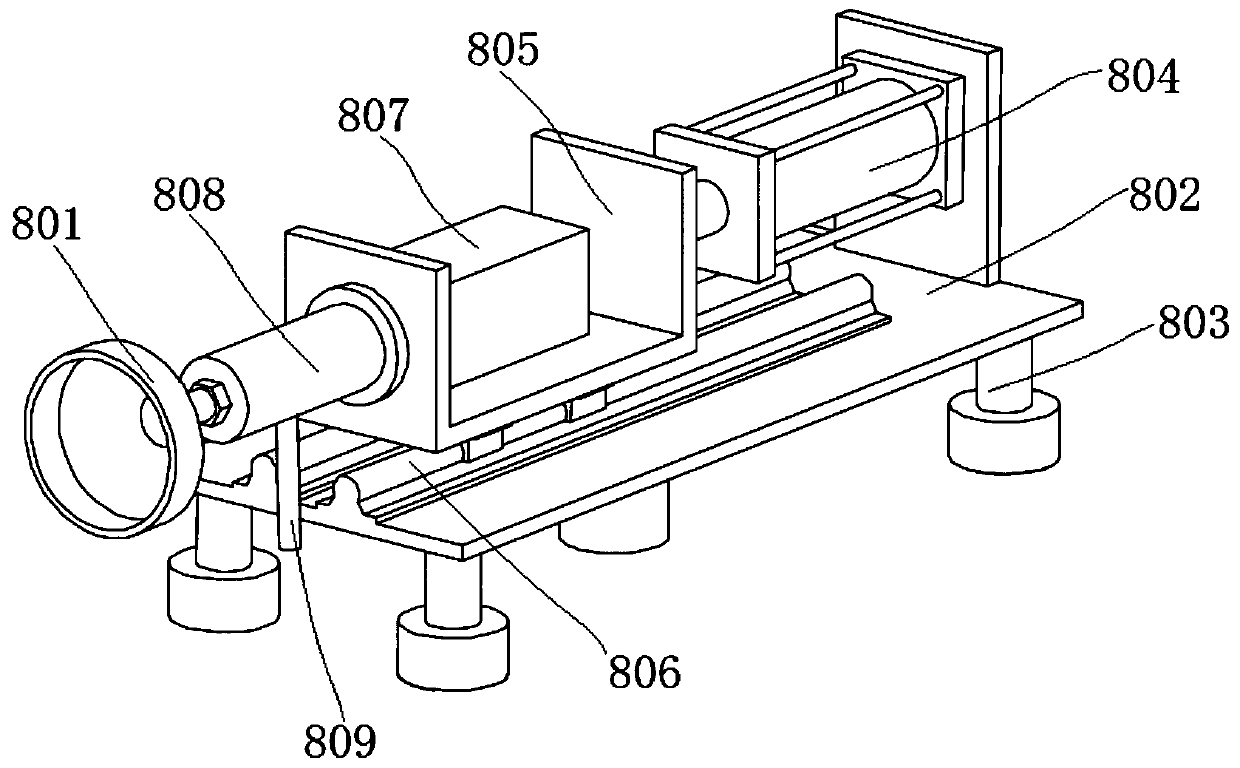

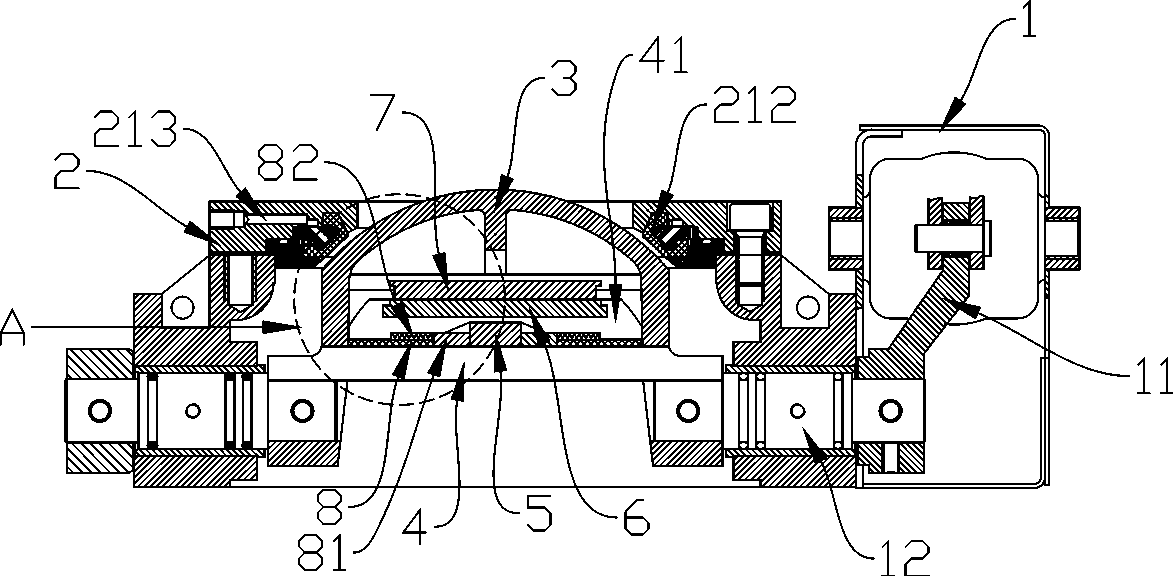

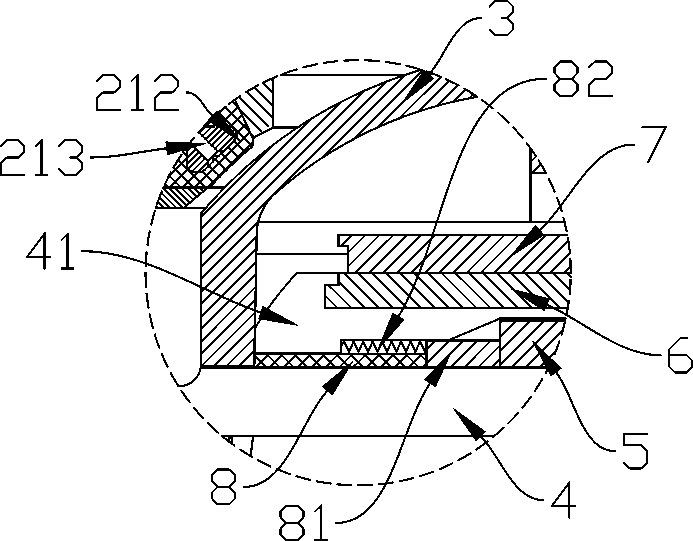

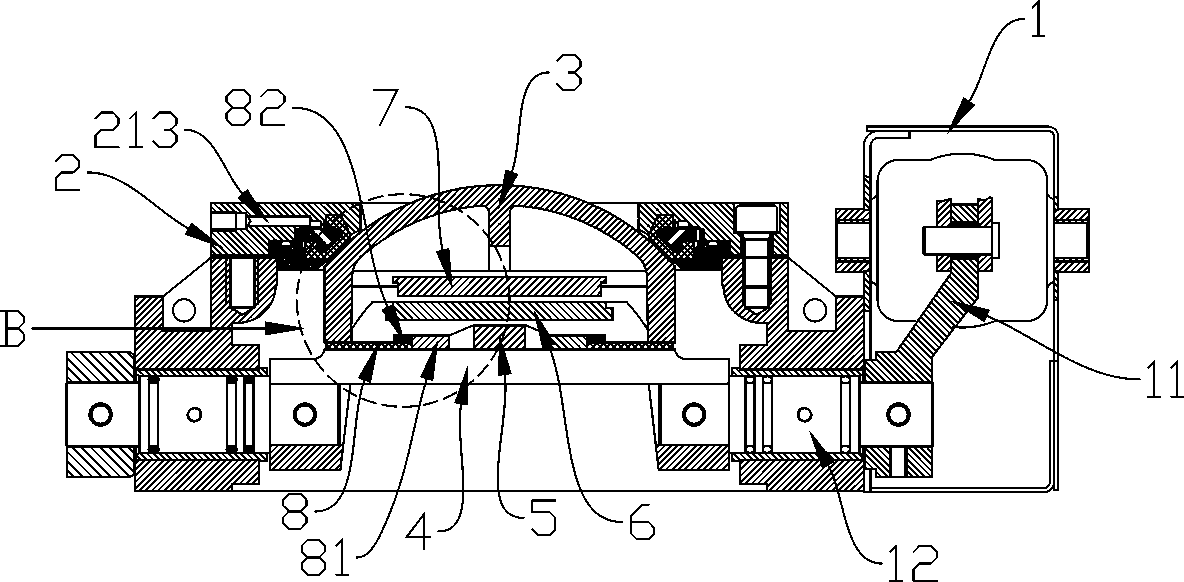

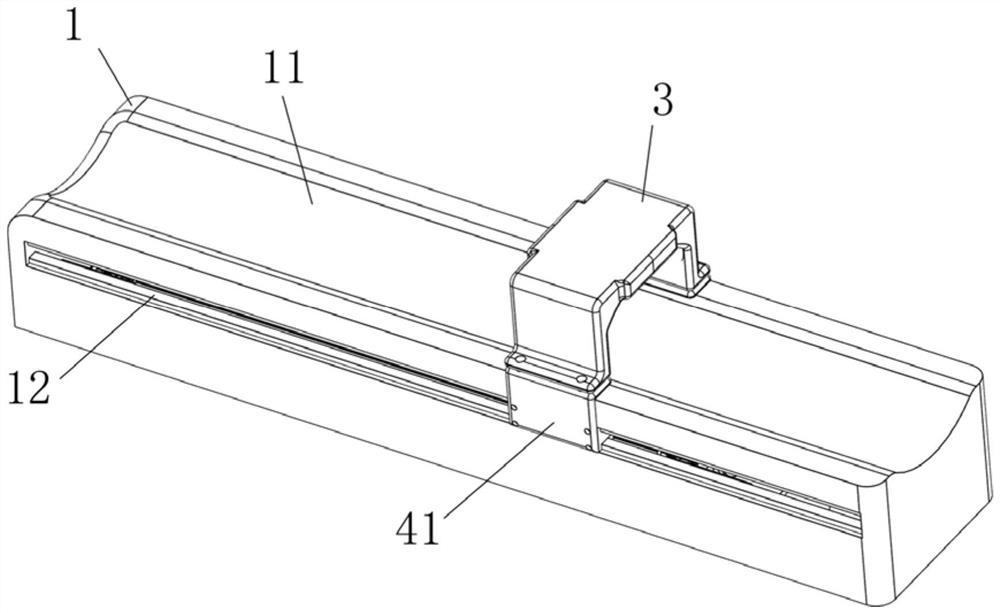

Dome valve for pneumatic conveying system and dome valve automatic control system

ActiveCN106996464ASolution to short lifeEasy to replacePlug valvesOperating means/releasing devices for valvesAutomatic controlControl system

A dome valve for a pneumatic conveying system comprises a valve body, a semi-spherical valve element arranged in the valve body, a drive crank used for driving the semi-spherical valve element to rotate and a pneumatic executing element connected with the drive crank. The valve body comprises an upper valve body and a lower valve body which are assembled together. The upper valve body is provided with a valve opening and a seal air bag. The lower valve body is internally provided with a valve element installation seat. The dome valve has the beneficial effects that in the valve opening and closing process, the semi-spherical valve element does not make contact with the seal air bag or generate friction with the seal air bag during rotating, so that wear is avoided; and meanwhile, the semi-spherical valve element is long in service life and convenient to replace.

Owner:ZHEJIANG GUTE PNEUMATIC MACHINERY

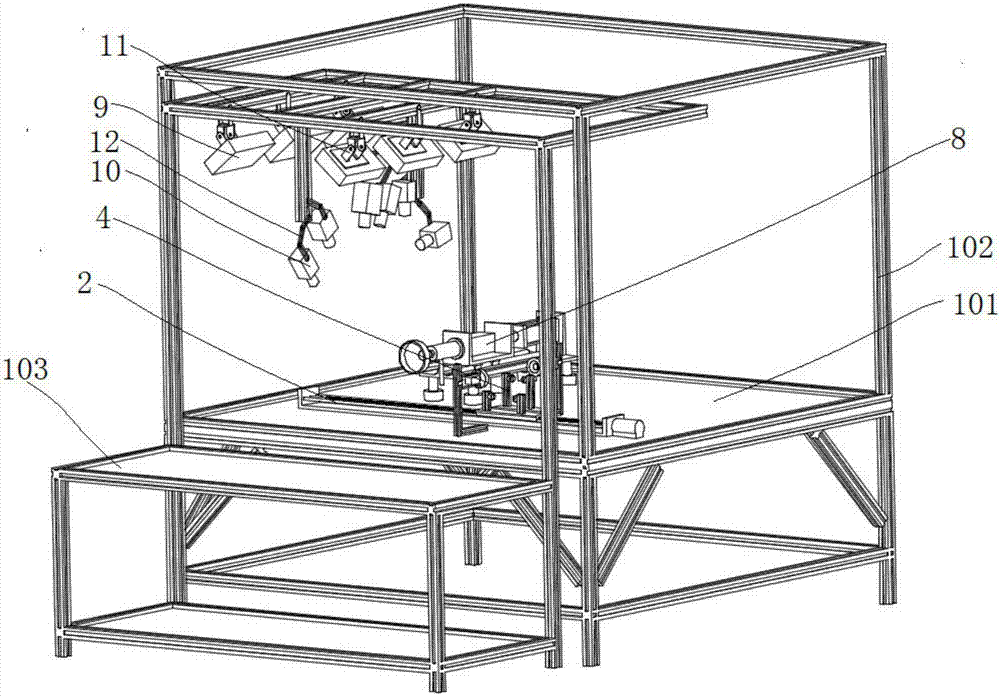

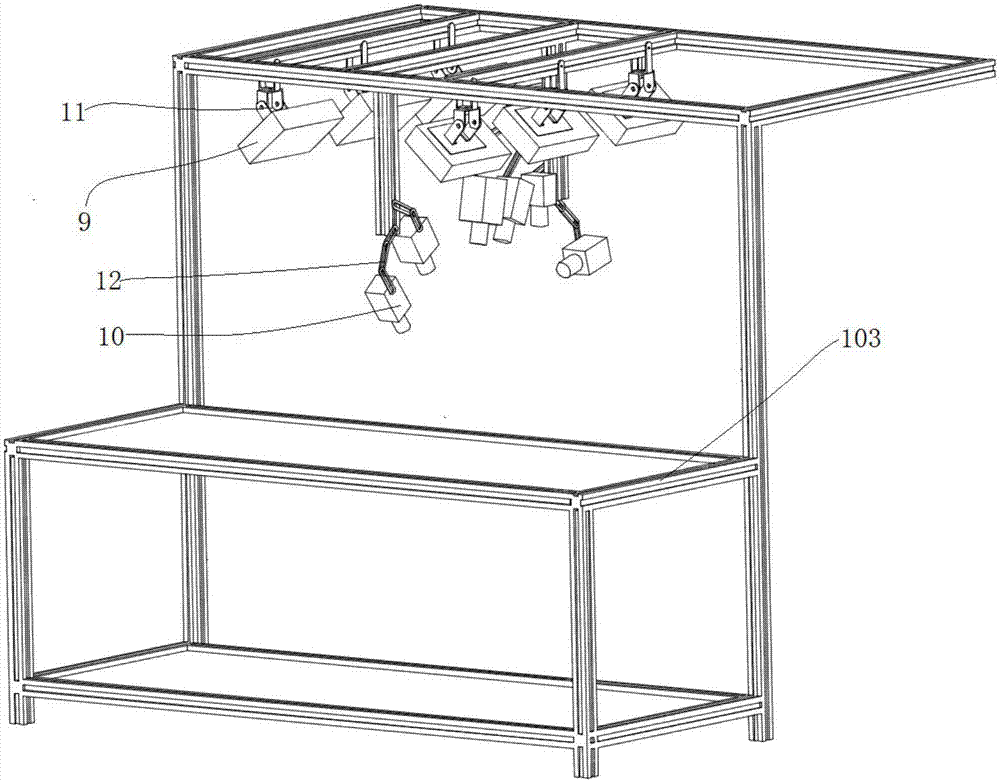

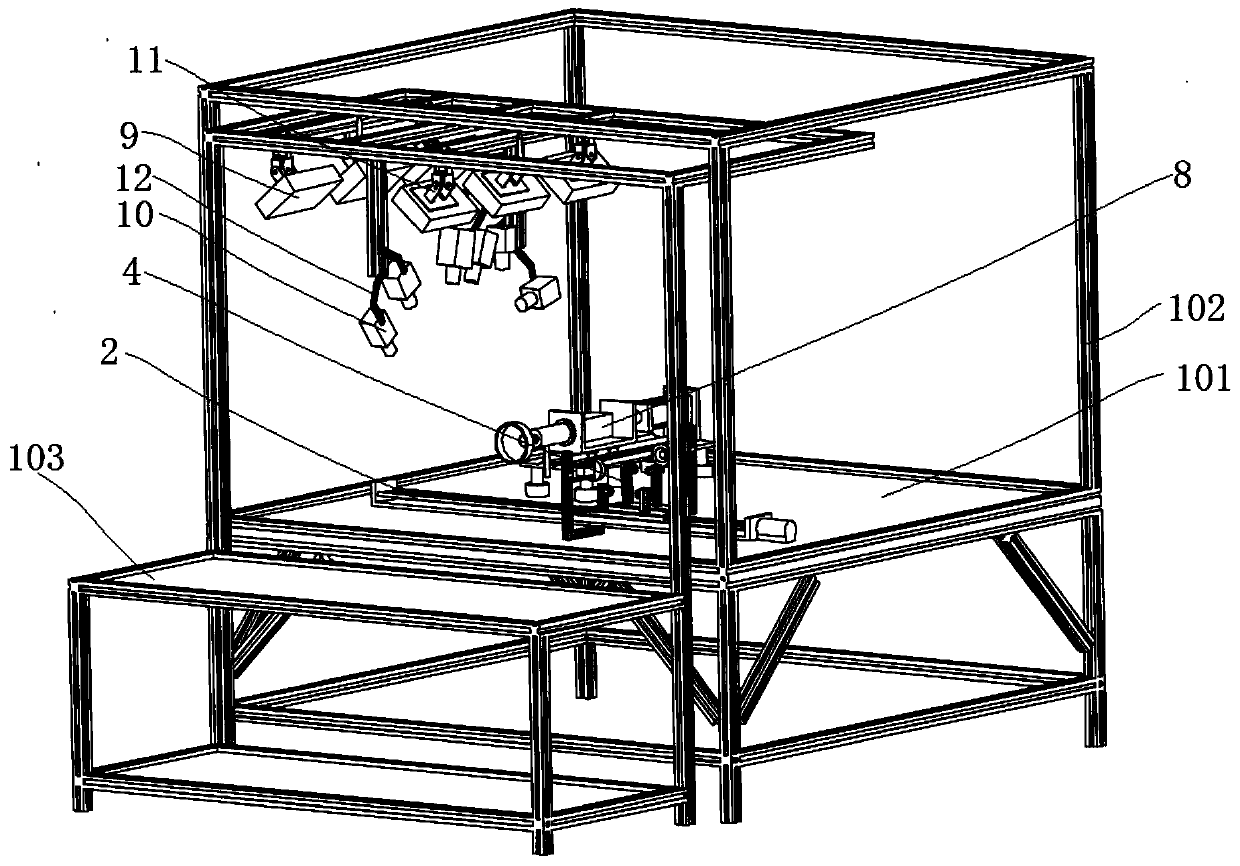

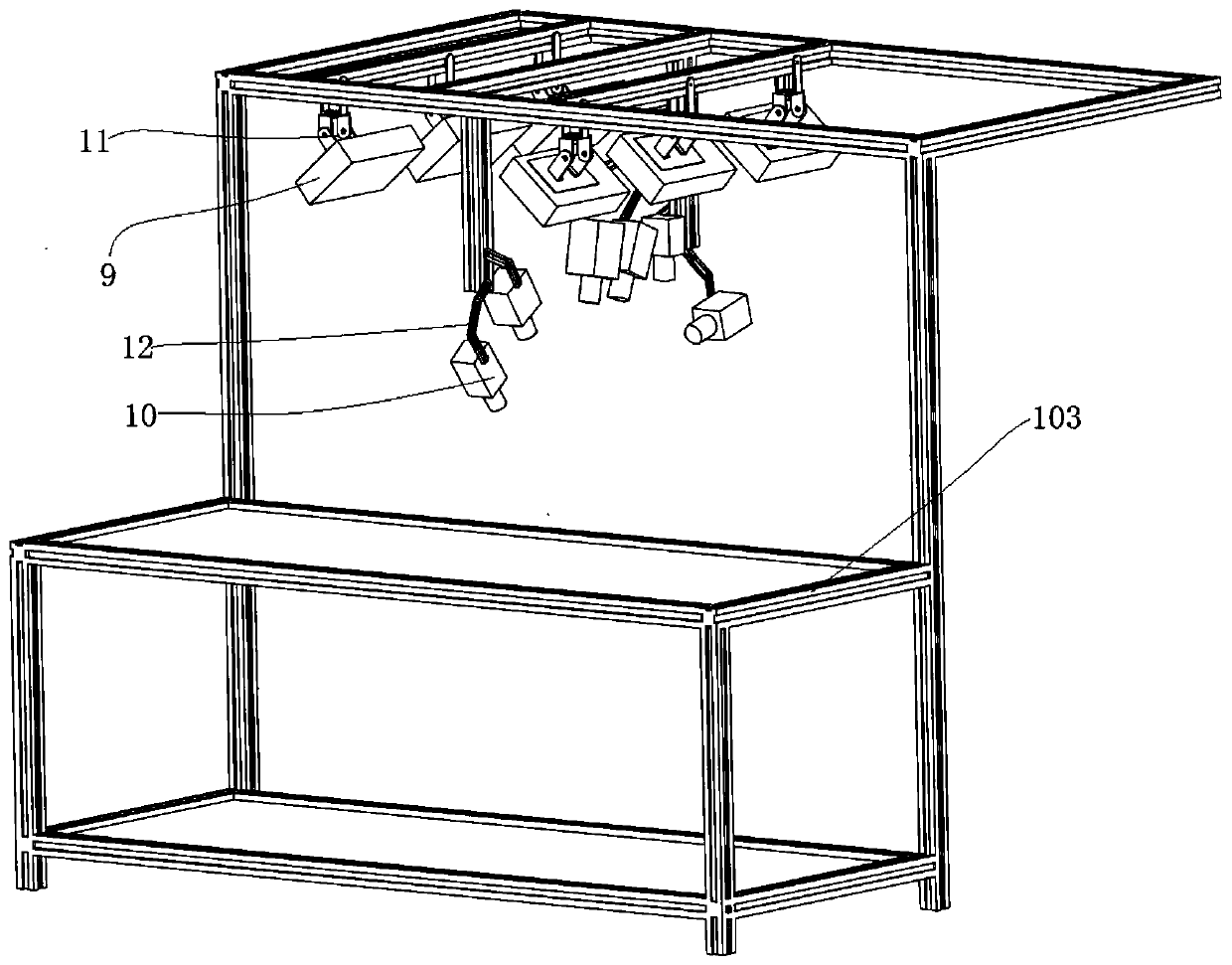

Visual detection method for disc suspension type ceramic insulator

ActiveCN107179323AEasy to operateAccurate Defect DetectionOptically investigating flaws/contaminationPattern recognitionReference database

The invention discloses a visual detection method for a disc suspension type ceramic insulator. The method comprises the following steps: 1) establishing feature libraries of various defects; 2) confirming a numerical range of each type of defects in the feature library, and further refining the defects to establish a more detailed defect reference database to determine the type and specific state of a defect; 3) determining if a to-be-detected ceramic insulator is at a detection position; 4) performing image processing on collected image data; 5) utilizing a threshold segmentation principle to process and analyze the image processed and analyzed in the step 4), comparing the processing and analysis result with the defect reference database established in the step 2) one by one, if matching match is found, sending an unqualified signal of the ceramic insulator, and if not, sending a qualified signal of the ceramic insulator. The visual detection method is convenient in operation, is capable of greatly reducing labor intensity and increasing the detection working efficiency and is capable of accurately detecting the defects of the ceramic insulator.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

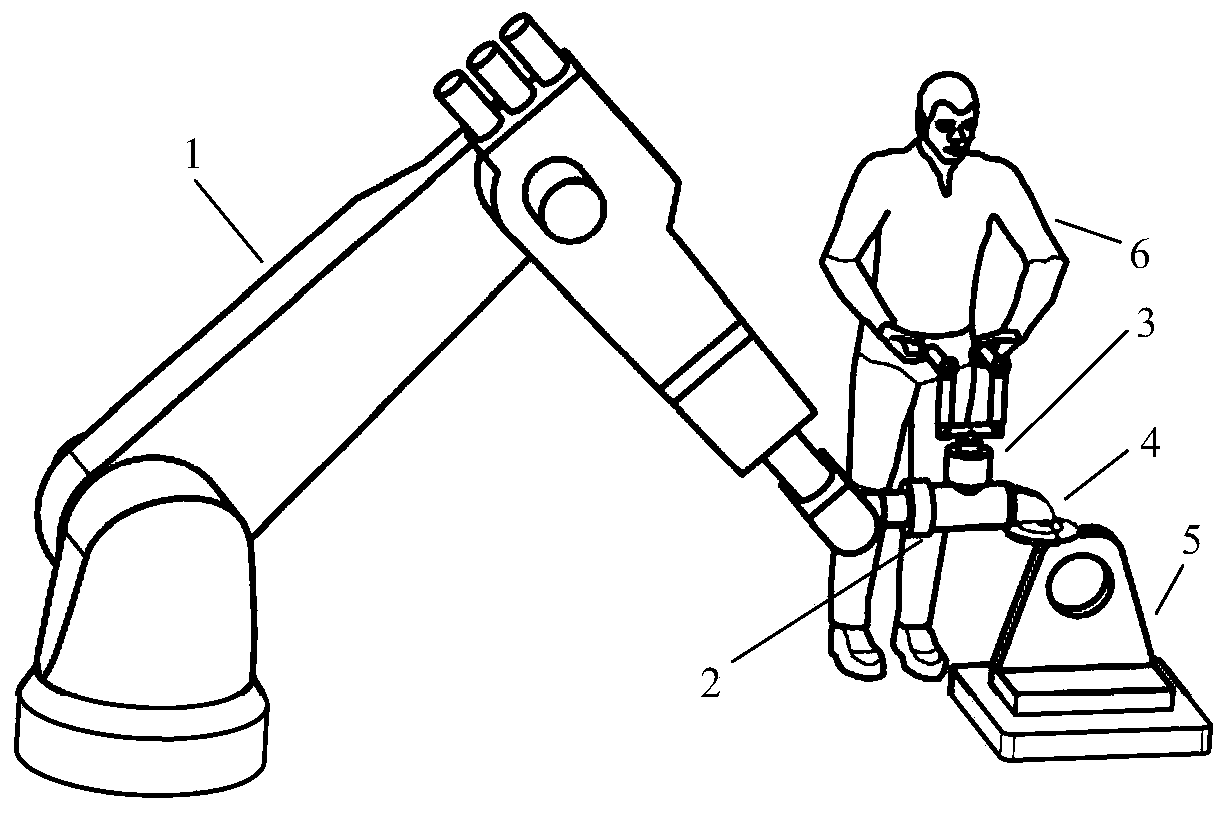

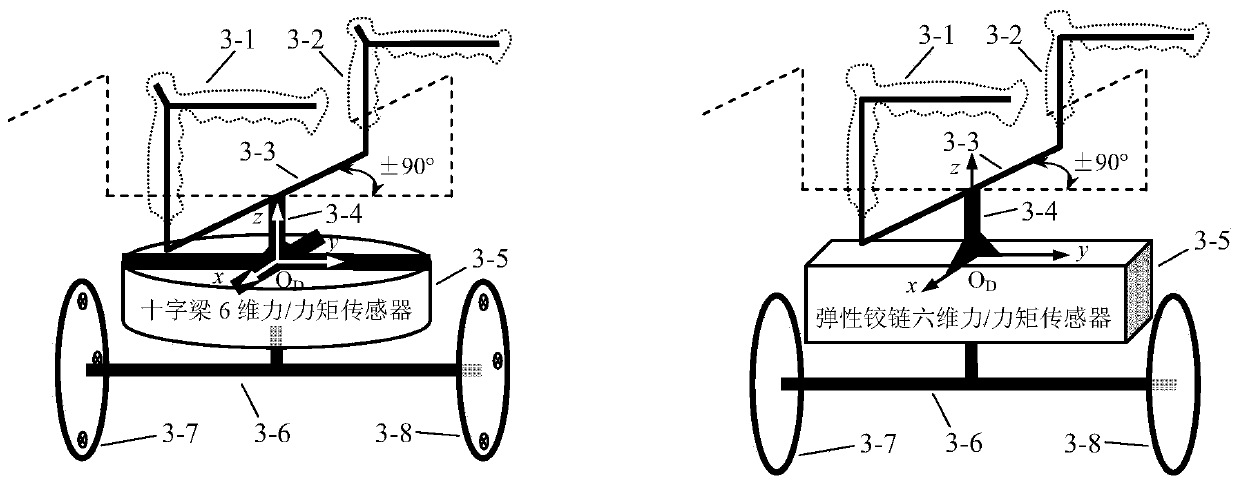

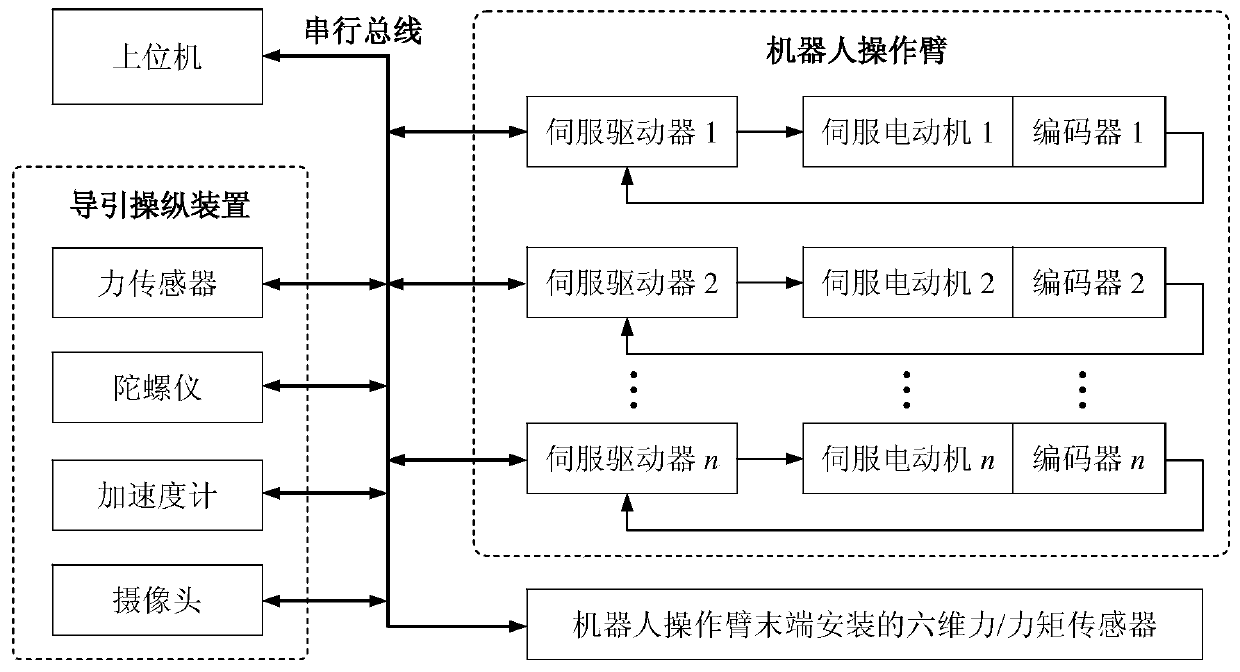

Guide operating system of robot operation arm, compliant operation control method thereof and demonstration learning method thereof

ActiveCN110653801AReduce labor intensityImprove efficiencyProgramme-controlled manipulatorAccelerometerGyroscope

The invention discloses a guide operating system of a robot operation arm, a compliant operation control method of the guide operating system and a demonstration learning method of the guide operatingsystem, and relates to the field of man-machine collaborative operation system development. The guide operating system of the robot operation arm, the compliant operation control method of the guideoperating system and the demonstration learning method of the guide operating system are used for solving the problems that in an existing man-machine collaborative operation system, an operation handle is fixed, all-directional operation cannot be achieved, and the compliant operation control method and the intelligent demonstration learning method do not exist. The guide operating system comprises two mechanical interfaces, a rotatable operation handle and sensors such as a force sensor, a gyroscope and an accelerometer. In the compliant control process, a virtual spring damping model is utilized to calculate the reference movement of the operation, and the discordance amount between an operator and a robot is compensated by a force control method. The system state transition of the operation process serves as training data, and a deep learning system with a four-layer structure is used for learning the operation movement and force interaction process of the operator. The operator and robot collaborative operation can organically combine the advantages of the operator and the robots, and therefore the labor intensity of the operator can be reduced in the automatic assembling andpolishing operation on the premise that the operation quality is guaranteed, the working efficiency can be improved in the automatic assembling and polishing operation on the premise that the operation quality is guaranteed, and the guide operating system of the robot operation arm, the compliant operation control method of the guide operating system and the demonstration learning method of the guide operating system have the broad application prospect.

Owner:HARBIN INST OF TECH

Buckle assembling device

PendingCN108942160ARealize automatic assemblyAvoid missed inspectionsMetal working apparatusEngineeringInductor

Owner:四川科思精密模具股份有限公司

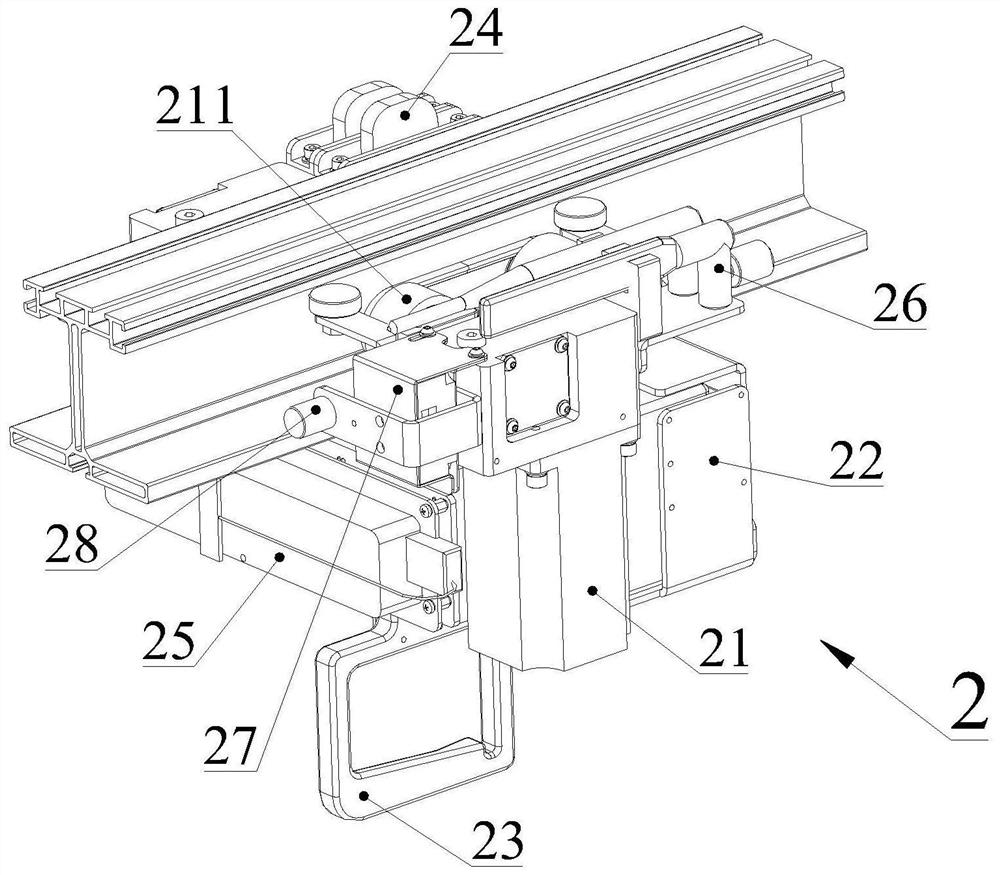

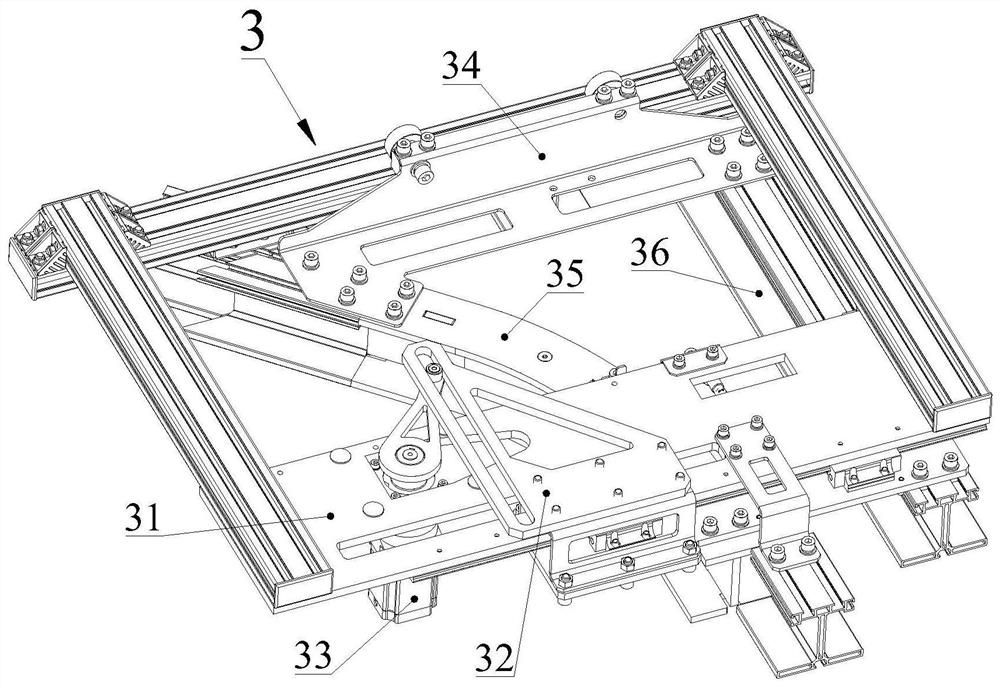

Suspended transfer robot system and self-moving transfer robot

The invention provides a suspended transfer robot system and a self-moving transfer robot. The system comprises a main suspension rail which is laid in a preset working area and forms a closed-loop structure; a bale loading rail which is arranged in the working area and can be connected with the main suspension rail in a shunting and converging manner; at least one sorting slide way connected withthe main suspension rail, wherein a gap is formed between each sorting slide way and the bale loading rail; and at least one transfer robot, wherein the transfer robots shuttle back and forth in theworking area along the main suspension rail and the bale loading rail in a self-driving mode, so that target goods from the bale loading rail are transferred to the sorting slide ways through the mainsuspension rail to be sorted and packaged.

Owner:HEMA (CHINA) CO LTD

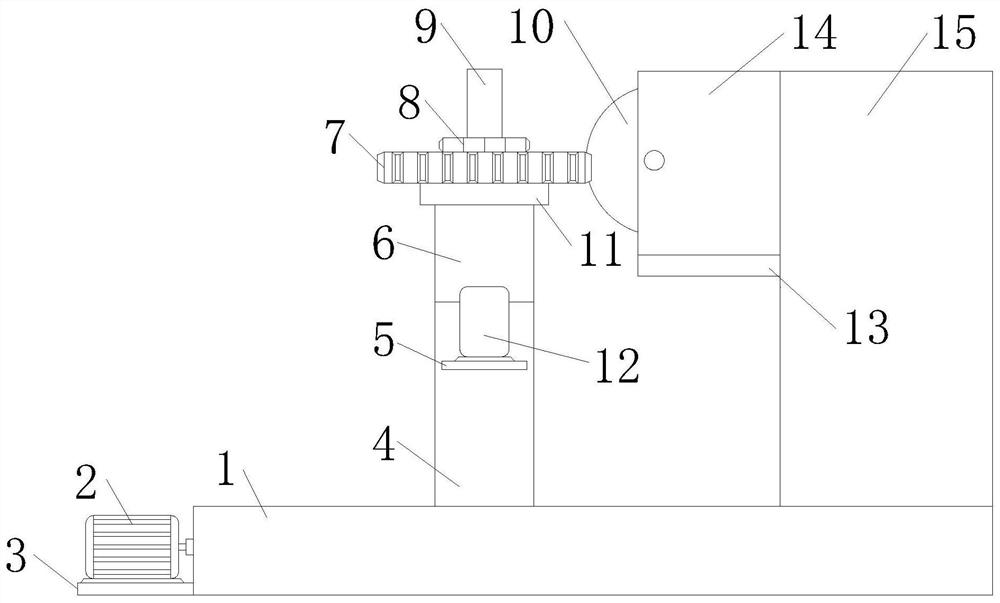

Fruit peeling machine and peeling method

Disclosed are a fruit peeling machine and a peeling method. The fruit peeling machine comprises a base, a peeling execution part, a fruit picking and placing part, a fruit storage box and a fruit peelstorage tank; a motor rotates to drive a gear to rotate to cooperate with an intermittent mechanism, the peeling execution part, the fruit placing part and the fruit picking part cooperate with one another, through one-third rotation of a three-jaw chuck, a cutter head peels an apple, and during backward drawing, the chuck rotates to make a new apple be turned to the position of the cutter head;meanwhile, a rubber wheel below the three-jaw chuck is in contact with a wheel of an independent small motor, rotation begins to achieve repeated automatic cutting, and the cutter head is fixed by a spring and fits an external curve of the apple, so that the cut-off fruit peel has a certain thickness. A fruit placing mechanism and the fruit picking part synchronously work to send peeled fruits into the storage box, automatic fruit peeling is achieved, and the peeling efficiency and quality are improved.

Owner:湖南果月食品有限公司

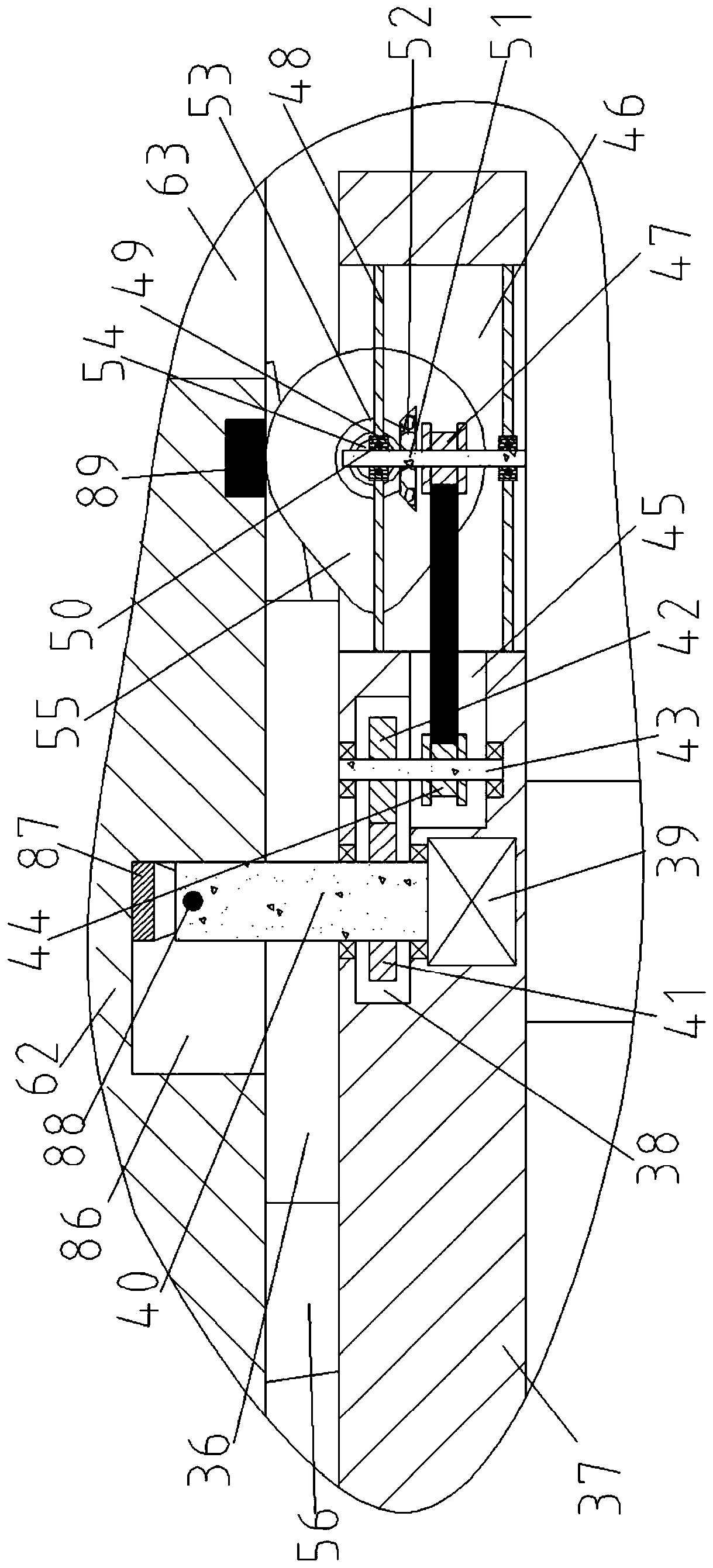

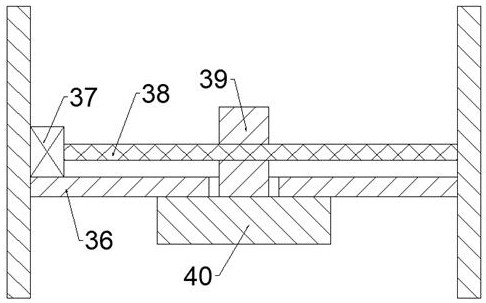

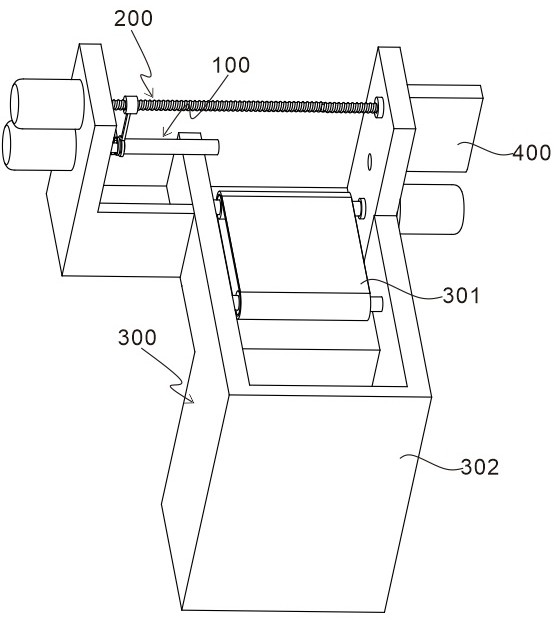

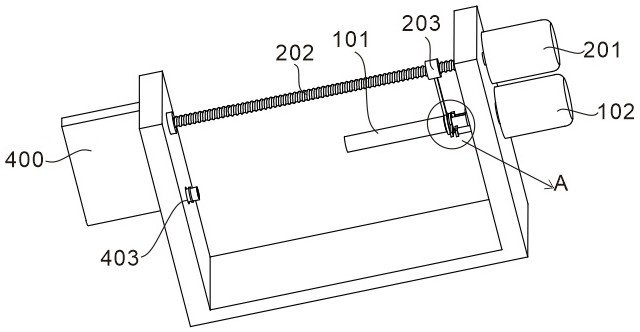

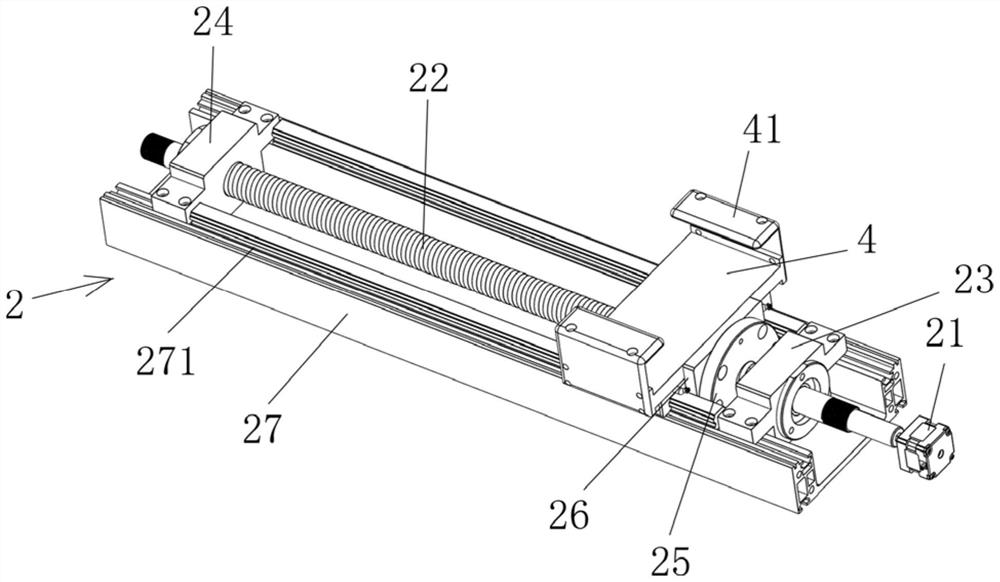

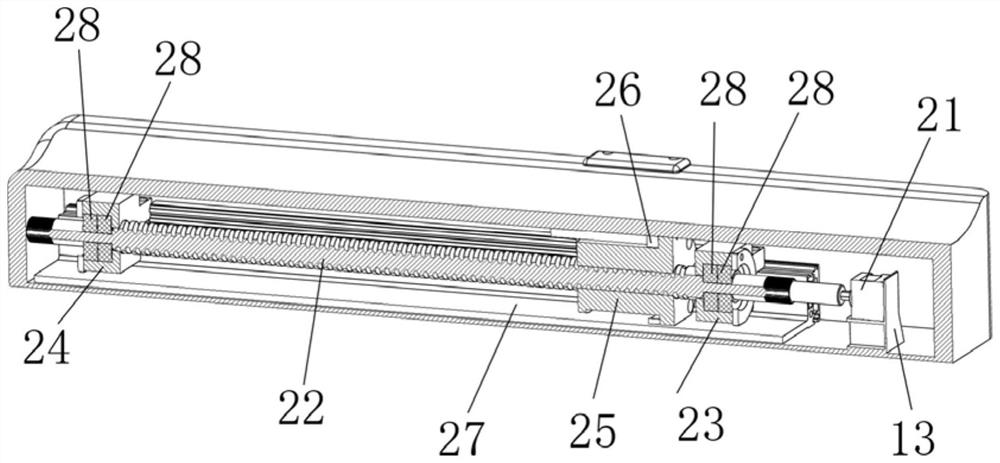

Metering type lead screw color master proportional valve

The invention discloses a metering type lead screw color master proportional valve which comprises a feeding assembly, a discharging assembly and a mixing valve assembly, wherein the feeding assembly is used for quantitatively conveying a color master in the discharging assembly into the mixing valve assembly; the feeding assembly comprises a motor, wherein the motor drives a feeding lead screw to rotatably feed; the discharging assembly comprises a color master hopper used for storing the color master, a discharging chamber is arranged at the bottom of the color master hopper, and the whole color master hopper is mounted on a horizontal sliding block base; the discharging chamber comprises an inlet and an outlet, wherein a discharging pipe is mounted at the outlet, and the end part of the feeding lead screw is arranged in the discharging pipe after the feeding lead screw extends to the outlet of the discharging chamber from the inlet of the discharging chamber; the mixing valve assembly comprises a static base, wherein the interior of the static base is hollow, a distributing cone with a cavity is arranged in the static base, and a raw material inlet is formed in a position, which corresponds to the position of the top end of the distributing cone, of the top end of a shell of the static base; and an opening communicated with the cavity of the distributing cone is formed in the bottom of the distributing cone.

Owner:明利机电(深圳)有限公司

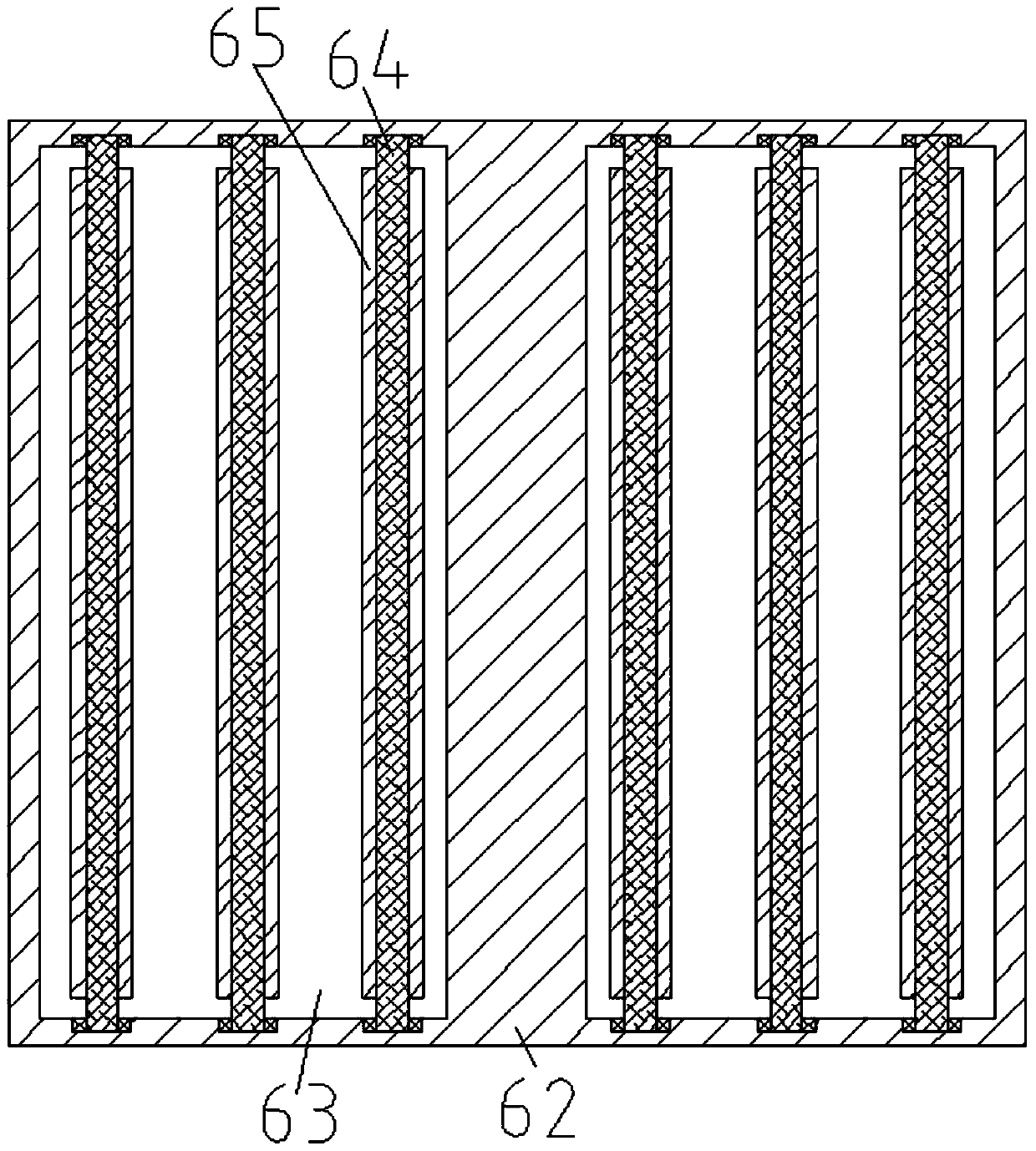

Plywood pressing machine

ActiveCN110228112AReduce the bending effectReduce congestionPlywood pressesVeneer pressesManufacturing technologyEngineering

The invention discloses a plywood pressing machine. The plywood pressing machine comprises a machine main body, a wood inlet which penetrates through the right is fixedly arranged in the machine mainbody, a wood initial pressing groove is formed in the inner wall of the upper side of the wood inlet, a hinged connection block is fixedly arranged on the inner wall of the upper side of the wood initial pressing groove, a pressing rod is hinged to the hinged connecting block in a hinged mode, a pressing wheel base is fixedly arranged at the lower end of the pressing rod, a pressing wheel capableof freely rotating is fixedly arranged in the pressing wheel base, a first spring fixing block and a second spring fixing block are fixedly arranged on the inner wall of the upper side of the pressingrod and the upper side of the wood initial pressing groove respectively. In the manufacturing technology of the existing plywood, due to the fact that the manufacturing procedures of the plywood arevarious, the processing mode that most of the plywood is manually combined with one another is adopted, the processing efficiency of the processing mode is slightly lower than that of a full-automaticmachining mode, and the full-automatic manufacturing method of the high-efficiency and high-quality plywood is provided.

Owner:山东绿树源木业有限公司

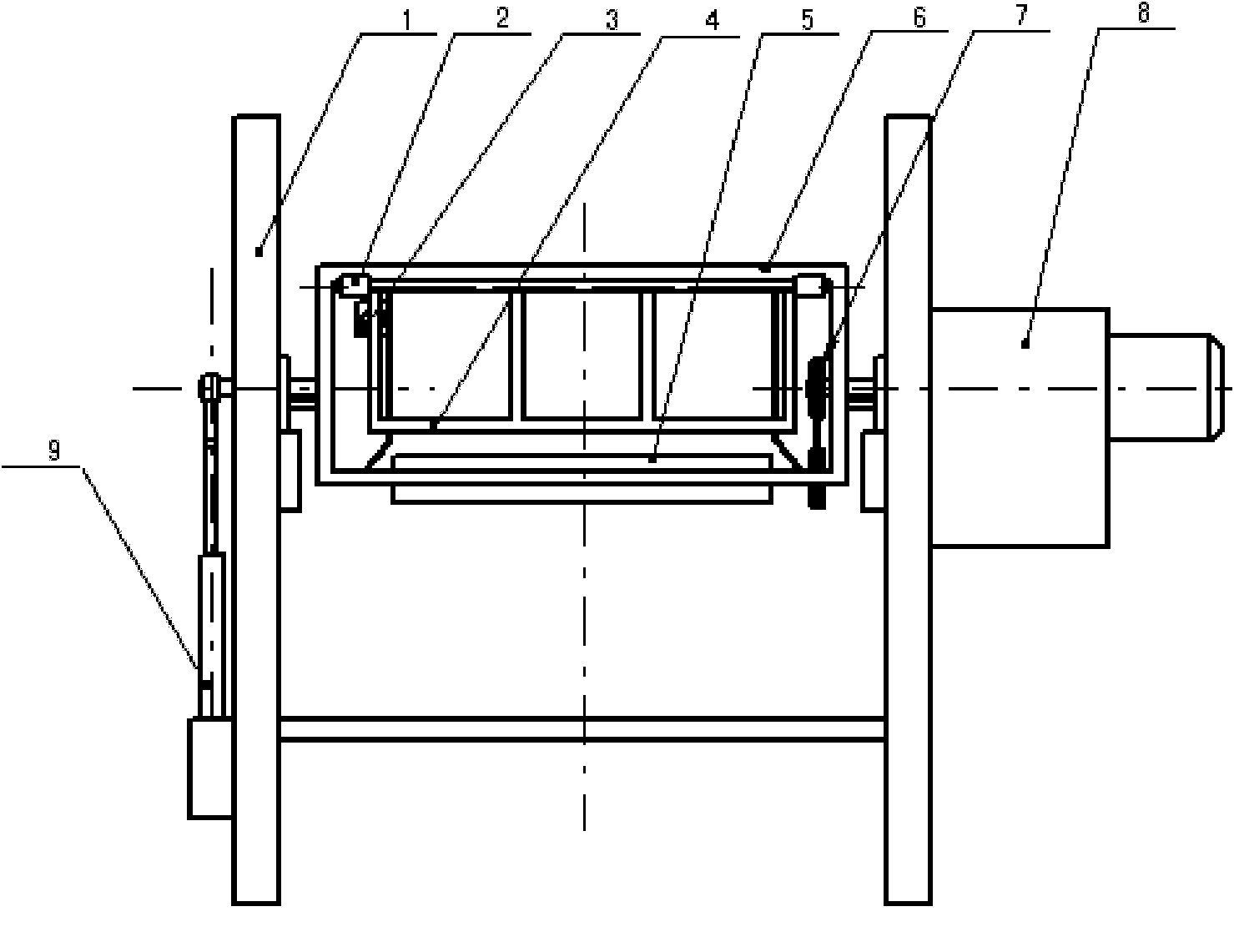

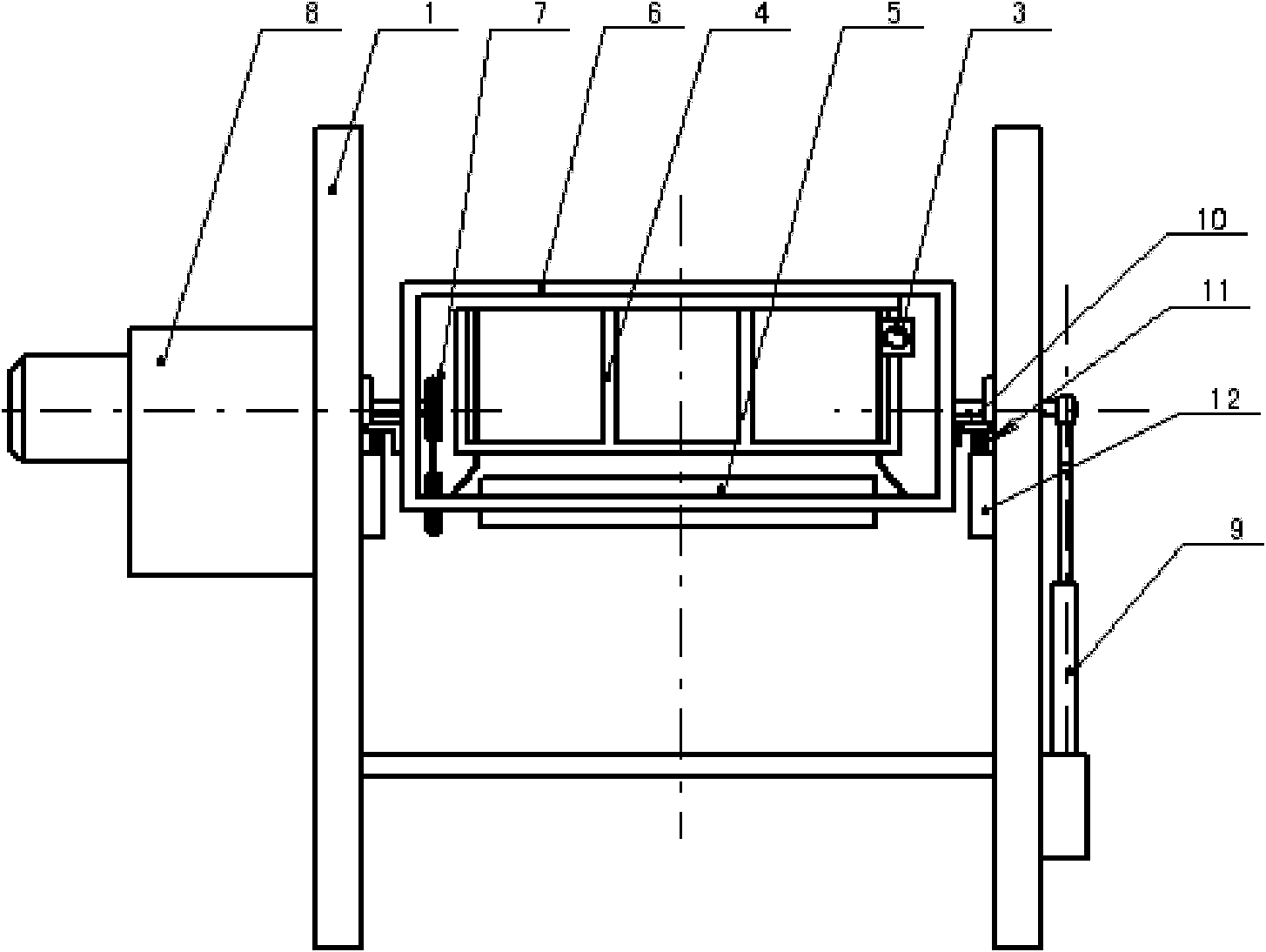

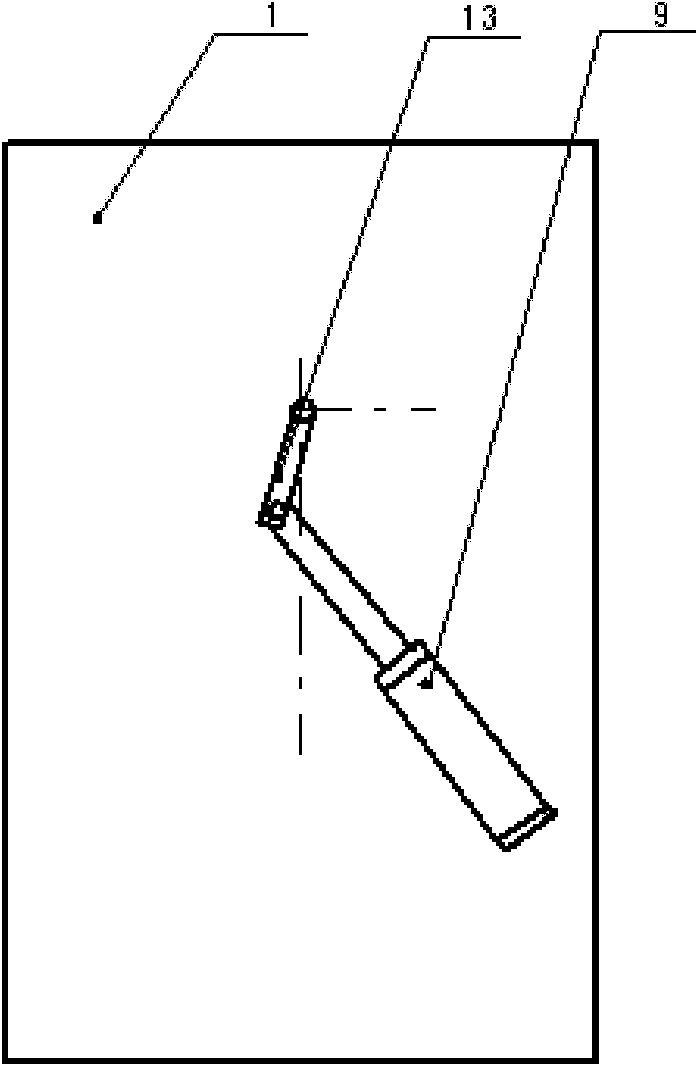

Automatic sand pouring machine for hub

ActiveCN102126187ASimple structureIncrease productivityAbrasive machine appurtenancesEngineeringDrive motor

The invention relates to an automatic sand pouring machine for a hub. The machine comprises support plates on two sides, a wheel frame, a transmission roller, a drive motor and a cylinder, wherein the wheel frame is fixed between the support plates on two sides horizontally through a shaft; the wheel frame is of a frame type structure, and transmission shaft rows are horizontally arranged at the bottom of the wheel frame; a baffle is hinged on the front part of the wheel frame, and is driven through a baffle cylinder frame which is fixed on one side in the wheel frame; and a chain wheel transmission group is arranged on the other side in the wheel frame, drives the transmission roller rows to synchronously run, and is driven by the drive motor which is fixed outside the support plate which is on the same side as the chain wheel transmission group; the cylinder is fixed on the support plate on the other side, the extending end of the cylinder drives an oscillating arm; and oscillation of the wheel frame in a certain angle is realized by a mode that the oscillating arm drives a wheel frame shaft. The sand pouring machine can realize full-automatic sand removing for the hub by adopting transmission modes of chain drive and cylinder drive through a photoelectric sensor and other devices, has the advantages of scientific and reasonable design and good environmental protection effect, is suitable for sand removal for the hub and other situations of removing attachments by adopting a tilt oscillation mode.

Owner:TIANJIN LIZHONG GRP CO LTD

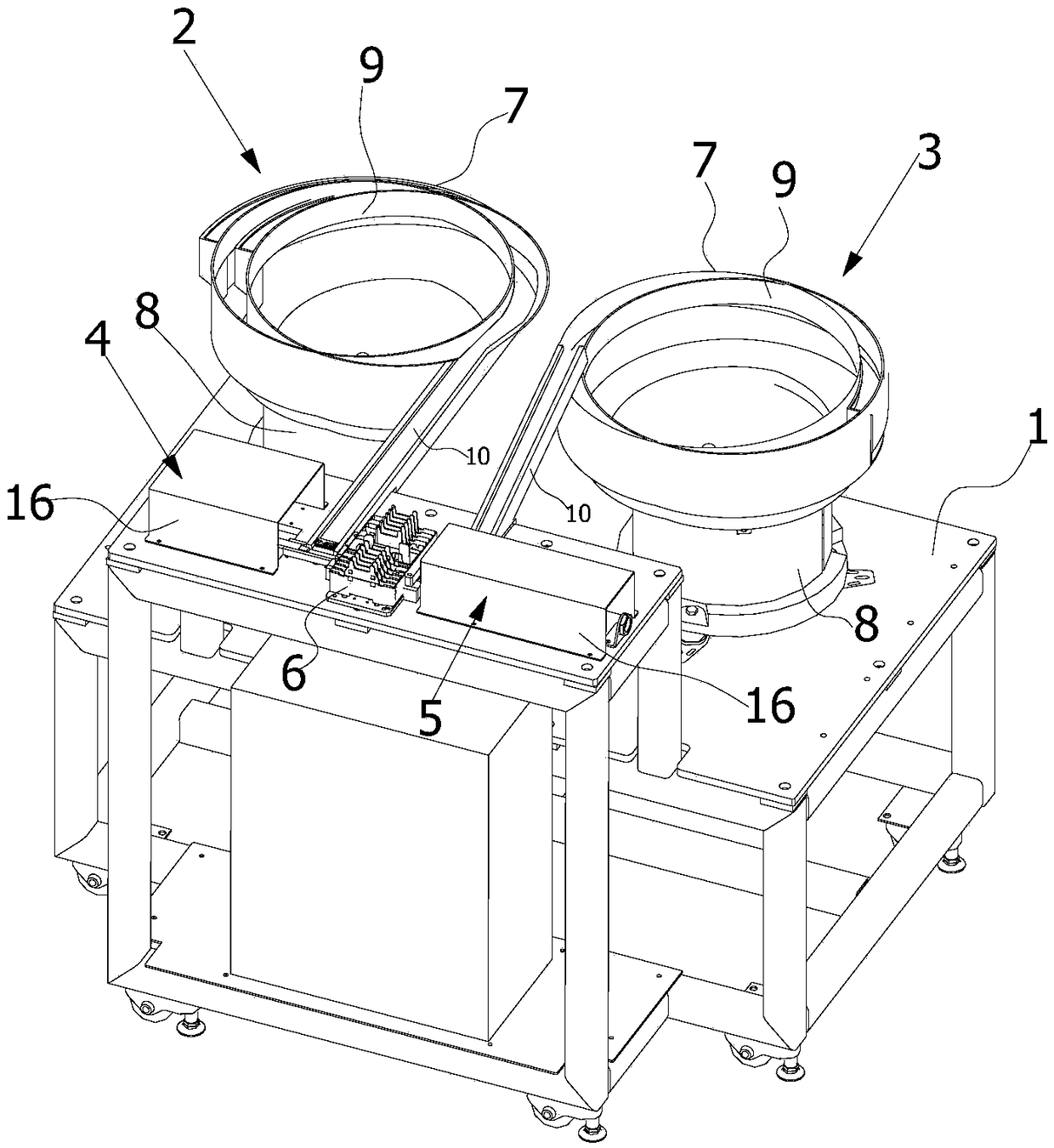

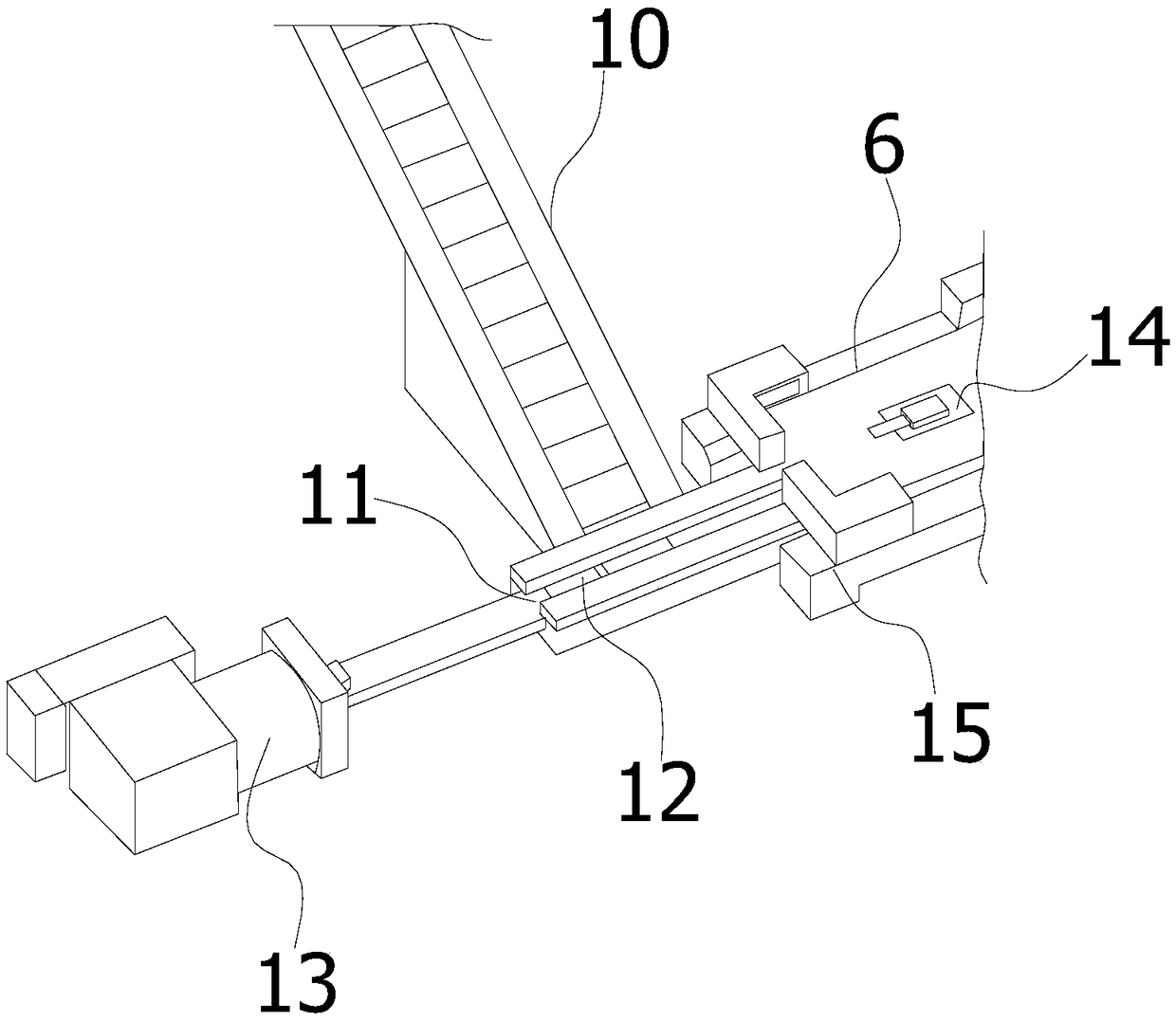

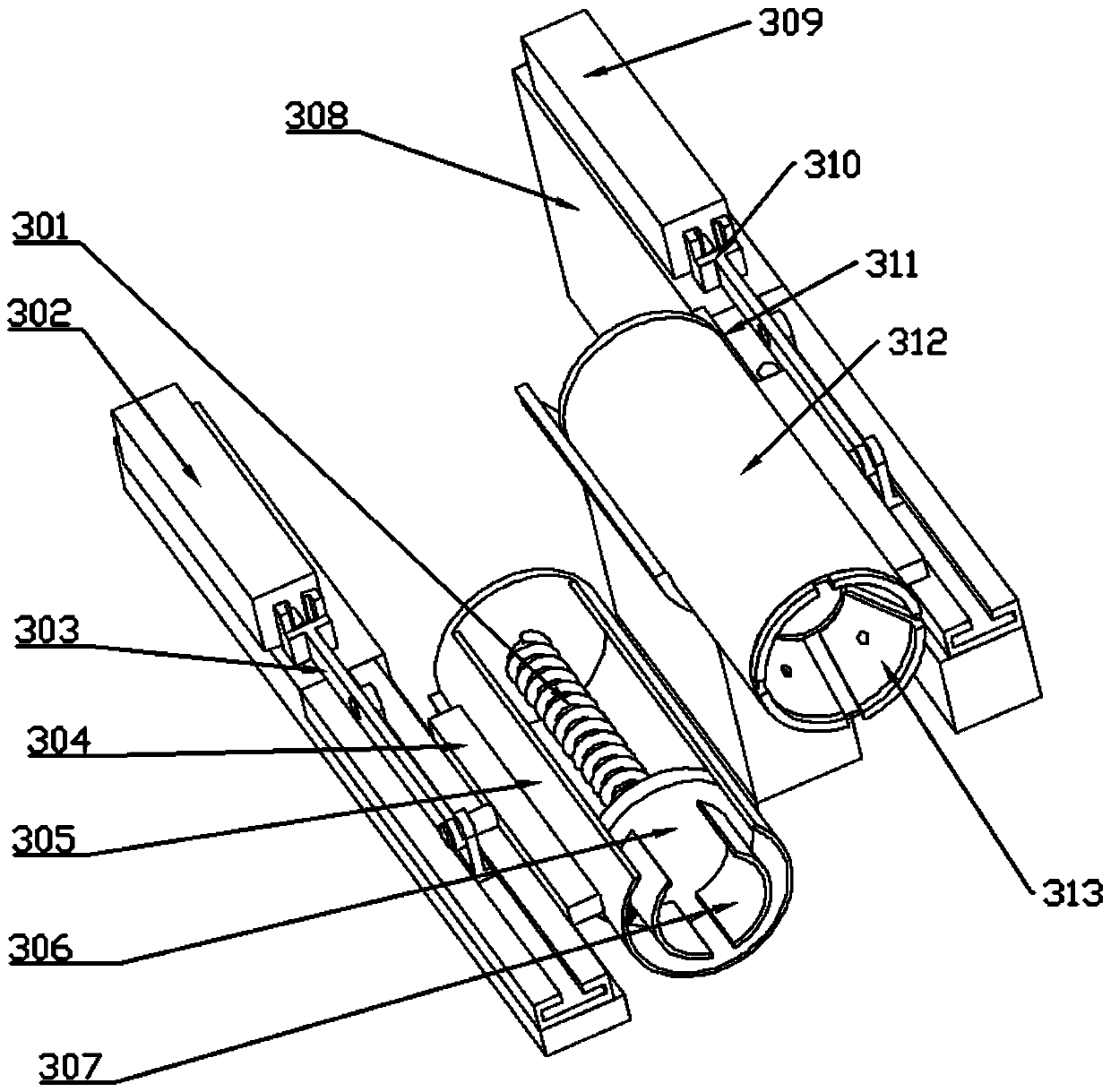

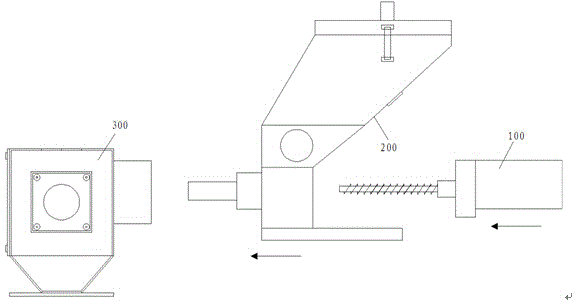

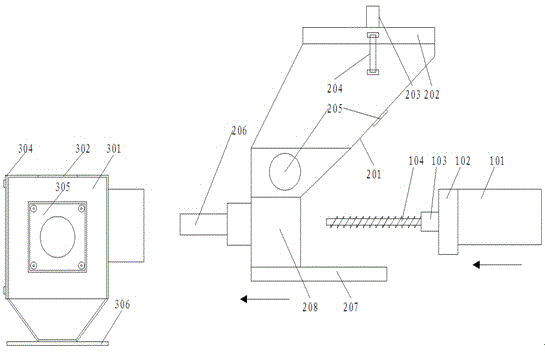

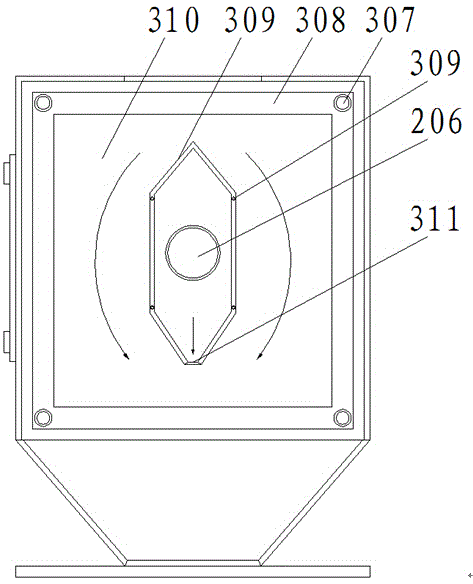

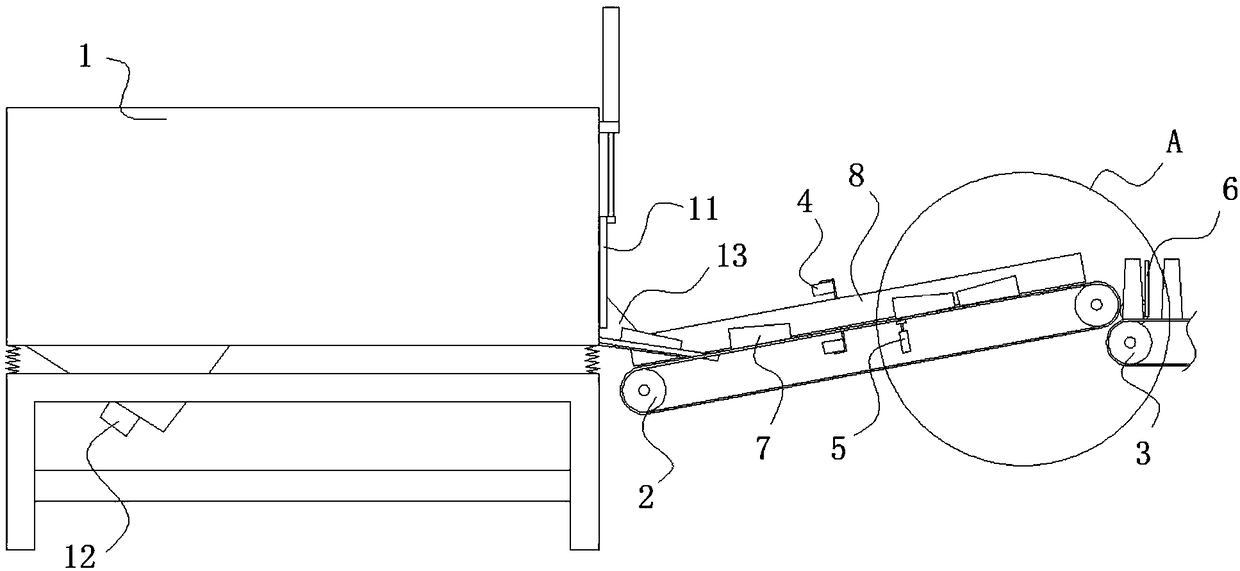

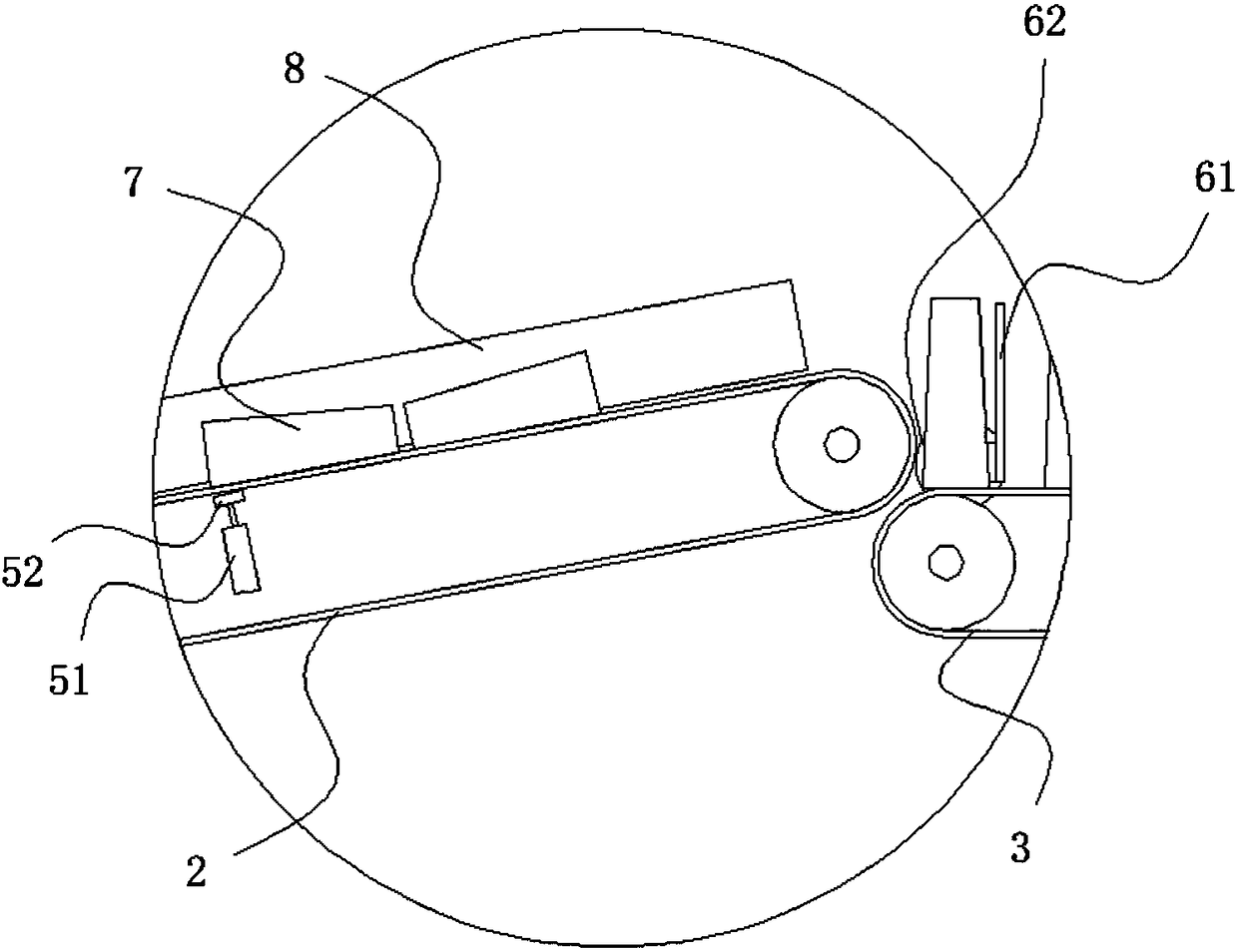

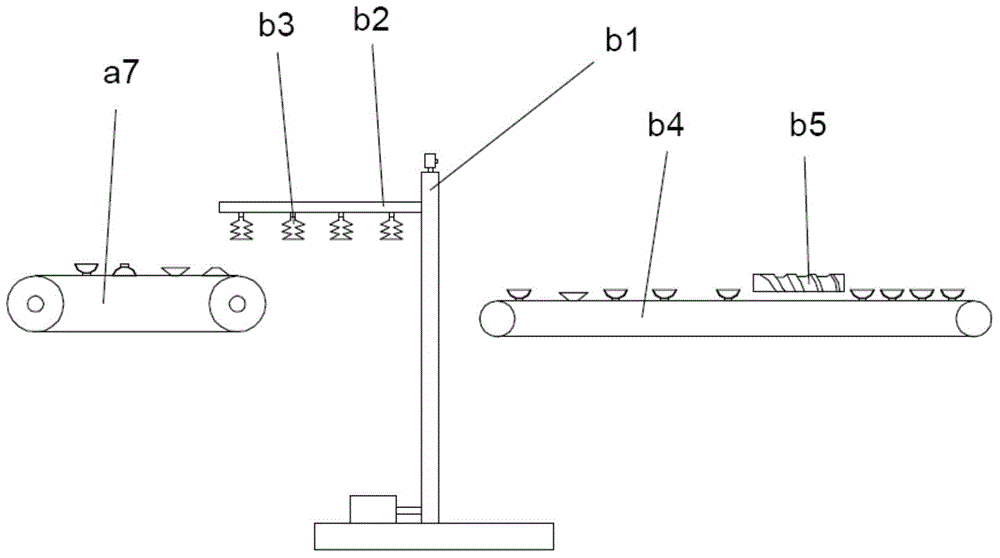

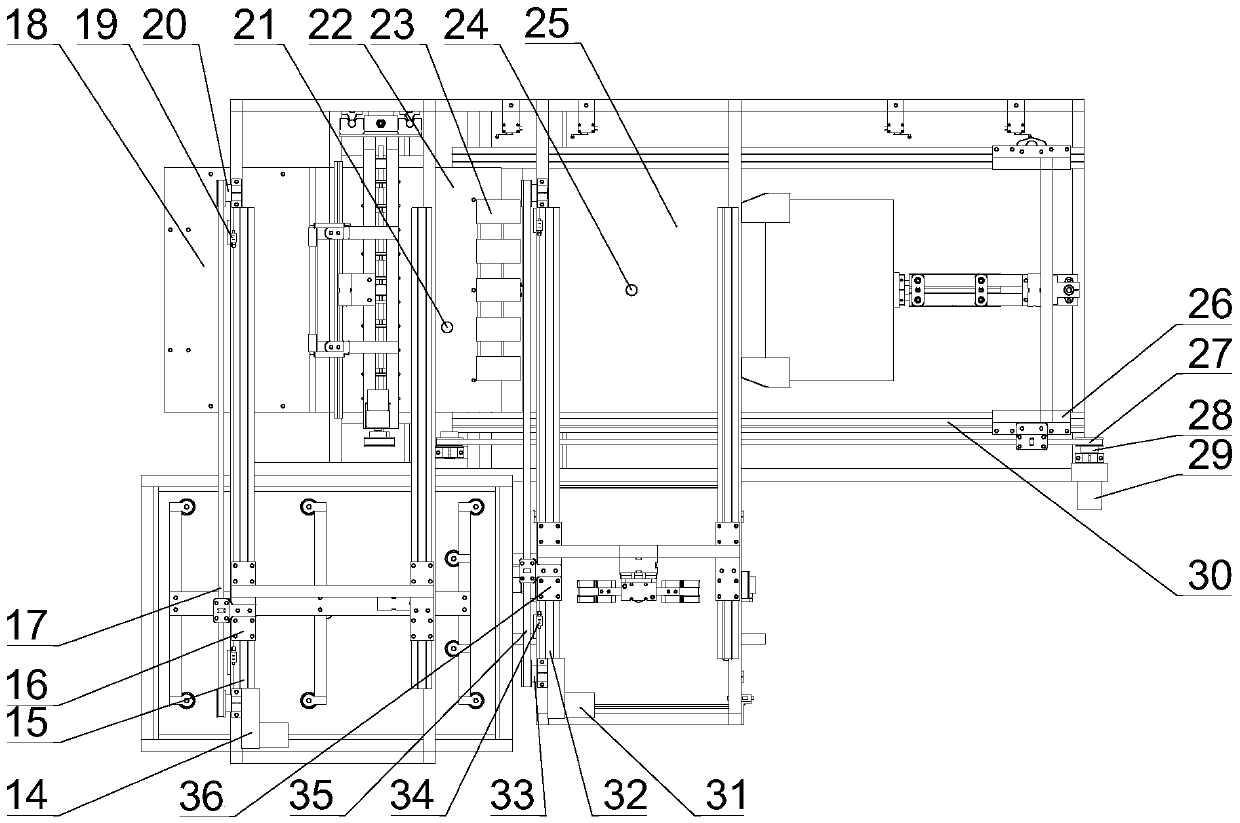

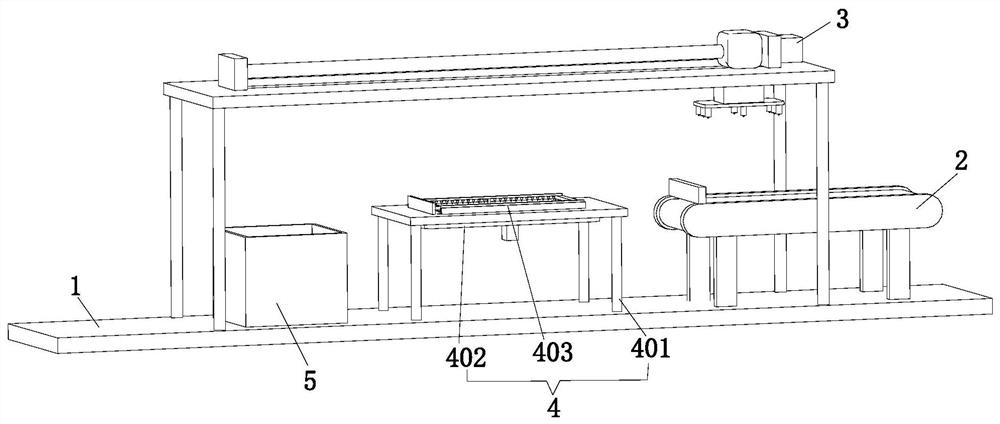

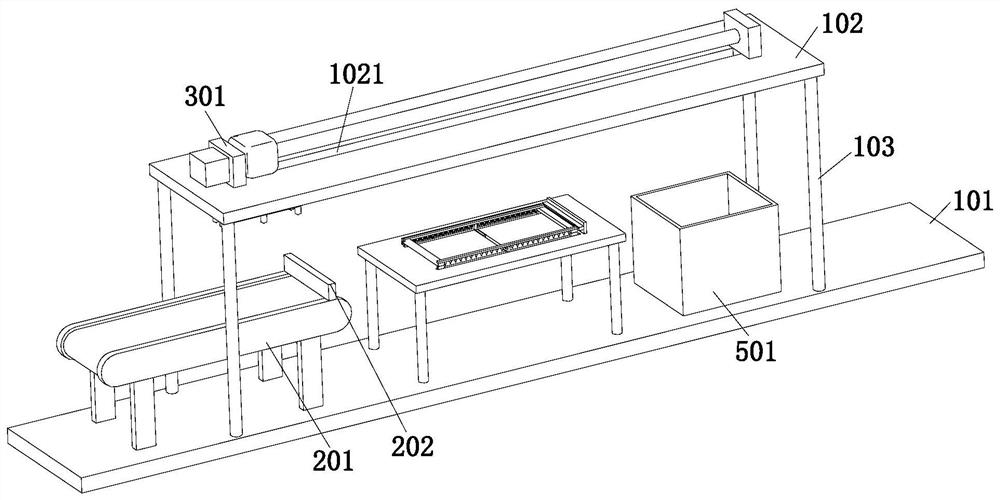

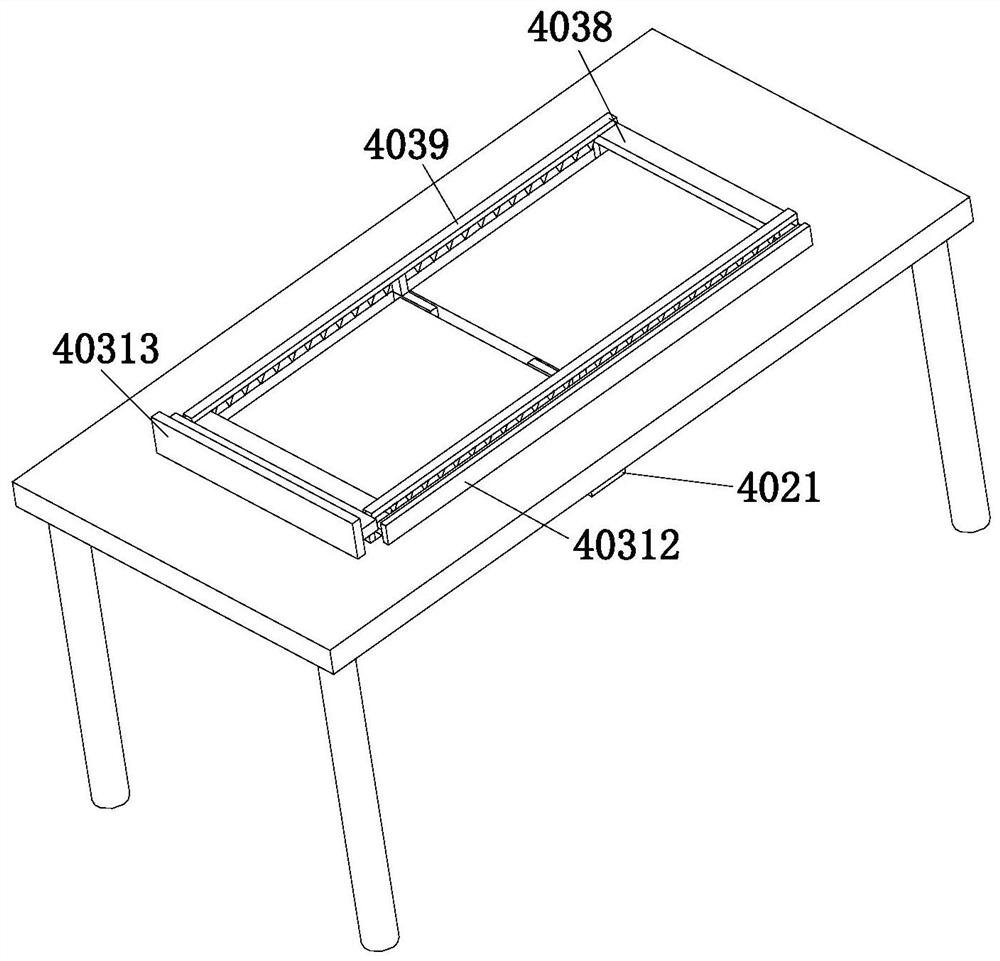

Bulk bobbin yarn arranging device

PendingCN108408426ALabor savingReduce manufacturing costControl devices for conveyorsLoading/unloadingYarnEngineering

The invention provides a bulk bobbin yarn arranging device and belongs to the technical field of spinning equipment. The bulk bobbin yarn arranging device comprises a storage bin with a vibrating structure, a front-section conveying belt with a detection device and an adjusting device, a rear-section conveying belt connected with the front-section conveying belt, and a strengthening device arranged between the front-section conveying belt and the rear-section conveying belt. According to the bulk bobbin yarn arranging device, discharging is carried out through the vibrating storage bin, and incooperation with conveying of the front-section conveying belt and the rear-section conveying belt, bobbin yarn can be transported automatically; meanwhile, through arrangement of the detection device and the adjusting device, big ends and small ends of the bobbin yarn can be adjusted, the bobbin yarn is changed from the horizontal state to the vertical state through the straightening device, bobbin yarn arrangement uniformity and regularity are achieved, and subsequent procedure processing is facilitated; and meanwhile, full-automatic operation is achieved, more labor is saved, the production cost is lower, the efficiency is higher, the labor burden of operators is relieved, and long-term development of enterprises is facilitated.

Owner:NINGBO DAQIAN TEXTILE

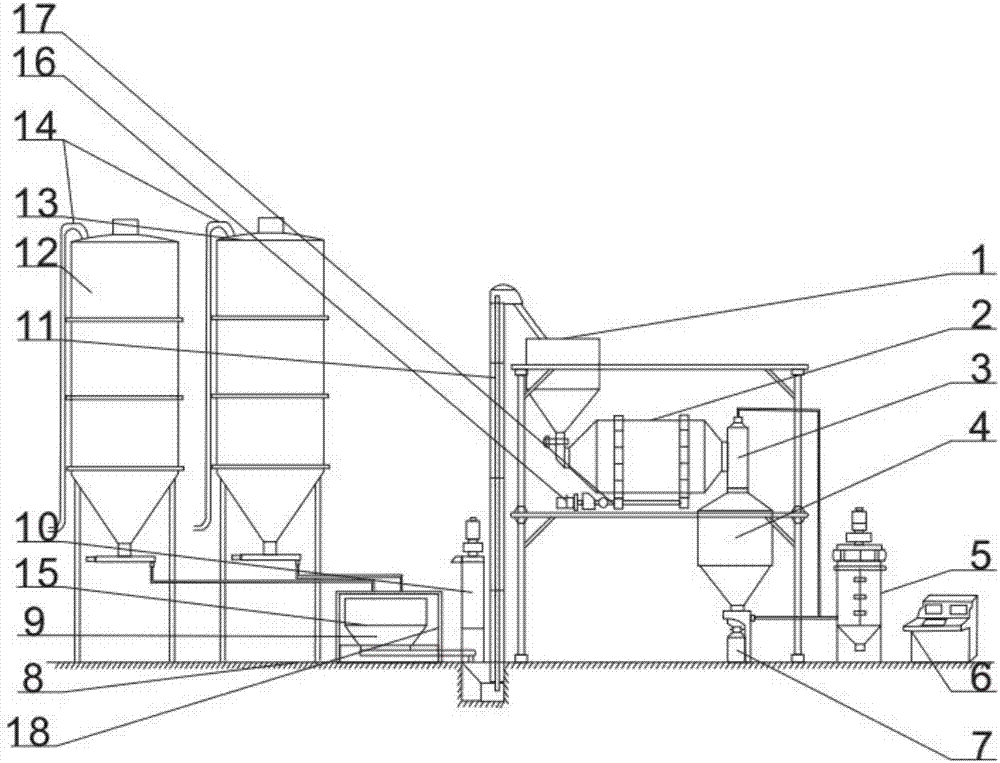

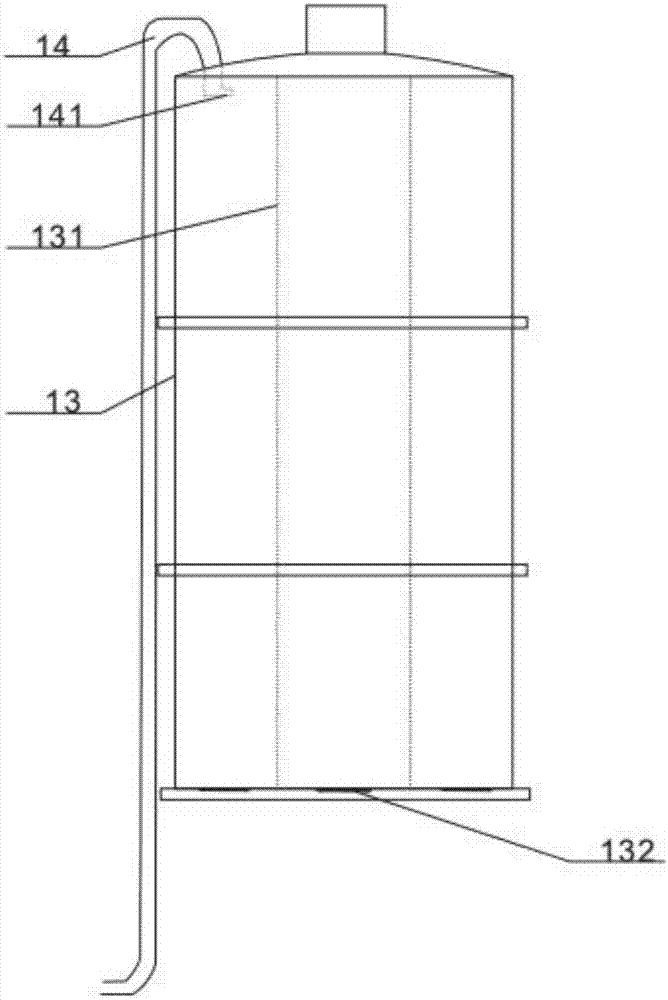

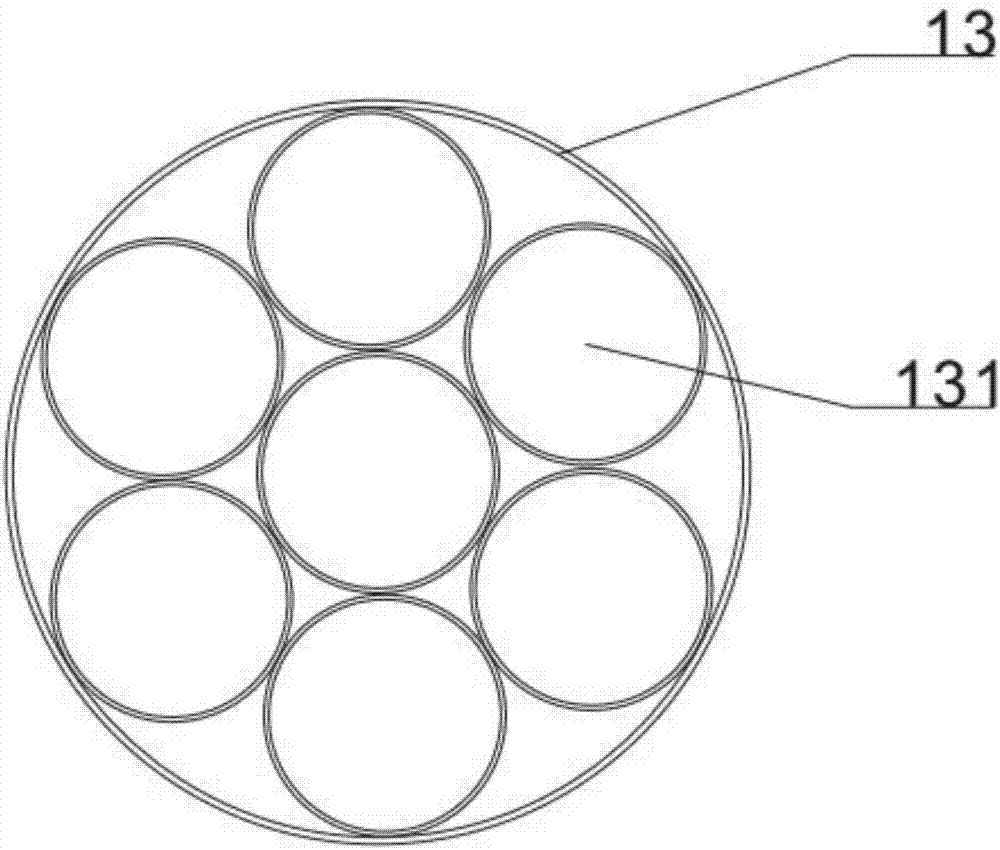

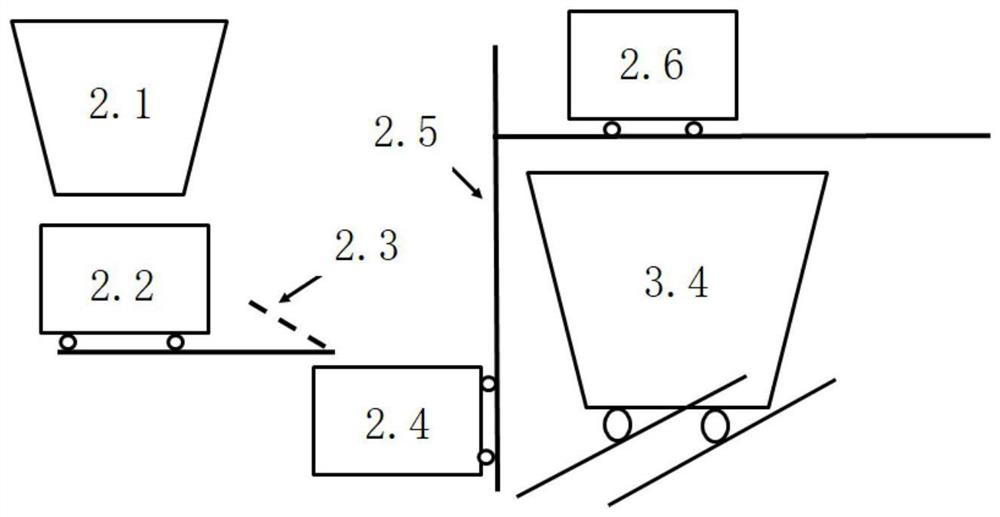

Full-automatic and multifunctional mortar production device

InactiveCN107263726AAchieve diversificationAvoid time costMixing operation control apparatusIngredients weighing apparatusThermal insulationProcess engineering

The invention provides a full-automatic and multifunctional mortar production device. The full-automatic and multifunctional mortar production device comprises a raw material bin, a hoisting machine device, a dust removal device, a finished product bin and a control cabinet and is characterized by further comprising an automatic weigh-batching hopper, a mixing waiting bin and a non-shaft rotary mixer; the raw material bin, the automatic weigh-batching hopper, the hoisting machine device, the dust removal device and the finished product bin are fixed on the ground; the raw material bin comprises a first raw material bin and a second raw material bin; each of the first raw material bin and the second raw material bin is connected with the automatic weigh-batching hopper; N small material bins are arranged in the second raw material bin; the automatic weigh-batching hopper is connected with the mixing waiting bin through the hoisting machine device; and the mixing waiting bin is connected with the non-shaft rotary mixer. According to the full-automatic and multifunctional mortar production device, the devices such as the first raw material bin, the second raw material bin, the automatic weigh-batching hopper, the mixing waiting bin and the control cabinet are arranged, so that the full-automatic working process is realized, the production cost is reduced, the production efficiency is improved, both ordinary mortar and thermal insulation glazed hollow bead mortar are produced simultaneously, and the product diversification is realized.

Owner:NANTONG HAIGAO CNC MACHINERY CO LTD

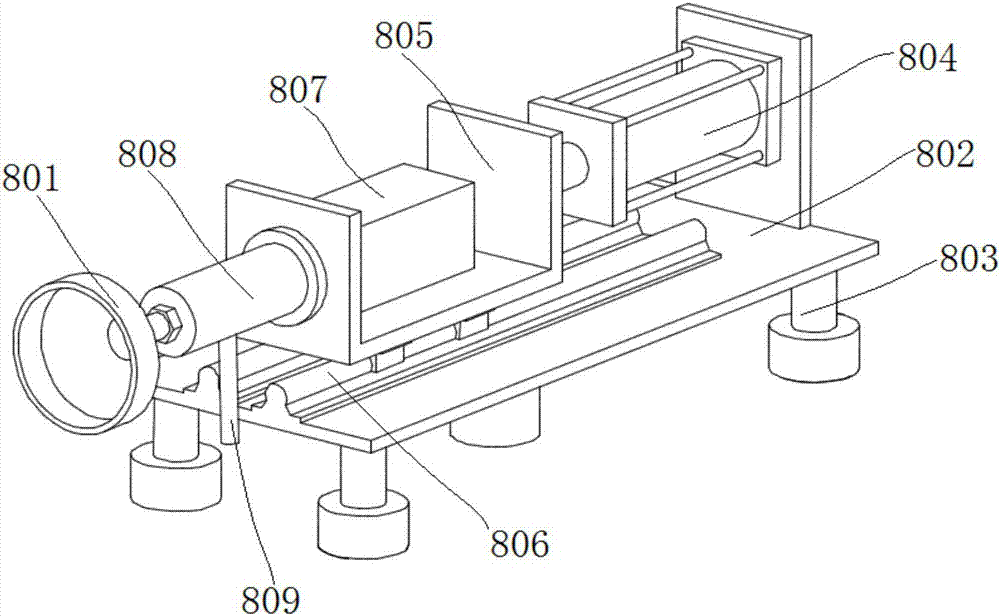

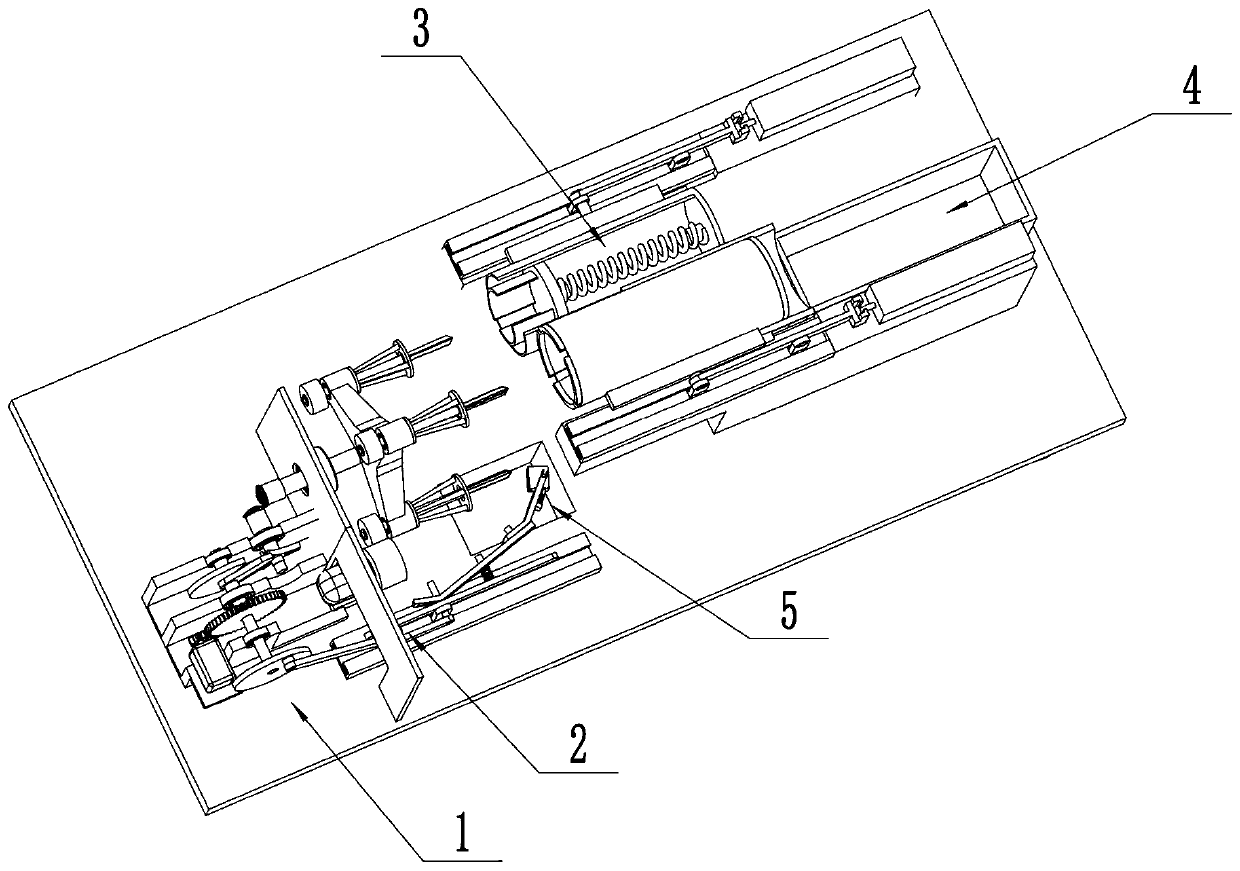

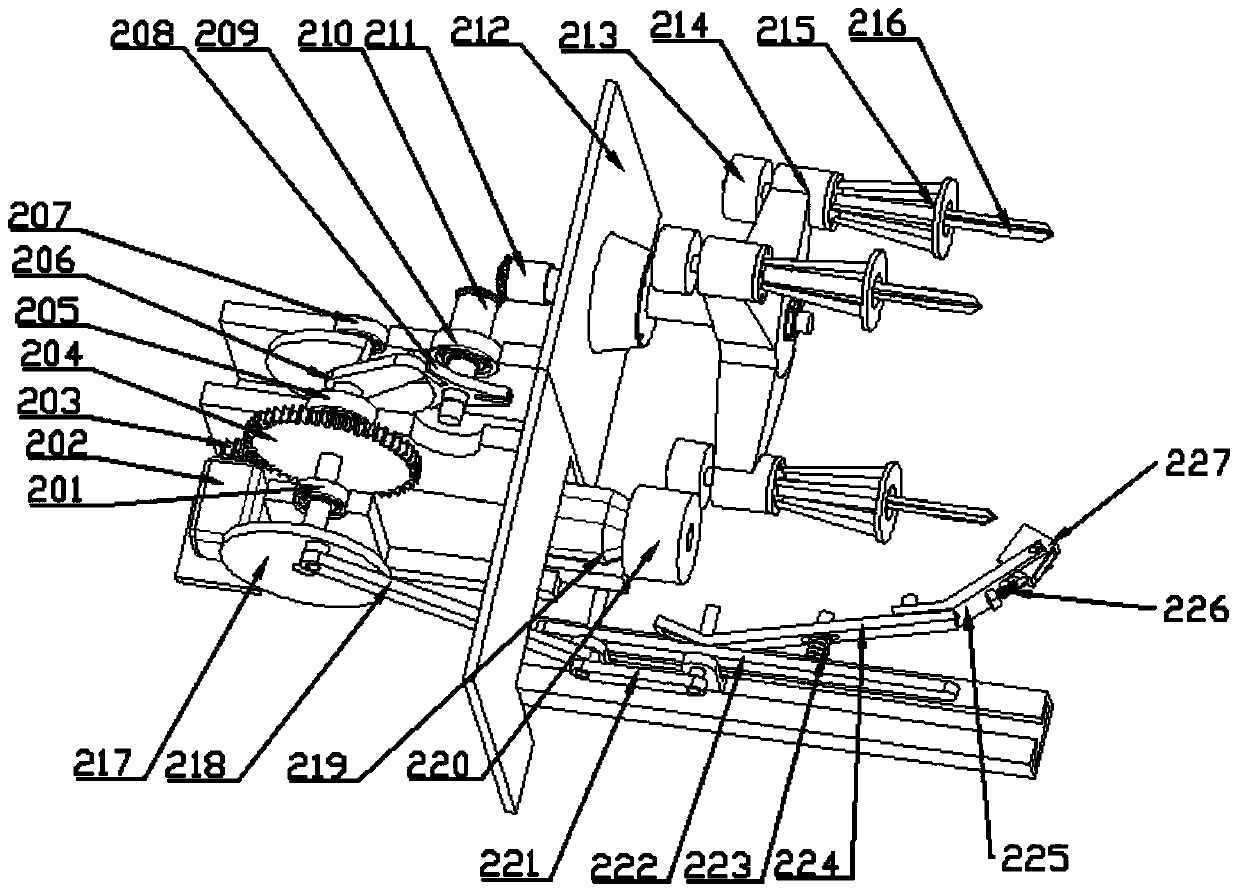

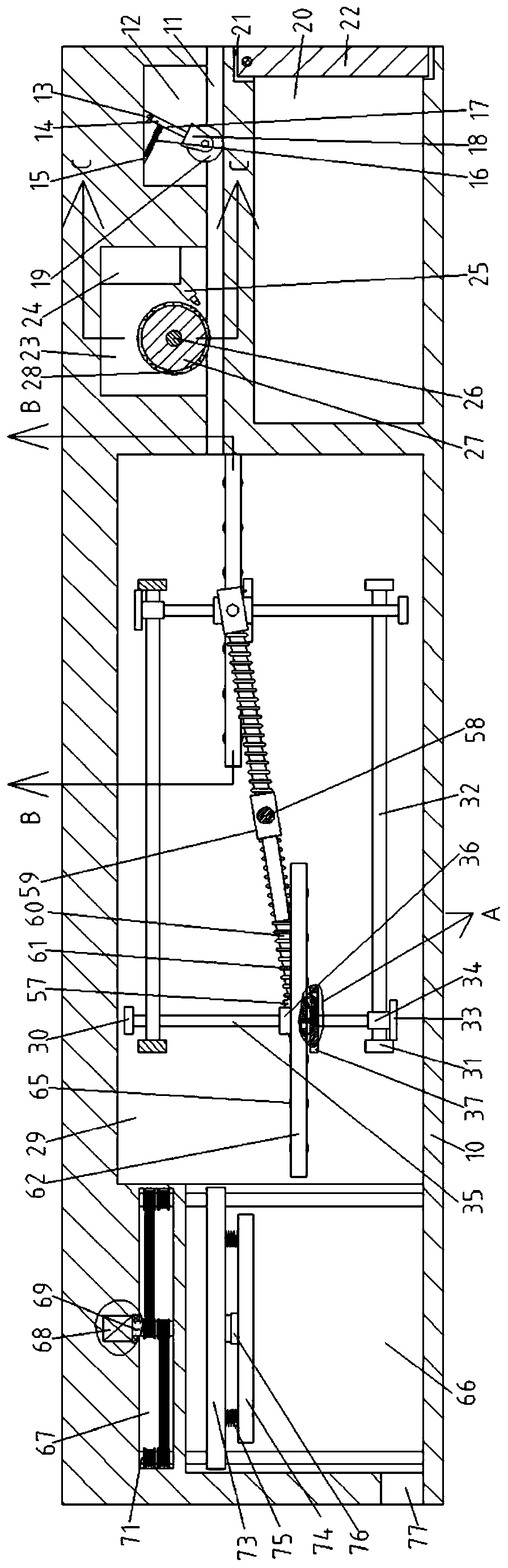

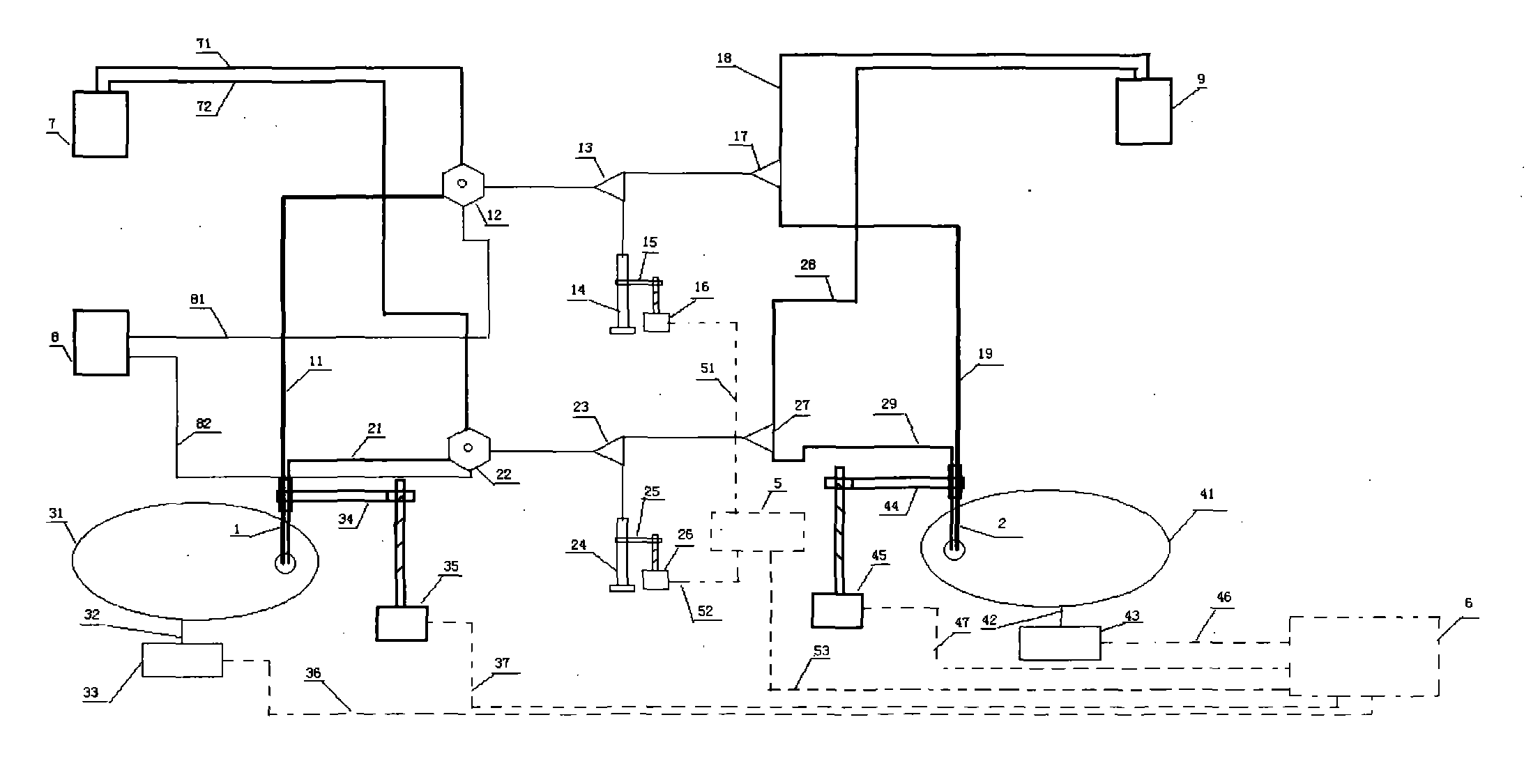

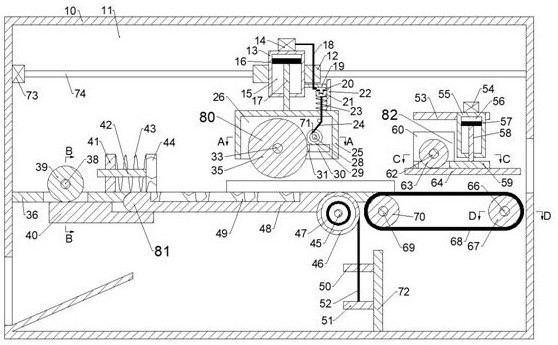

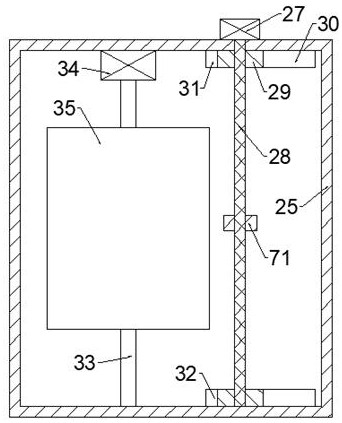

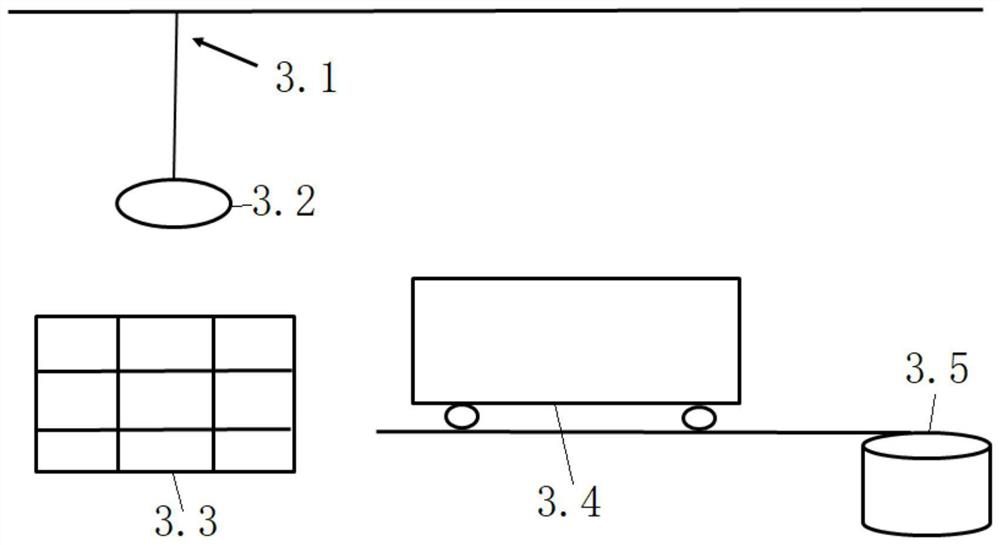

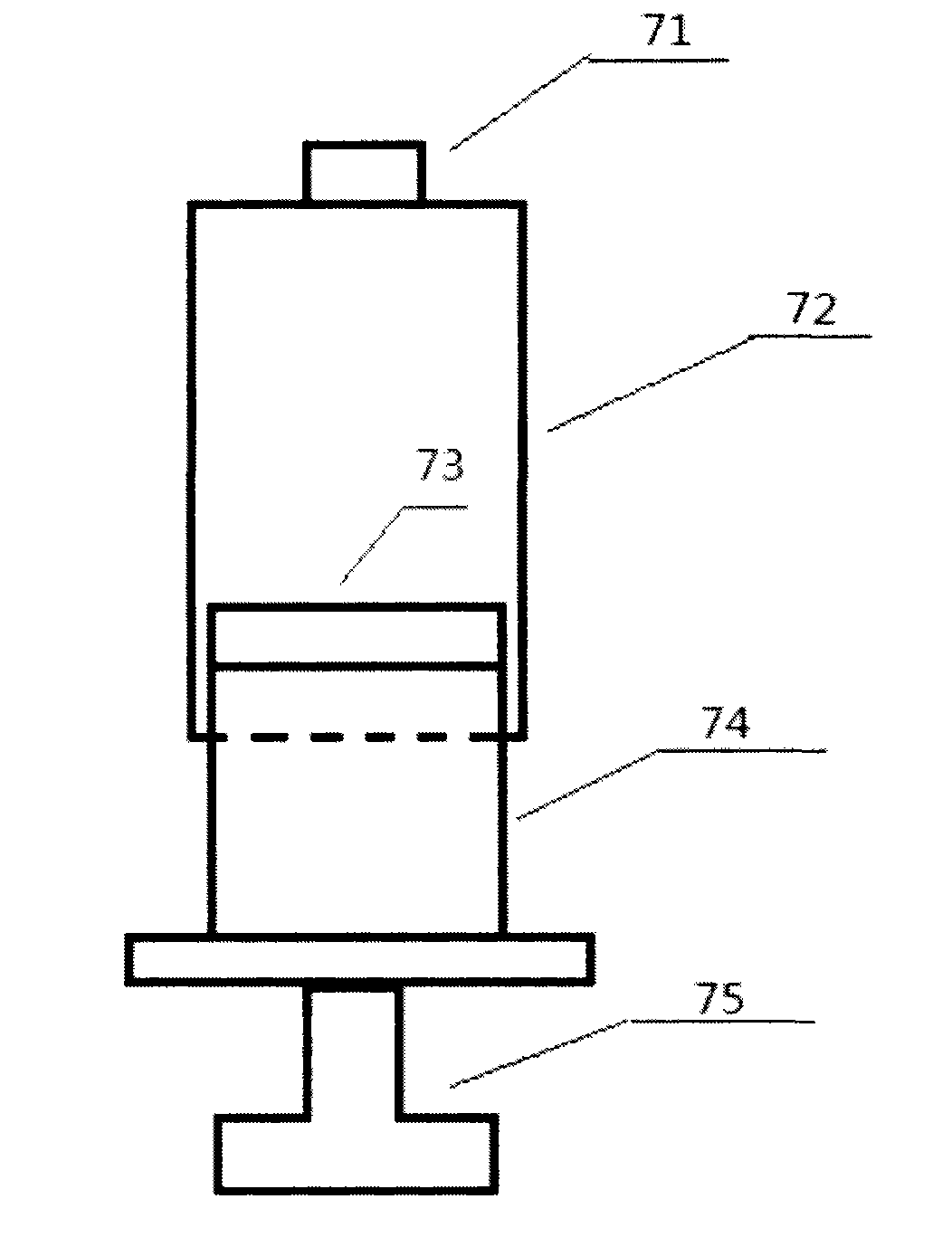

Full-automatic diluting instrument

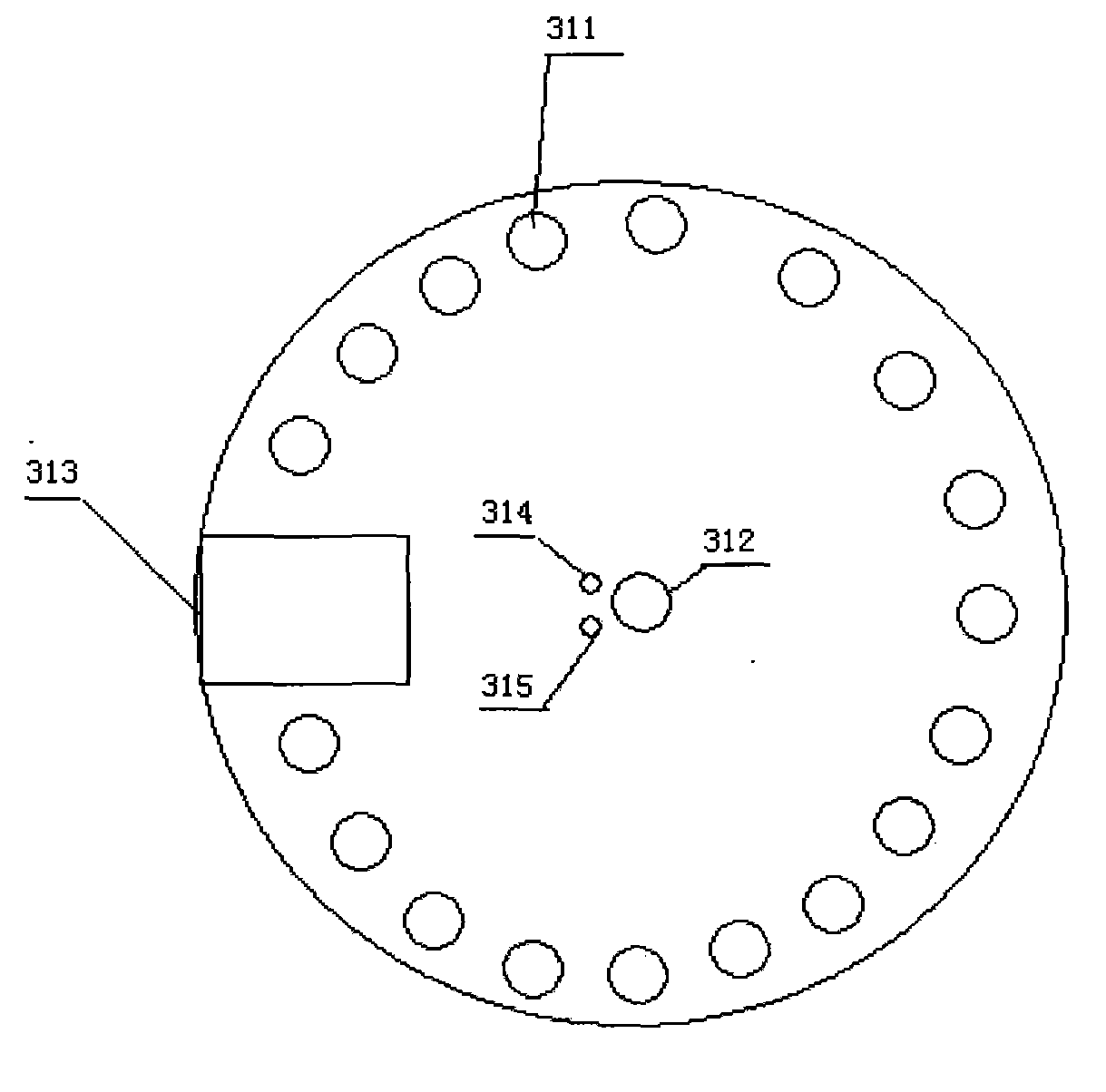

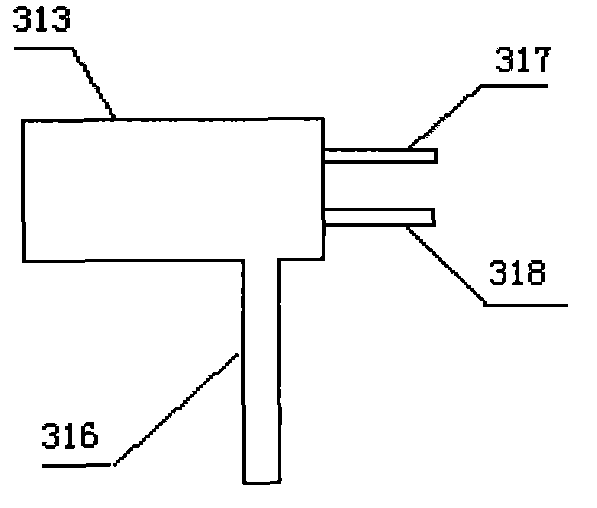

InactiveCN103884572ATo achieve the purpose of switchingWork the same wayPreparing sample for investigationDiluentEngineering

The invention relates to a full-automatic diluting instrument which can absorb a diluent automatically from a diluent channel, suck samples from a sample rotating disc one by one as a mother liquid, and injects and mixes the diluted liquids into corresponding tubes successively, thereby completing automatic diluting function of large-scale liquids. A system comprises dual-channel probes, multi-way injection valves, three-way valves, three-way or multi-way sample-separating valves, micro injectors, injector drive arms, probe drive arms, sample rotating disks, rotating disk bearings, rotating motors, a diluent container, a gas container, a waste liquid barrel, corresponding gas or liquid channels, a scheduling controller and a synchronous controller. The full-automatic diluting instrument performs sampling work by synchronously rotating the sample disk and through the movement of the probes, achieves a large-scale diluting object by combining up and down movement of the micro injectors and open and close of various valves, and can be widely applied in chemistry, biotechnology or other analytical testing experiments.

Owner:韦石

Tableware-nonbreakable washing equipment

InactiveCN106140642AImprove cleanlinessReduce breakage rateTableware washing/rinsing machine detailsBristle carriersBristleEngineering

The invention discloses tableware-nonbreakable washing equipment. The washing equipment comprises a sorting device, a dish steering arranging device and a dish washing device. The sorting device comprises a tableware collection bucket of which the bottom is provided with pulleys. A buffer support plate made of elastic materials is arranged on the joint of a fixed plate and a first conveying belt. The first conveying belt used for receiving tableware poured out from the tableware collection bucket is arranged on the side, far away from a clasping clamp, of the fixed plate. According to the dish steering arranging device, a transferring arm is provided with a plurality of transferring suction cups, and an arranging conveying belt is provided with a ranking screw used for ranking dishes. According to the dish washing device, a brush head frame is provided with a plurality of inner brush heads used for washing the inner wall of the tableware, outer brush heads are provided with outer wall brush bristles, and nozzles used for spraying washing liquid are arranged between adjacent outer brush heads. The tableware-nonbreakable washing equipment is simple in structure, full-automatic work of tableware sorting, arranging and washing procedures is achieved, the work efficiency is improved, and the labor intensity is relieved.

Owner:苏州旋特自动化科技有限公司

Grinding device capable of automatically adjusting distance according to abrasion degree of grinding wheel

InactiveCN112548778AAffect the factory qualityFully automated workGrinding drivesGrinding feed controlWheel wearMachine

The invention discloses a grinding device capable of automatically adjusting the distance according to the abrasion degree of a grinding wheel. The grinding device comprises a machine body, and a storage cavity is formed in the machine body. A grinding device body is arranged in the storage cavity, and the grinding device body comprises a first sliding block arranged between the inner walls of thefront side and the rear side of the storage cavity in a sliding mode. A first air pressure machine shell is fixedly arranged on the first sliding block. And the first air pressure machine shell penetrates through the upper end face and the lower end face of the first sliding block, a first air pressure machine is fixedly arranged on the upper end face of the first air pressure machine shell, andan air pressure cavity is formed in the first air pressure machine shell. According to the grinding device, the abrasion degree of the grinding wheel can be detected through a light generator and a light receiver arranged inside. Therefore, a push rod pushes a polishing box to move downwards so as to supplement the grinding distance, and the situation that the delivery quality is affected due to thickness inconsistency of metal plates is avoided; and meanwhile, the metal plates are pushed to proper positions through a top plate during feeding, a rotating plate rotates to be unloaded by means of the gravity of the metal plates after grinding is completed, and automatic work is achieved in the whole process.

Owner:南京利营池商贸有限公司

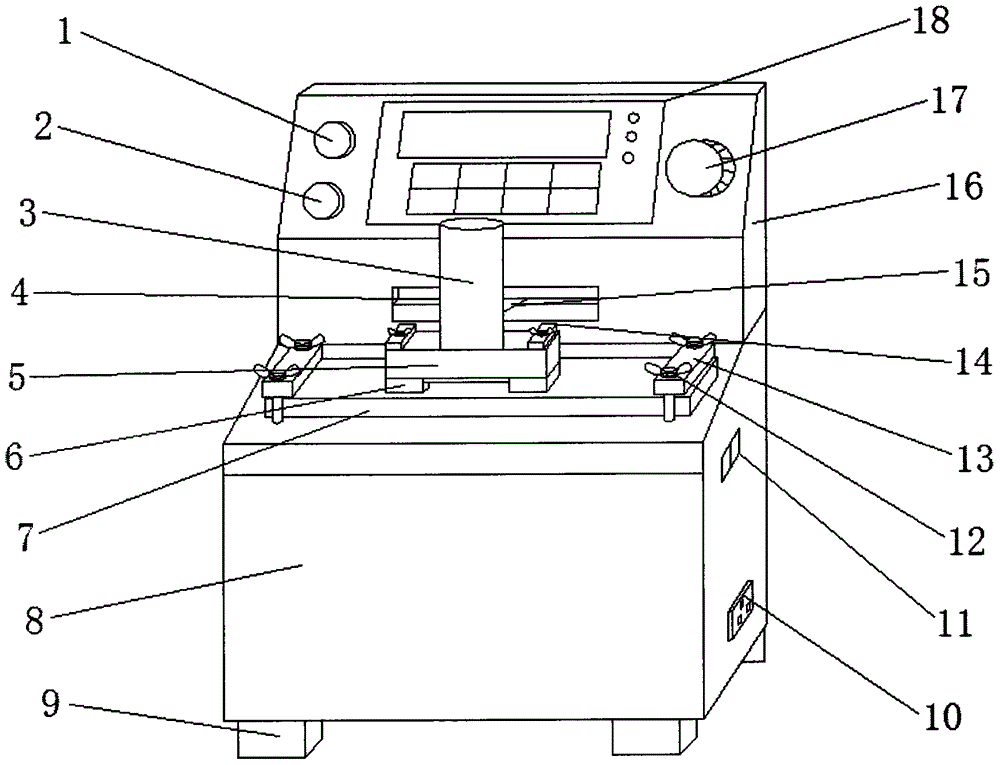

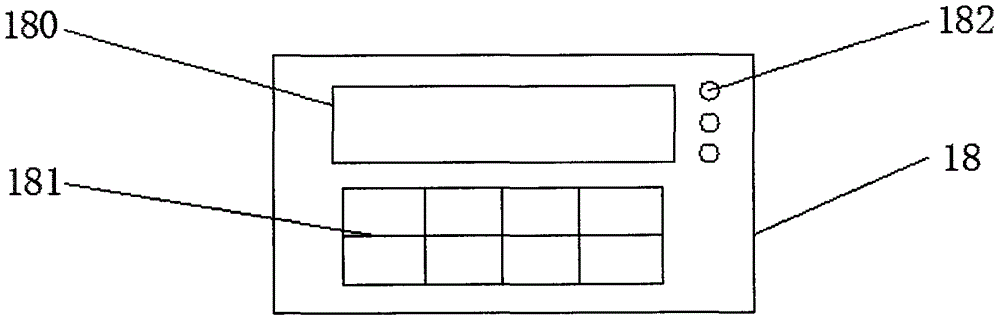

Full-automatic printing ink antifriction decolorization testing machine

InactiveCN106596399AEasy to operateReasonable structureUsing mechanical meansMaterial analysisLiquid-crystal displayPower switching

The invention discloses a full-automatic printing ink antifriction decolorization testing machine. The testing machine comprises a starting button, weights, an upper friction platform, a lower friction platform, a machine body, a power switch, pressure plates, a control console and a control panel. The control console is mounted above the machine body, the lower friction platform is mounted below a friction part which is mounted below the upper friction platform, and the pressure plates are fixedly mounted above the lower friction platform through butterfly bolts. A power interface is mounted below the power switch, supports are mounted below the machine body, and a horizontal slide device and the control panel are both electrically connected with the power switch. By microcomputer control, LCD (liquid crystal display) dynamic display and a thin-film inching operation panel, a power-cut memory function is achieved, and problems of poor abrasion resistance, low friction resistance, proneness to shedding and the like of ink layers of printing products are solved. In addition, the testing machine has advantages of simplicity in operation, structural reasonability, full automation in operation, high intelligence and convenience.

Owner:余姚市智达教仪设备成套有限公司

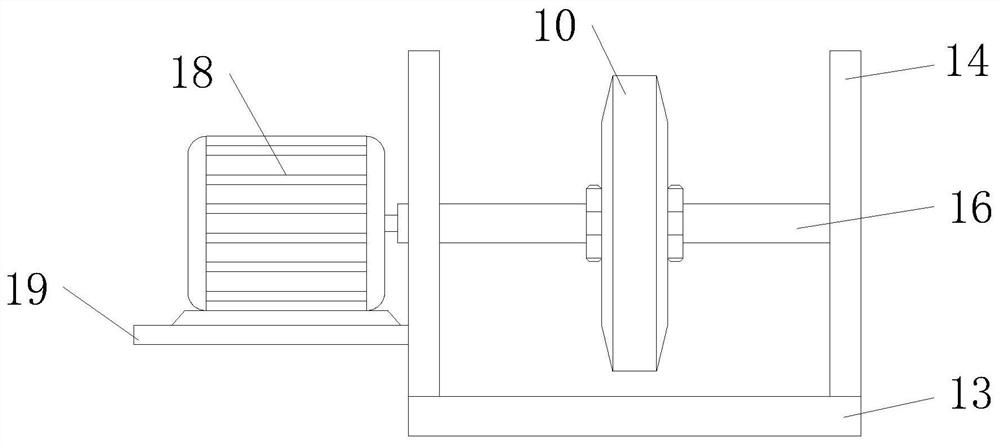

Cpp packaging film winding and storing device

ActiveCN113277353AImprove collection and storage efficiencyFully automated workWebs handlingElectric machineryEngineering

Owner:徐州宏恩包装新材料有限公司

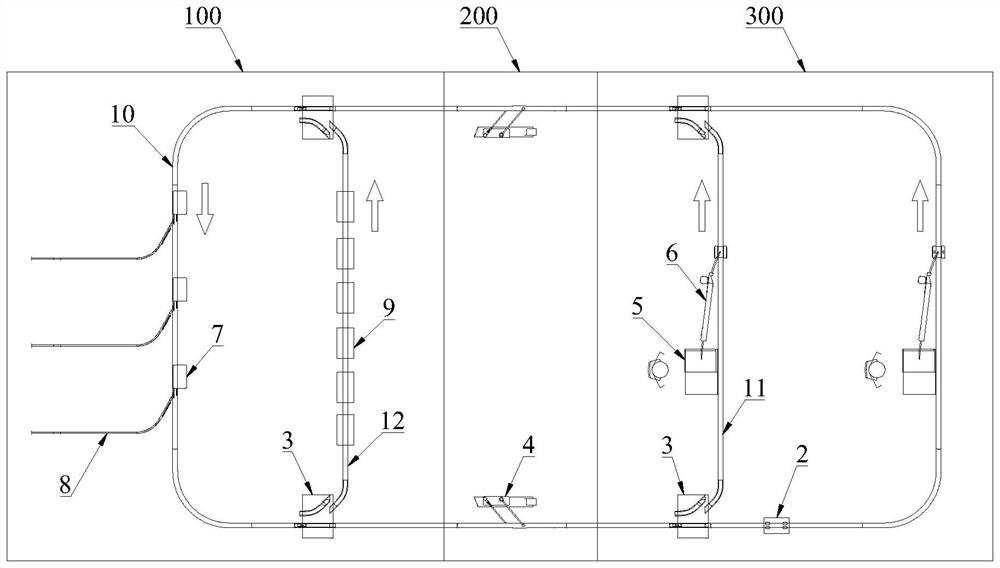

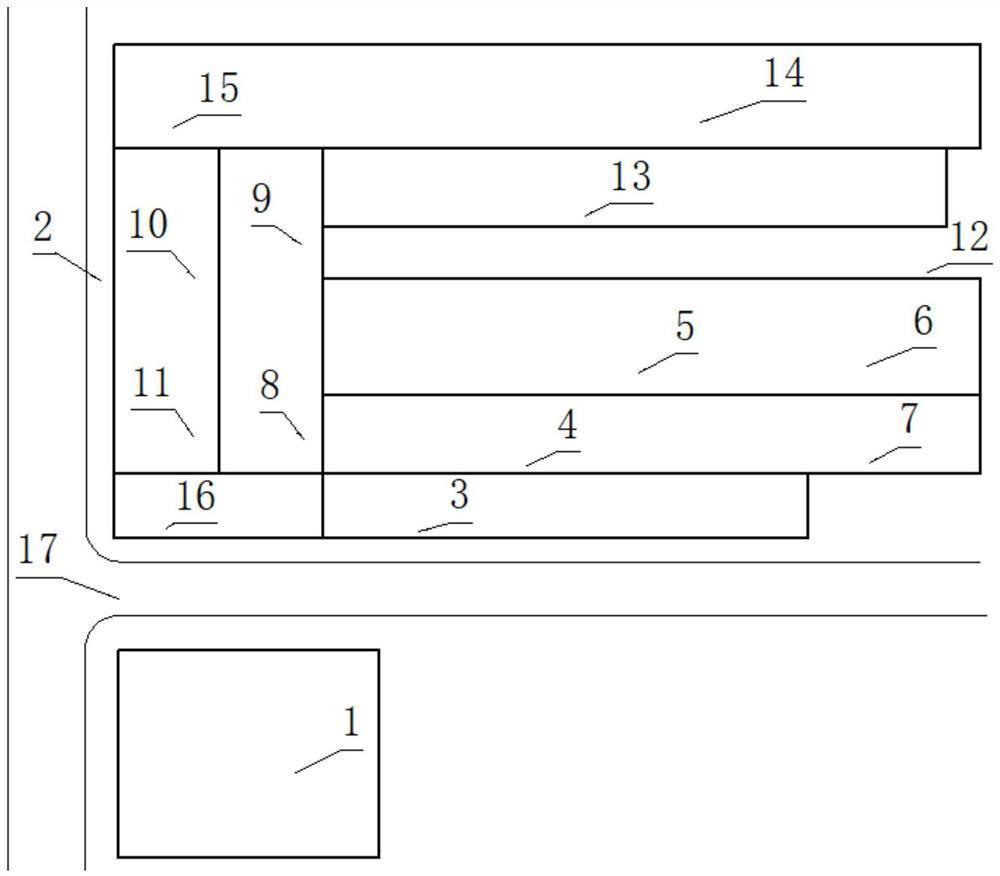

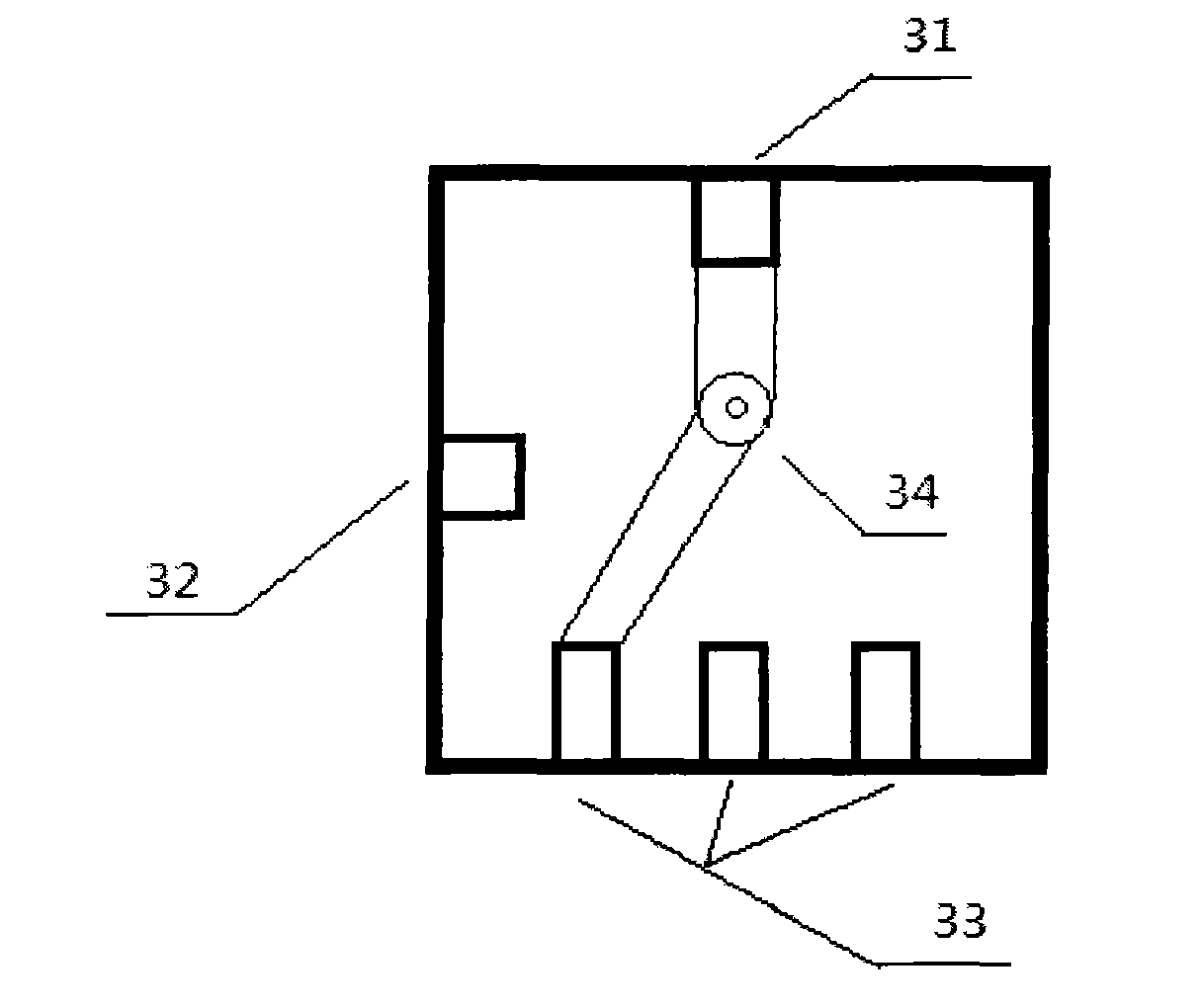

Configuration structure of full mold casting workshop

ActiveCN113909469ASave construction areaConstruction cost economyCasting plantsMould handling equipmentsFull-mold castingProcess engineering

The invention discloses a configuration structure of a full mold casting workshop. The configuration structure of the full mold casting workshop comprises a model making workshop and a casting workshop; the model making workshop is arranged on the south side of the casting workshop; the model making workshop and the casting workshop are provided with factory area internal roads arranged in the east-west direction; and the casting workshop comprises a flow coating and drying procedure area, a molding procedure area, a heat preservation procedure area, a shakeout procedure area, a sand regeneration procedure area, a pouring procedure area, a melting procedure area, a raw material warehouse area, a maintenance complete area, an equipment cross area, a cleaning and paint spraying procedure area, a machining procedure area and a finished product warehouse area. The configuration structure of the full mold casting workshop has the advantages of being small in building area, economical in construction cost and low in equipment configuration cost, the requirements of product production are met, and meanwhile the material flow is more optimized.

Owner:东风汽车零部件集团有限公司通用铸锻分公司

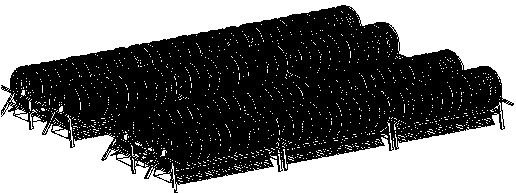

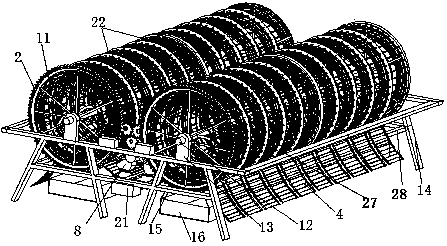

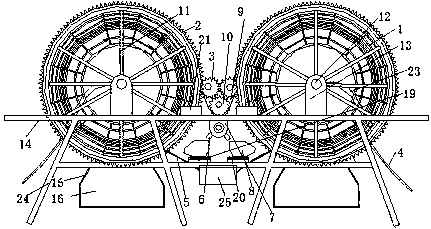

Suspended automatic feed excrement discharging environment-friendly pig cage

InactiveCN107683772APollution did not causePollution emissions did not causeFrom muscle energyAnimal feeding devicesEnvironmental engineeringHigh pressure gas

The invention discloses a suspended automatic feed excrement discharging environment-friendly pig cage which comprises two groups of pig cages, a gas pipe brushing structure, a supporting frame and anexcrement discharging device. A plurality of cylindrical pig cages are arranged on each group of pig cages, a cage inlet door is arranged at a 45-degree position of the inclined lower end of each cylindrical pig cage, a feeding door is arranged on a side symmetric with each cage inlet door, the cage inlet doors and the feeding doors are arc doors, the radian of the cage inlet doors and the feeding doors is as same as that of the cylindrical pig cages, the cage inlet doors are opened from inside, from top to bottom and outwards, the feeding doors are opened from inside, from bottom to top andoutwards, and hollow shafts are arranged in the middles of the cylindrical pig cages. The cylindrical pig cages with mesh structures are brushed by the gas pipe brushing structure, high-pressure gas is matched with a small amount of water, brushed excrement is discharged into an excrement discharging structure and then conveyed into a methane tank, pollution-free discharging is realized, and full-automatic operation can be realized.

Owner:柳春泰

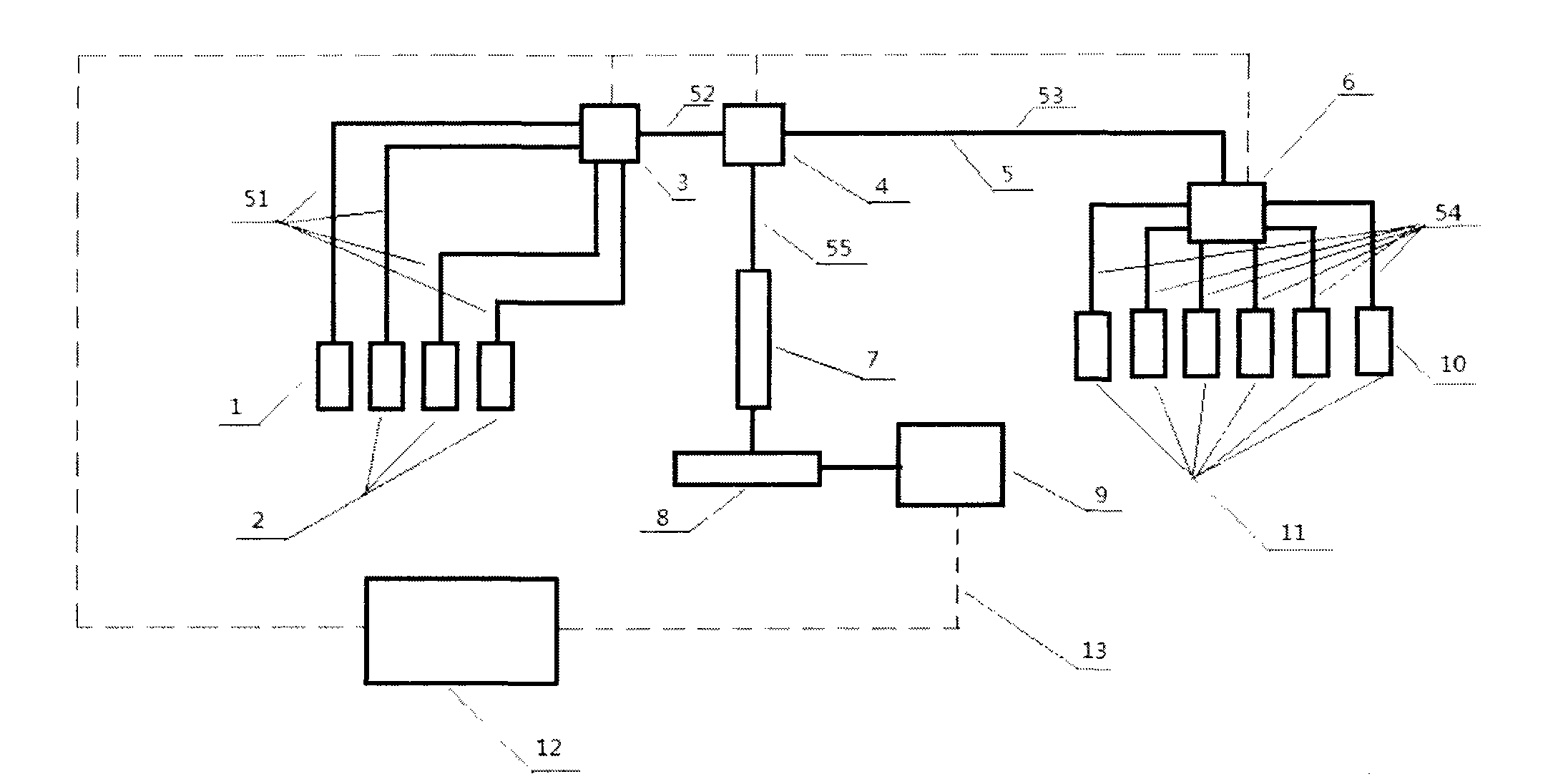

Automatic liquid adsorption and distribution system of single microsyringe

InactiveCN102735862ARealize free combinationAvoid the tedious work of manual cleaningMaterial analysisControl lineDistribution system

An automatic liquid adsorption and distribution system of a single microsyringe is characterized by complicated functions of freely combing liquid adsorption channels and liquid distribution channels, automatically adsorbing a plurality of liquids by the single microsyringe, and distributing the liquids to different containers. The automatic liquid adsorption and distribution system includes a cleaning liquid container, to-be-distributed liquid containers, a multi-channel liquid absorption electromagnetic selector valve, a double-channel electromagnetic valve, a liquid master channel, a multi-channel liquid distribution electromagnetic selector valve, the microsyringe, a microsyringe drive arm, a precise stepping motor, a waste liquid container, distributed liquid containers, a controller and control lines. The automatic liquid adsorption and distribution system can switch the electromagnetic valve to select the required liquid channel, and realize the liquid adsorption and distribution function through the up and down movement of the piston of the microsyringe, and can be widely applied to chemistry, biology and other analysis and test experiments.

Owner:韦石

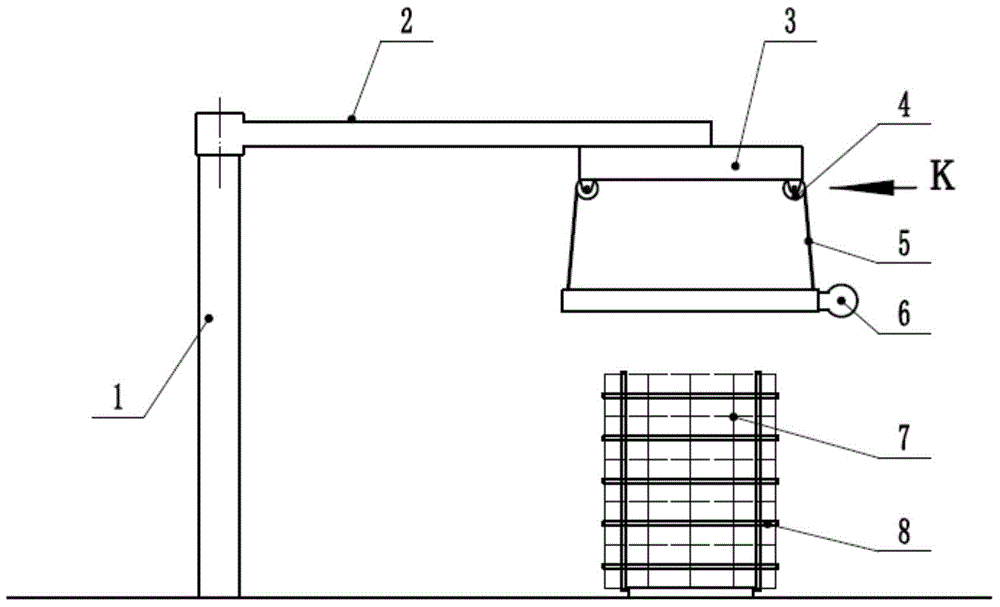

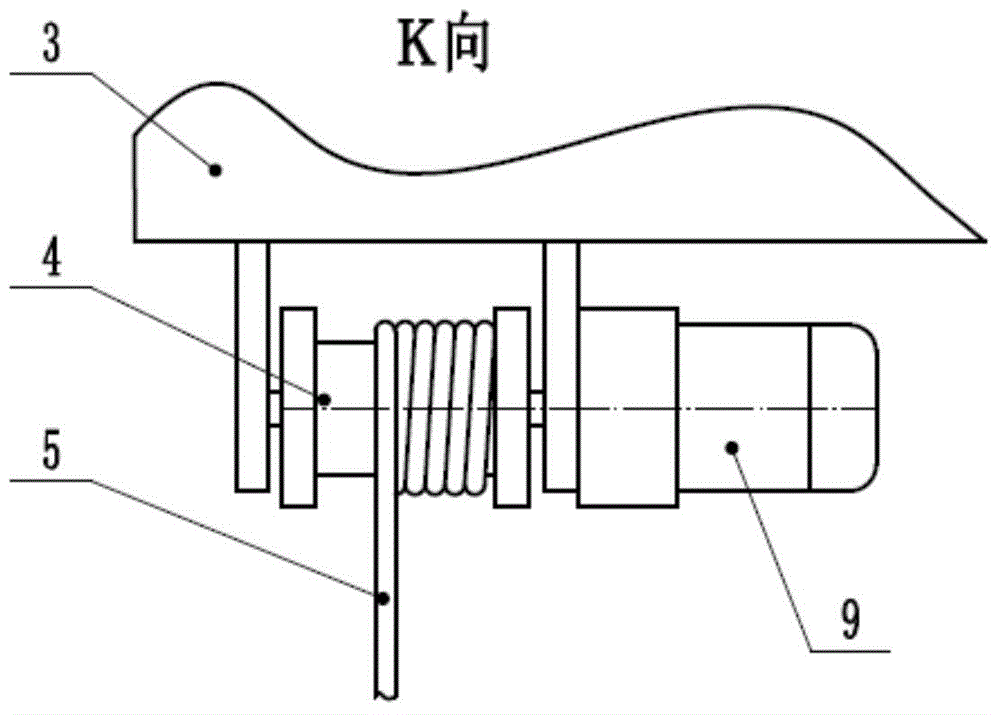

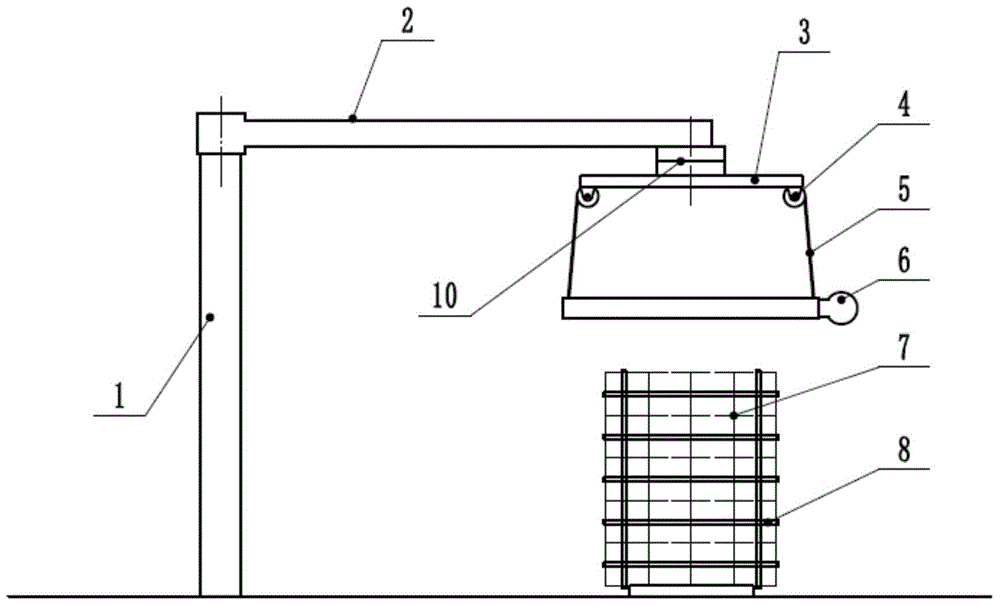

Binding packer

InactiveCN106143981ARealize automatic followAchieve liftingBinding material applicationBundling machine detailsManual tractionMechanical engineering

The invention provides a binding packer. The binding packer comprises a packer head unit, a top base positioned on the upper side of the packer head unit and capable of moving, and a set of lifting ropes for connecting the top base with the packer head unit; and the packer head unit is hung below the top base through the lifting ropes. The packer head unit can be horizontally operated above materials under manual traction or power driving, and is descended to a binding position of the materials through release of the lifting ropes; and finally, the packer head unit finishes automatic packing without carrying or flowing the materials, so that the labor intensity is reduced, and the working efficiency is improved.

Owner:范红兵

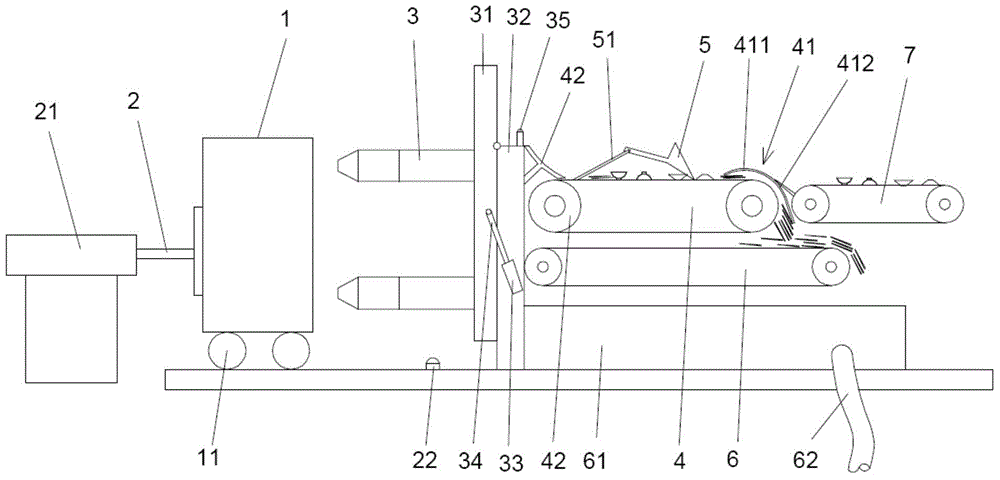

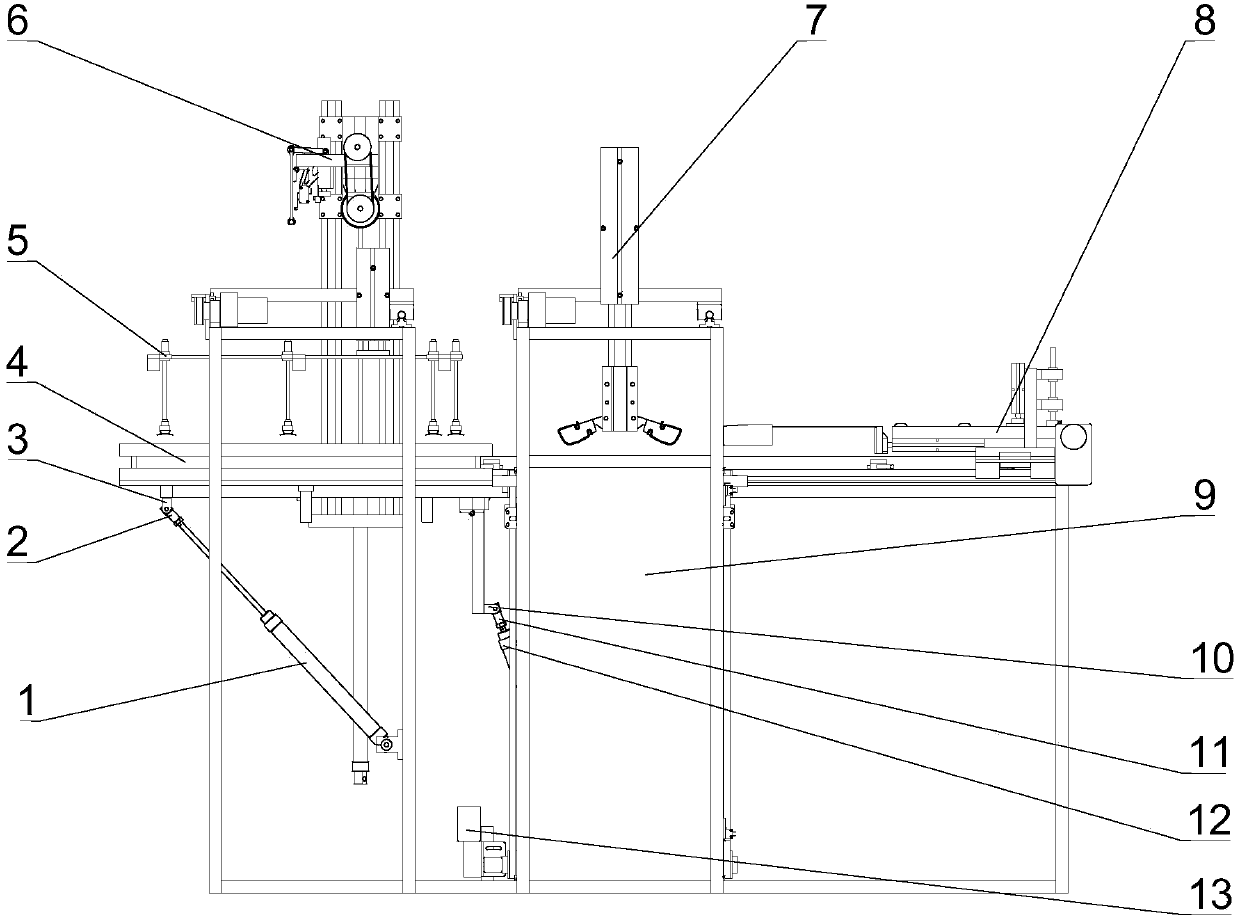

A fully automatic garment express bag packaging machine

ActiveCN105857704BSolve the shortage of human resourcesFully automated workWrapper twisting/gatheringPackaging machinesEngineeringE-commerce

The invention discloses a full-automatic clothing express bag packing machine. The full-automatic clothing express bag packing machine comprises a rack, a clothing hopper, a bag hopper, a bionic pneumatic claw mechanism, a bag taking suction cup mechanism, a moving component, a fan-shaped retaining clip component, a clothing pressing plate push type clothing loading mechanism and a roller type tightening heat sealing mechanism. According to the full-automatic clothing express bag packing machine, spring, summer and autumn clothing as well as thin winter clothing can be basically packed; the packing machine is controlled by a PLC, automation is achieved, and the packing tasks of large batches of clothing express bags can be independently completed; and the full-automatic clothing express bag packing machine aims at reducing the operating cost and improving the packing efficiency for clothing e-commerce operators, especially entrepreneurs.

Owner:HANGZHOU DIANZI UNIV

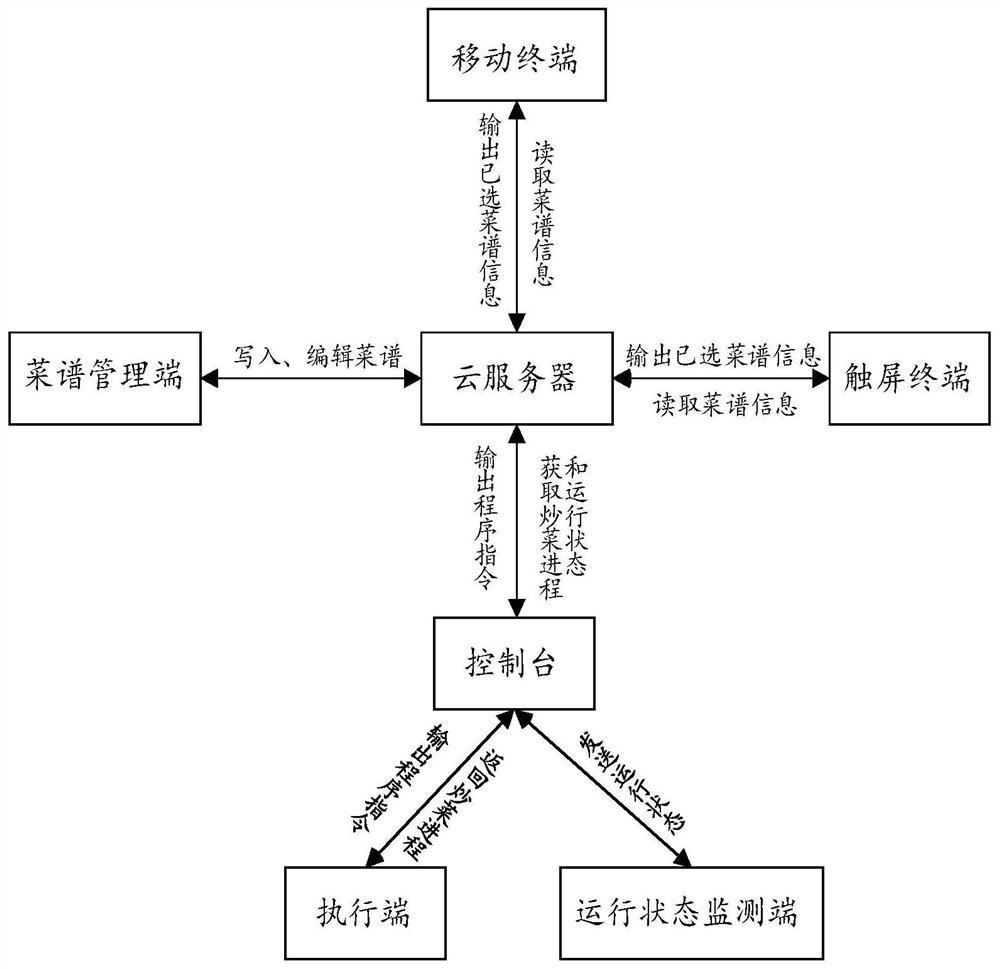

Double-end control system and method of intelligent cooker and cooker

InactiveCN113057499AFully automated workRealize remote controlTime-controlled ignitorsProgram instructionControl system

The invention belongs to the technical field of intelligent home control, and discloses a double-end control system and method of an intelligent cooker and the cooker. The system comprises a mobile terminal and a touch screen terminal which are used for reading a menu database of a cloud server, the cloud server which is used for generating a corresponding program instruction according to the at least one menu, sending the program instruction to a console, receiving cooking process information returned by the console and forwarding the cooking process information, the console which is used for receiving the program instruction and enabling the execution end to execute the corresponding cooking process according to the program instruction, and is used for receiving the cooking process information returned by the execution end, and the execution end which is used for executing the corresponding cooking process according to the program instruction and returning cooking process information to the console. By arranging the mobile terminal and the touch screen terminal, remote control over the cooker can be achieved, near-end control can be achieved, manual intervention is not needed in the whole process, and full-automatic work of the cooker is achieved.

Owner:徐光瑞

Adhesive paper equipment

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

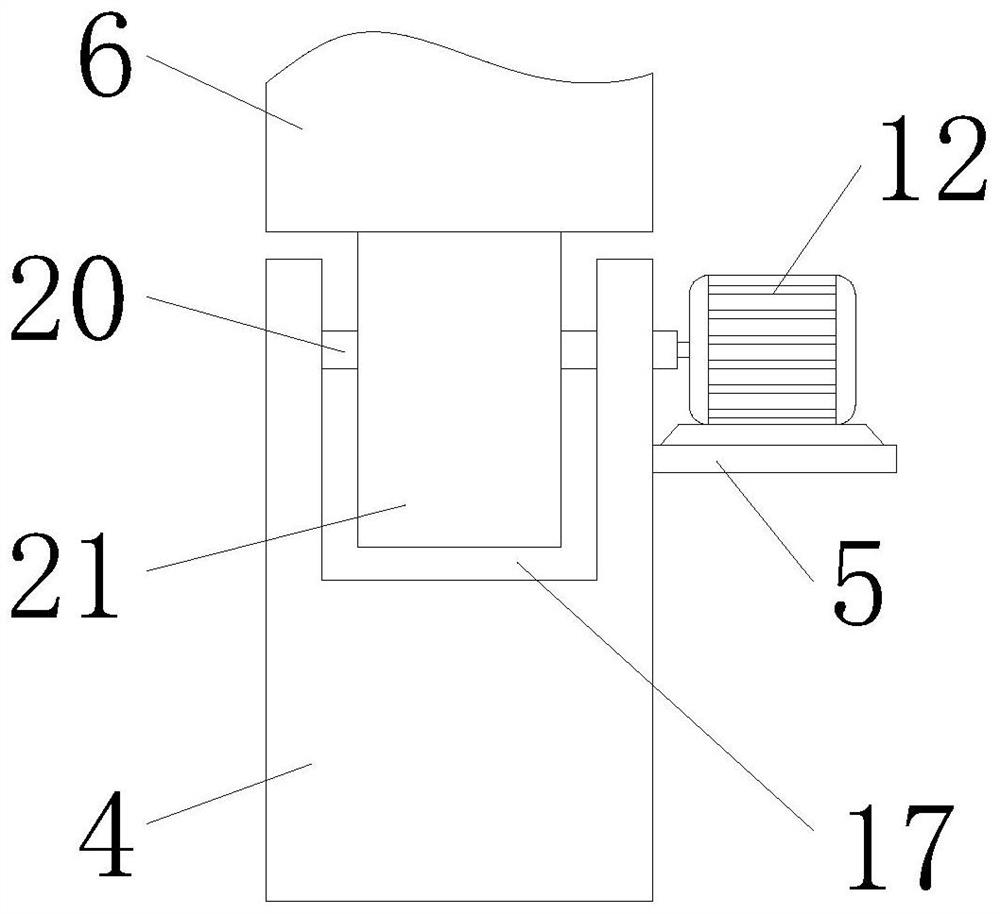

Gear maintaining device and method

PendingCN112452628AAchieve maintenanceFully automated workLiquid surface applicatorsCleaning using toolsGear wheelControl engineering

The invention provides a gear maintaining device and method, and relates to the technical field of gear maintaining. The gear maintaining device comprises a moving balance weight base; a control box is fixedly connected to any side of the upper surface of the moving balance weight base; a supporting moving column is arranged above the moving balance weight base; a rotating groove is formed in theupper surface of the supporting moving column; a second fixing placing plate is fixedly connected to the position, located at the rotating groove, of the outer wall of the supporting moving column; asecond driving motor is fixedly connected to the upper surface of the second fixing placing plate; a rotating shaft is fixedly connected to the driving end of the second driving motor; the side wall,away from the supporting moving column, of the rotating shaft is rotationally connected in a penetrating mode; and the side, away from the second driving motor, of the rotating groove is rotationallyconnected. According to the gear maintaining device and method, a to-be-maintained gear and a new gear can be cleaned and maintained conveniently, anti-rust oil is smeared, the service life of the gear is longer, maintenance is more convenient and faster, and the cost is low.

Owner:重庆优多齿轮制造有限公司

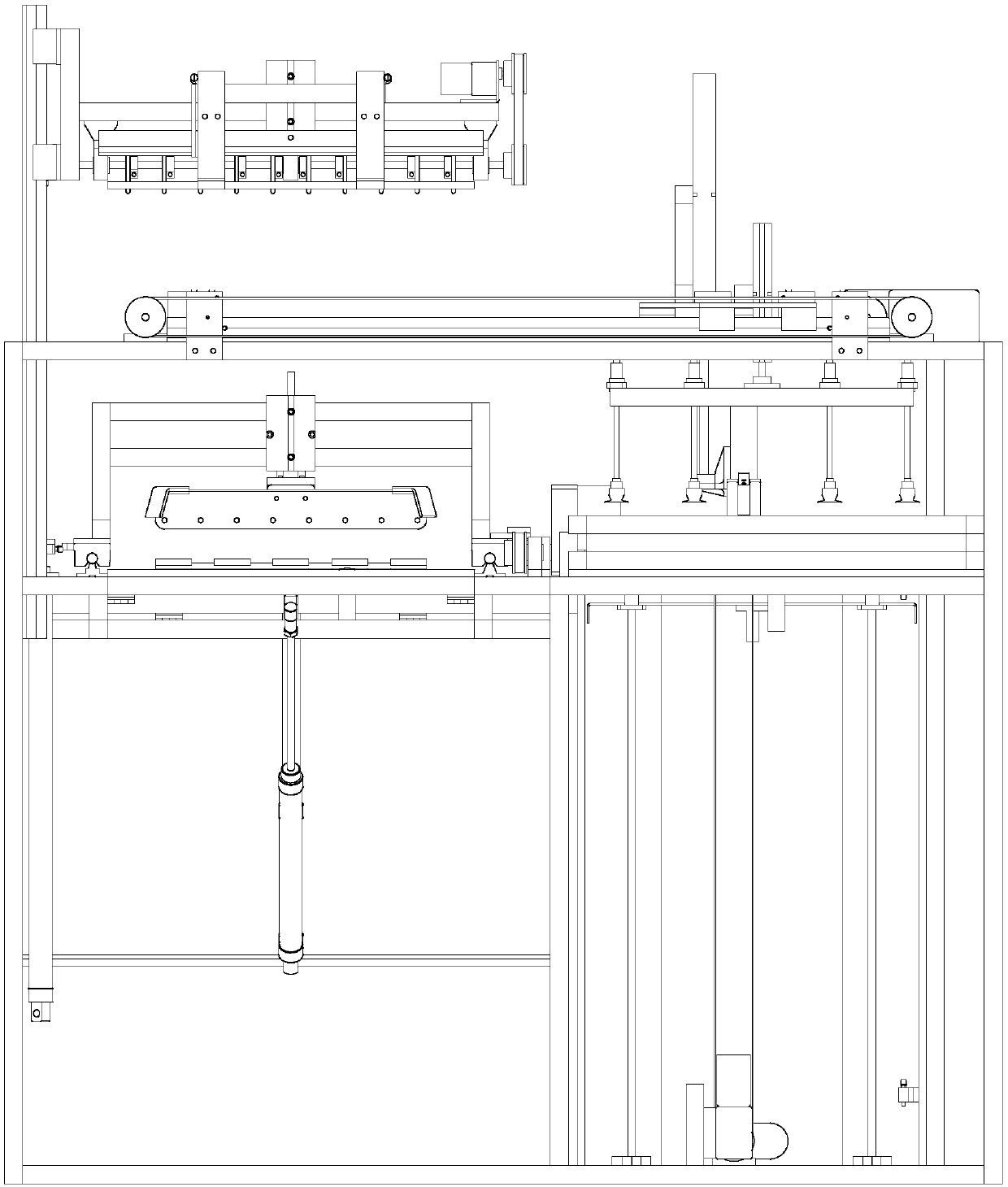

Automatic fur plate supporting process

InactiveCN111826479AEven by forceAvoid shapelessnessSkins/hides/leather/fur manufacturing apparatusElectric machineryIndustrial engineering

The invention belongs to the technical field of fur processing, and relates to an automatic fur plate supporting process. The automatic fur plate supporting process comprises the following steps that1, the fur to be shaped is automatically feed; 2, the fur to be shaped is transferred to a bearing plate; step 3, the fur is automatically stretched and fixed; and 4, automatic discharging is carriedout. The automatic fur plate supporting process is ingenious in design and smooth in procedure connection, the fur is stretched through movement of a motor, stress is uniform, the stroke and the advancing speed of the motor can be set according to the size and the specification of the fur, and therefore the tensioning degree of fur supporting is accurately controlled, it is guaranteed that the furcannot be too loose, and the situation that the fur cannot be shaped is avoided; and according to the fur plate supporting process, the situation that the fur is damaged or cracked due to excessive tightness, and consequently badness is caused is avoided, so that the fur plate supporting shaping efficiency can be greatly improved, the fur plate supporting shaping yield can be greatly increased, and the fur plate supporting process has remarkable economic value.

Owner:曾建林

A visual inspection method for disk-shaped suspension porcelain insulators

ActiveCN107179323BEasy to operateAccurate Defect DetectionOptically investigating flaws/contaminationEngineeringMechanical engineering

The invention discloses a visual detection method for a disc suspension type ceramic insulator. The method comprises the following steps: 1) establishing feature libraries of various defects; 2) confirming a numerical range of each type of defects in the feature library, and further refining the defects to establish a more detailed defect reference database to determine the type and specific state of a defect; 3) determining if a to-be-detected ceramic insulator is at a detection position; 4) performing image processing on collected image data; 5) utilizing a threshold segmentation principle to process and analyze the image processed and analyzed in the step 4), comparing the processing and analysis result with the defect reference database established in the step 2) one by one, if matching match is found, sending an unqualified signal of the ceramic insulator, and if not, sending a qualified signal of the ceramic insulator. The visual detection method is convenient in operation, is capable of greatly reducing labor intensity and increasing the detection working efficiency and is capable of accurately detecting the defects of the ceramic insulator.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

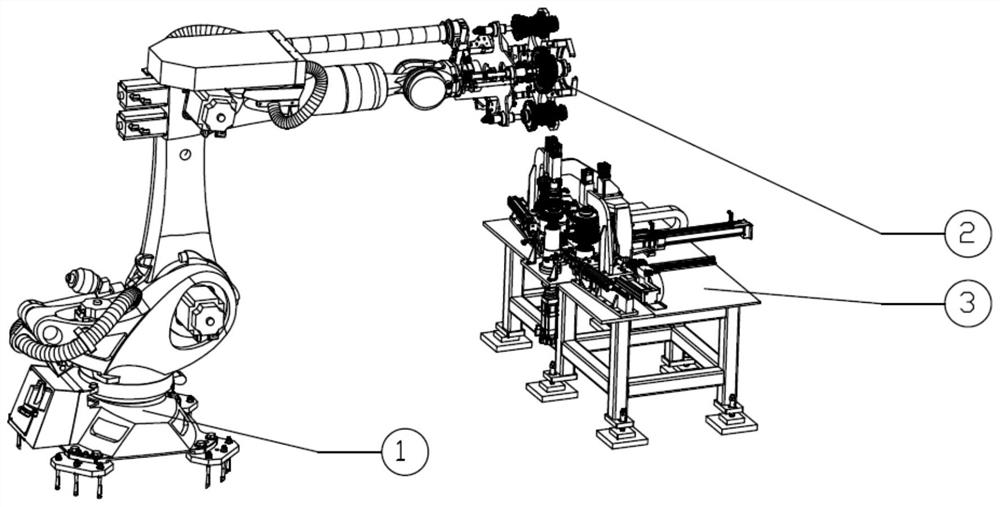

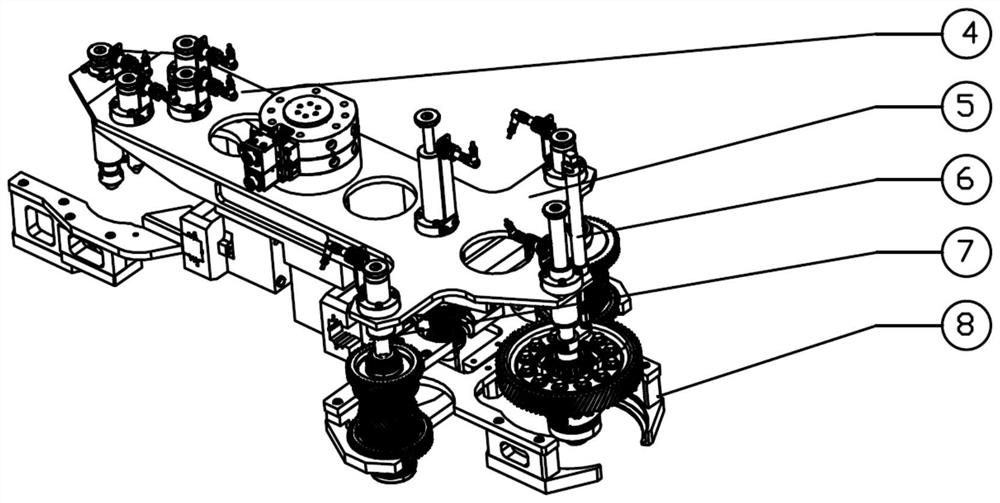

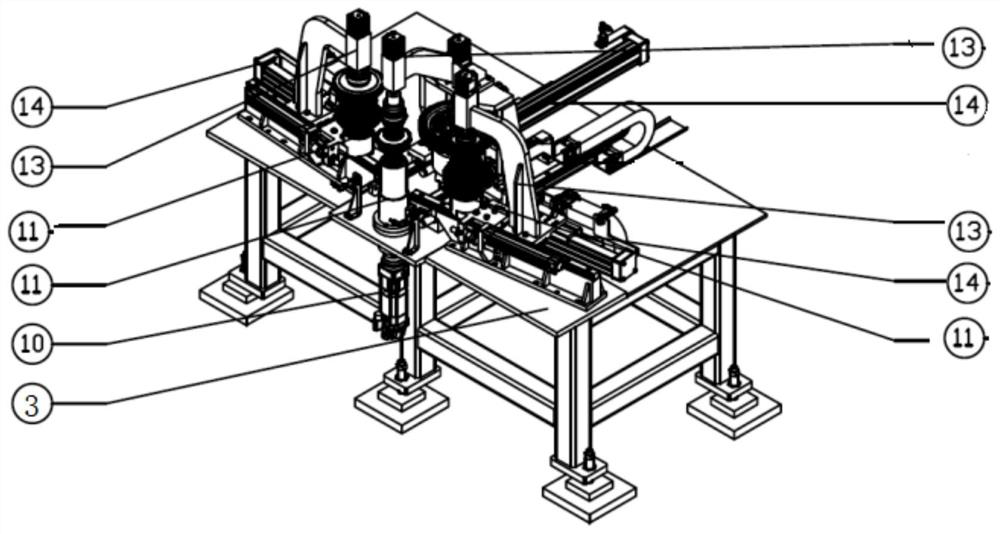

An automatic assembly meshing device

ActiveCN111113022BSave the beatReduce labor costsAssembly machinesWork holdersControl engineeringIndustrial engineering

Owner:COMAU SHANGHAI ENG

Dome valve and dome valve automatic control system used in pneumatic conveying system

ActiveCN106996464BSolution to short lifeEasy to replacePlug valvesOperating means/releasing devices for valvesAutomatic controlControl system

A dome valve for a pneumatic conveying system comprises a valve body, a semi-spherical valve element arranged in the valve body, a drive crank used for driving the semi-spherical valve element to rotate and a pneumatic executing element connected with the drive crank. The valve body comprises an upper valve body and a lower valve body which are assembled together. The upper valve body is provided with a valve opening and a seal air bag. The lower valve body is internally provided with a valve element installation seat. The dome valve has the beneficial effects that in the valve opening and closing process, the semi-spherical valve element does not make contact with the seal air bag or generate friction with the seal air bag during rotating, so that wear is avoided; and meanwhile, the semi-spherical valve element is long in service life and convenient to replace.

Owner:ZHEJIANG GUTE PNEUMATIC MACHINERY

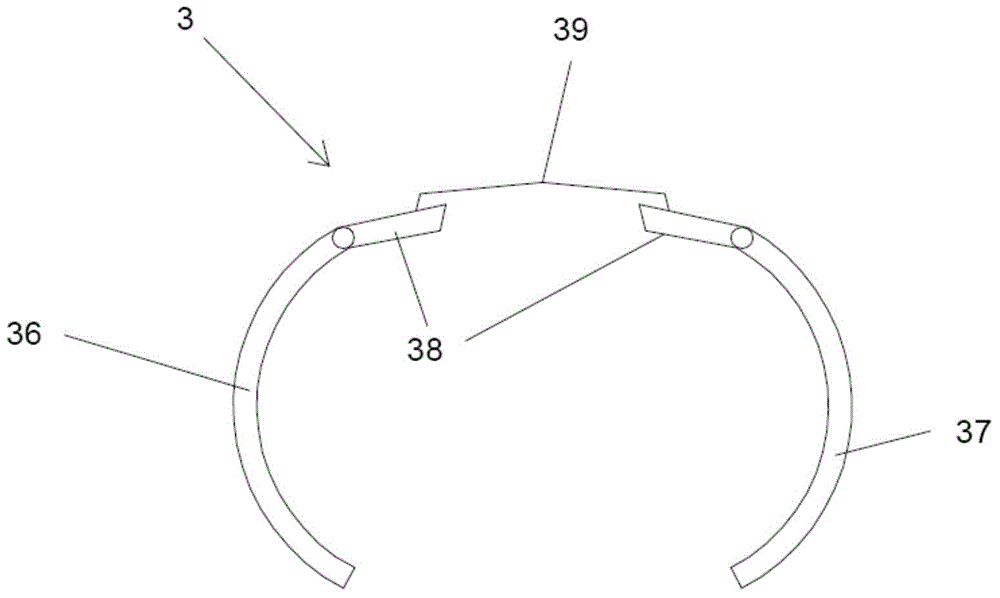

Arm vein tourniquet for assisting venipuncture

The arm vein tourniquet comprises a shell, a vein pressing module and a driving module, symmetrical guide grooves are formed in the two side walls of the shell, the vein pressing module comprises a vein pressing unit and a movable workbench, connecting frames are arranged on the two sides of the movable workbench, a movable workbench body is installed in the shell, and the driving module is connected with the connecting frames. The connecting frame extends out of the guide grooves in the two sides, the driving module is installed in the shell and connected with the movable workbench, and the driving module drives the movable workbench to slide in the axial direction of the shell. The pulse pressing unit comprises a shell, a disinfectant storage chamber and an air pump are distributed in the shell, and cameras, outer side disinfection nozzles and inner side disinfection nozzles are arranged on the two sides of a middle groove of the shell. Compared with the prior art, the nursing bed is simple in structure and high in integrity, does not occupy a large space, and is easy for medical staff to carry, disassemble and use; the fitting degree with the human arm is good; the sanitary safety coefficient is high.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com