Dome valve for pneumatic conveying system and dome valve automatic control system

A technology of pneumatic conveying system and automatic control system, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of reduced sealing effect, high cost, and impact on use, and achieve the effects of avoiding wear, long life, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

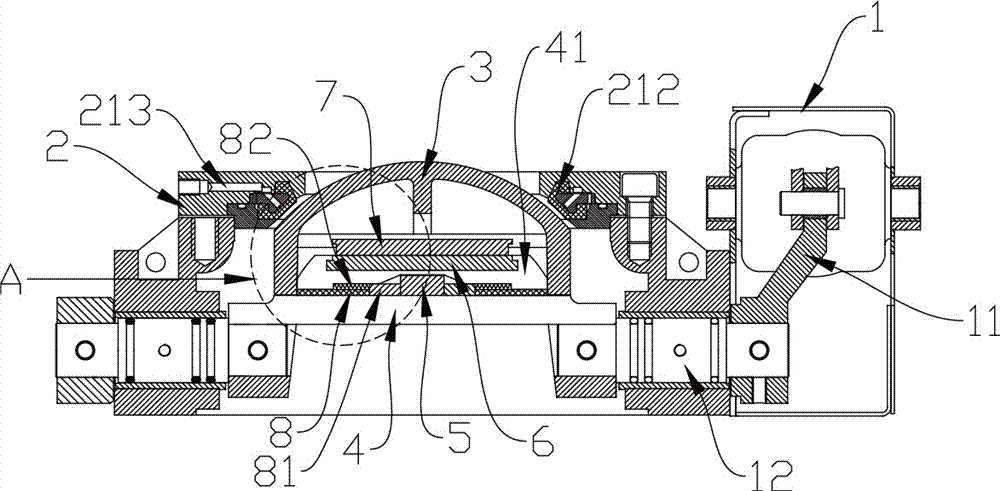

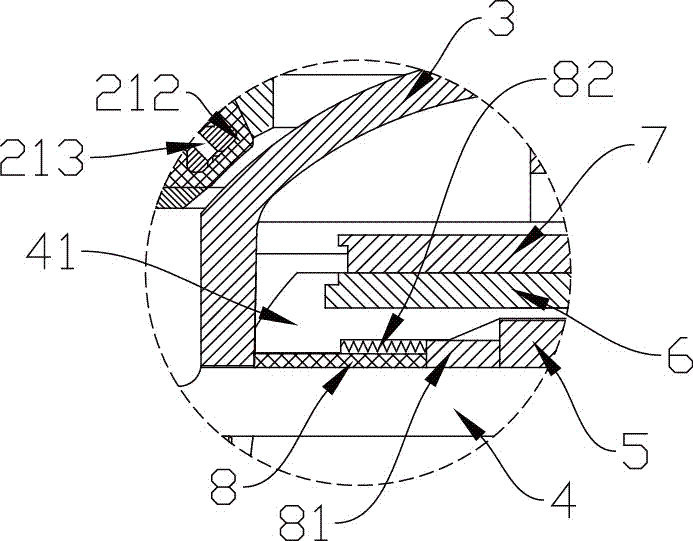

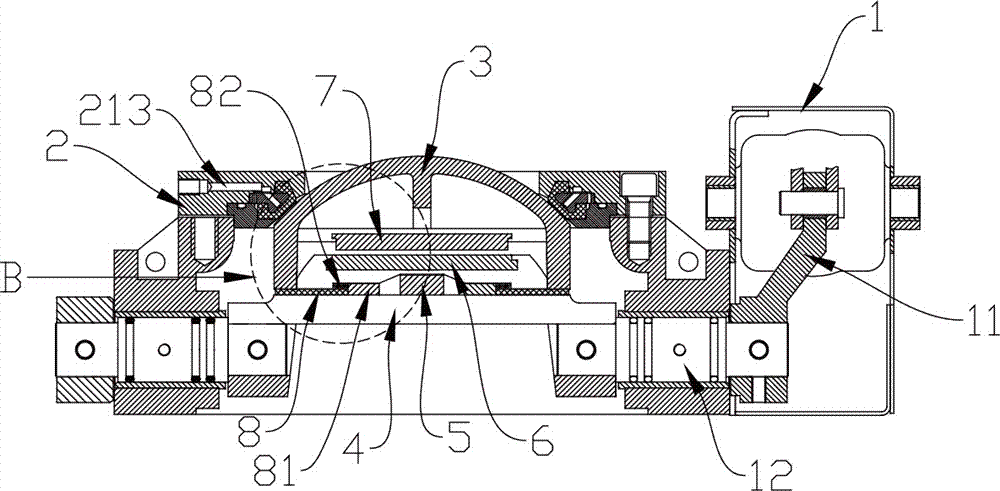

[0025] refer to figure 1 to Figure 6 , a dome valve used in a pneumatic conveying system, including a valve body 2, a hemispherical spool 3 arranged in the valve body 2, a driving arm 11 for driving the hemispherical spool 3 to rotate, and a driving arm 11 Connected pneumatic actuators, the valve body 2 includes an upper valve body 21 and a lower valve body 23 assembled together by bolts, the upper valve body 21 is provided with a valve port 211 and a sealing air bag 212, and the lower valve body 23 is provided with a valve core mounting seat 4, which is provided with a disc-shaped first electromagnet 6, and the hemispherical valve core 3 is provided with a disc repelling the first electromagnet 6. Shaped first magnet 7, the outer edge of the hemispherical valve core 3 is stuck on the protrusion 41 of the valve core mounting seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com