Binding packer

A technology of packaging and machine head, which is applied to the parts of binding machinery and binding materials, etc., which can solve the problems of difficult handling, high cost and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

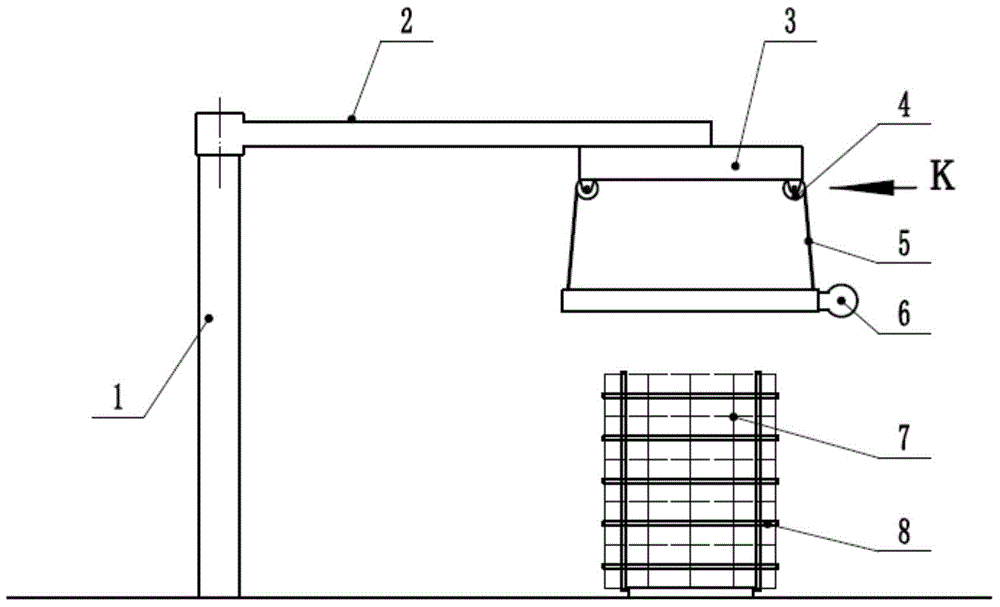

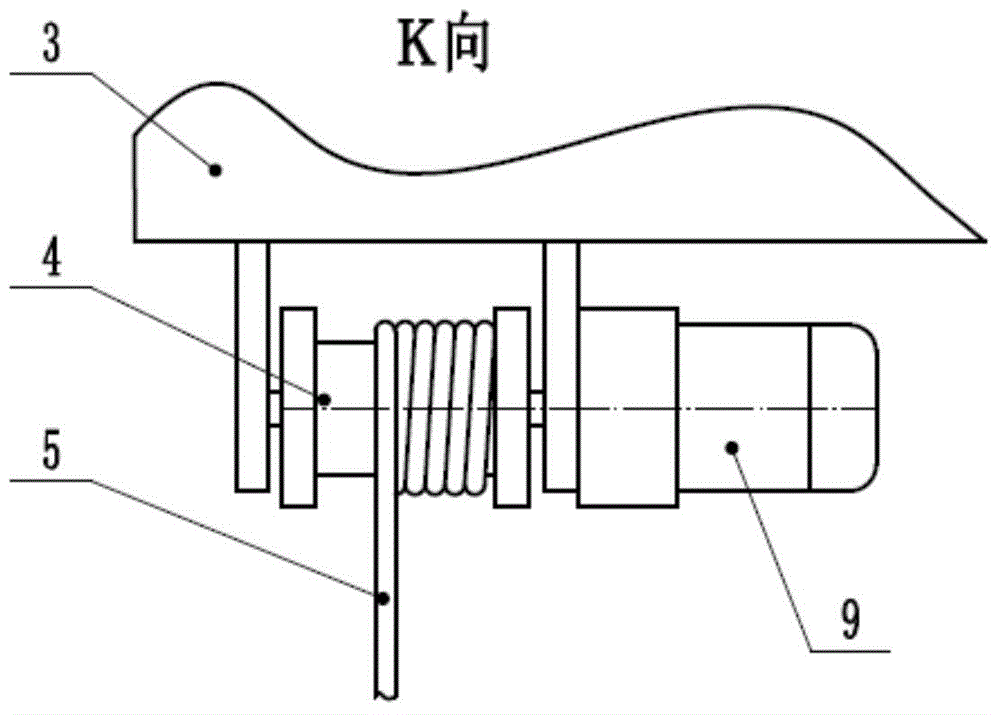

[0023] Such as figure 1 , figure 2 As shown, the site for packing materials in this example is provided with a pedestal (1) fixed on the ground, a cantilever (2) that can swing horizontally is hinged on the top of the pedestal, and a set of take-up wheels ( 4) on the top seat (3), the sling (5) is wound on the take-up wheel (4) with a power motor (9), the baler head unit (6) is connected to one end of the sling (5), and the power The motor (9) drives the take-up wheel (4) to retract and unwind the sling (5) and then pulls the baler head unit (6) to lift vertically. When performing packing work, the packing worker pulls the packing machine head unit (6) or the cantilever (2) to move horizontally, so that the packing machine head unit (6) moves to the top of the material stack (7) to be packed, and manually controls or pulls the crane The cable (5) lowers the baler head unit (6) to the position where the material is to be bundled, and the baler head unit (6) guides the packin...

Embodiment 2

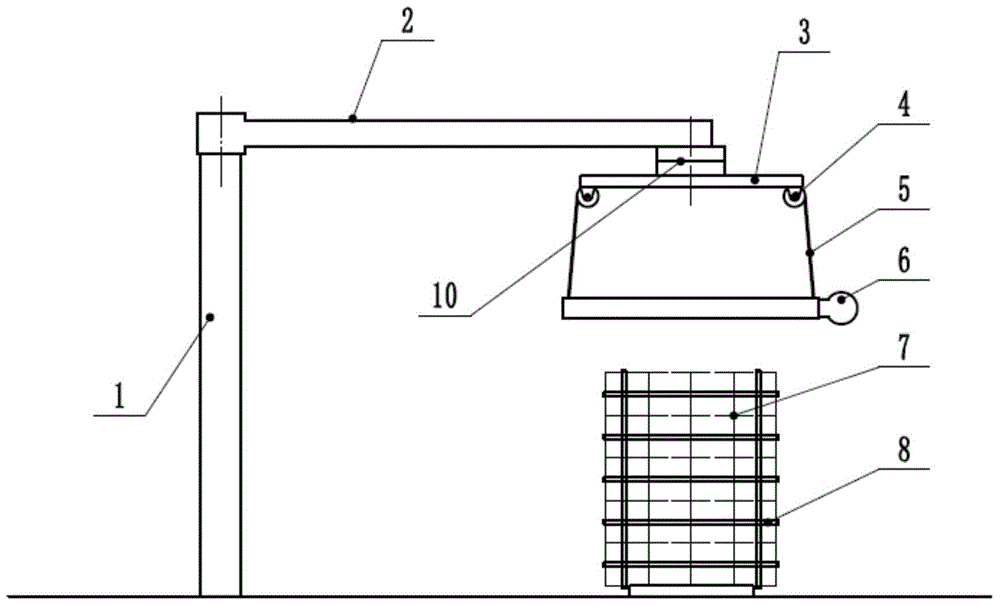

[0026] Such as figure 2 As shown, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that: the top seat (3) and the cantilever (2) are connected by a rotating seat (10), so that the packer head unit (6) and The top seat (3) can rotate horizontally arbitrarily, which is more conducive to aligning the packing head unit (6) with the material. The swivel seat (10) can also have its own power, which is more conducive to the realization of automatic control.

Embodiment 3

[0028] Such as image 3 As shown, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that the cantilever (2) has a slideway (11), and the top seat (3) has a pulley (12) that can slide on the slideway ). In this way, the baler head unit (6) is suspended under the cantilever (2) through the sling (5) and the top seat (3) slidingly, not only can it swing and move along the center of the hinge of the cantilever (2), but also can move along the cantilever ( 2) Radial movement to expand the working range of the baler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com