Powder mixing device

A mixing device and powder technology, which is applied to mixers with rotating stirring devices, mixers, mixing methods, etc., can solve the problems of difficult powder mixing, light labor, unevenness, etc., to achieve convenient processing, Reliable mixing and improved homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

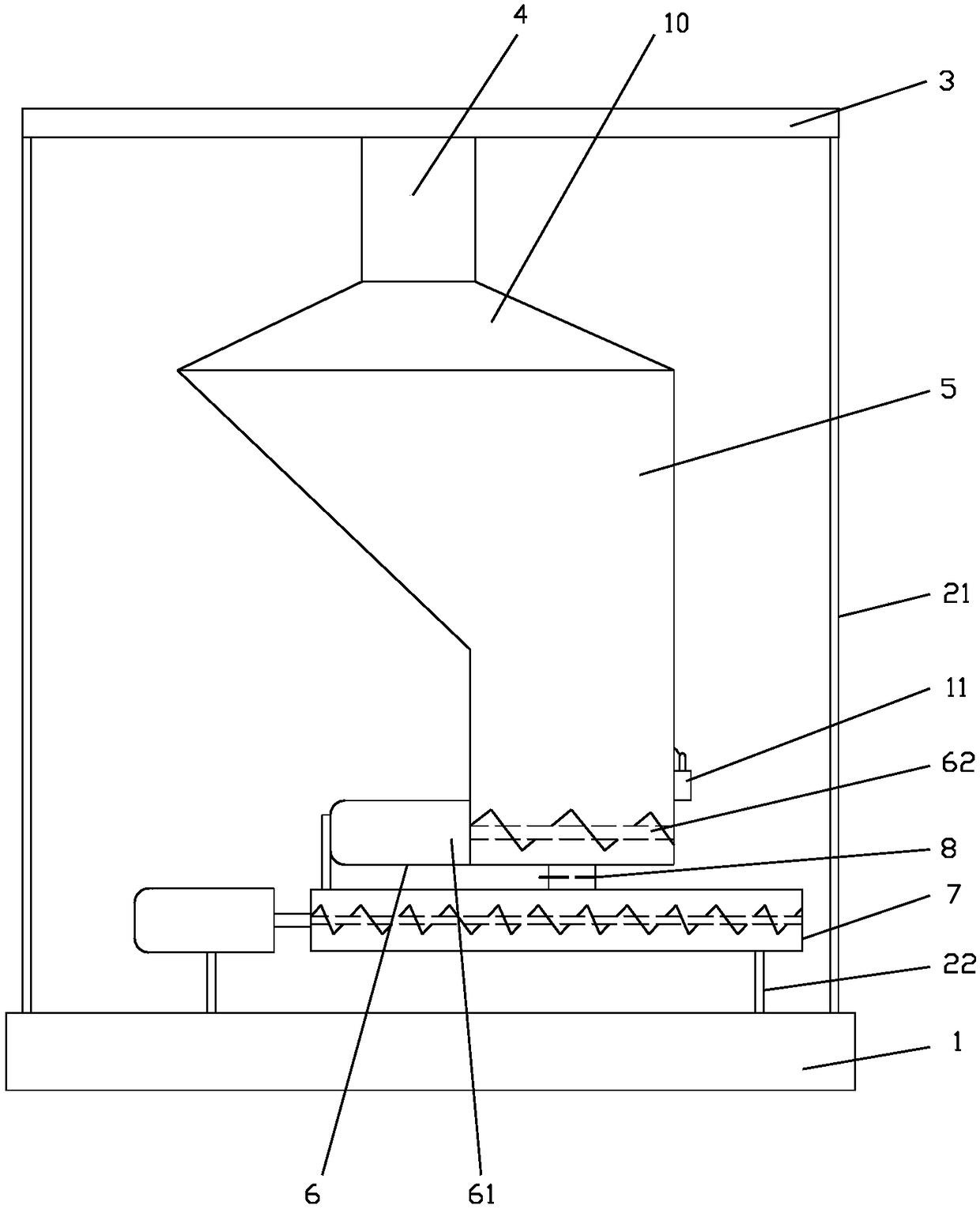

[0016] The present invention as Figure 1-2 As shown, it includes a workbench 1, the workbench is provided with a support platform 3 connected by a pole-21, and the support platform is provided with a discharge cylinder 4;

[0017] A stirring mechanism is provided between the support platform 3 and the workbench 1, and the stirring mechanism includes a feed bin 5, a stirring mechanism 6 and a screw conveyor 7, and the feeding port of the feed bin 5 is located below the discharge cylinder, Described agitating mechanism 6 is positioned at the bottom of feed bin, and described screw conveyor 7 is connected on the workbench by pole two 22, and the discharge port of described feed bin 5 communicates with the casing of screw feeder by branch pipe 11;

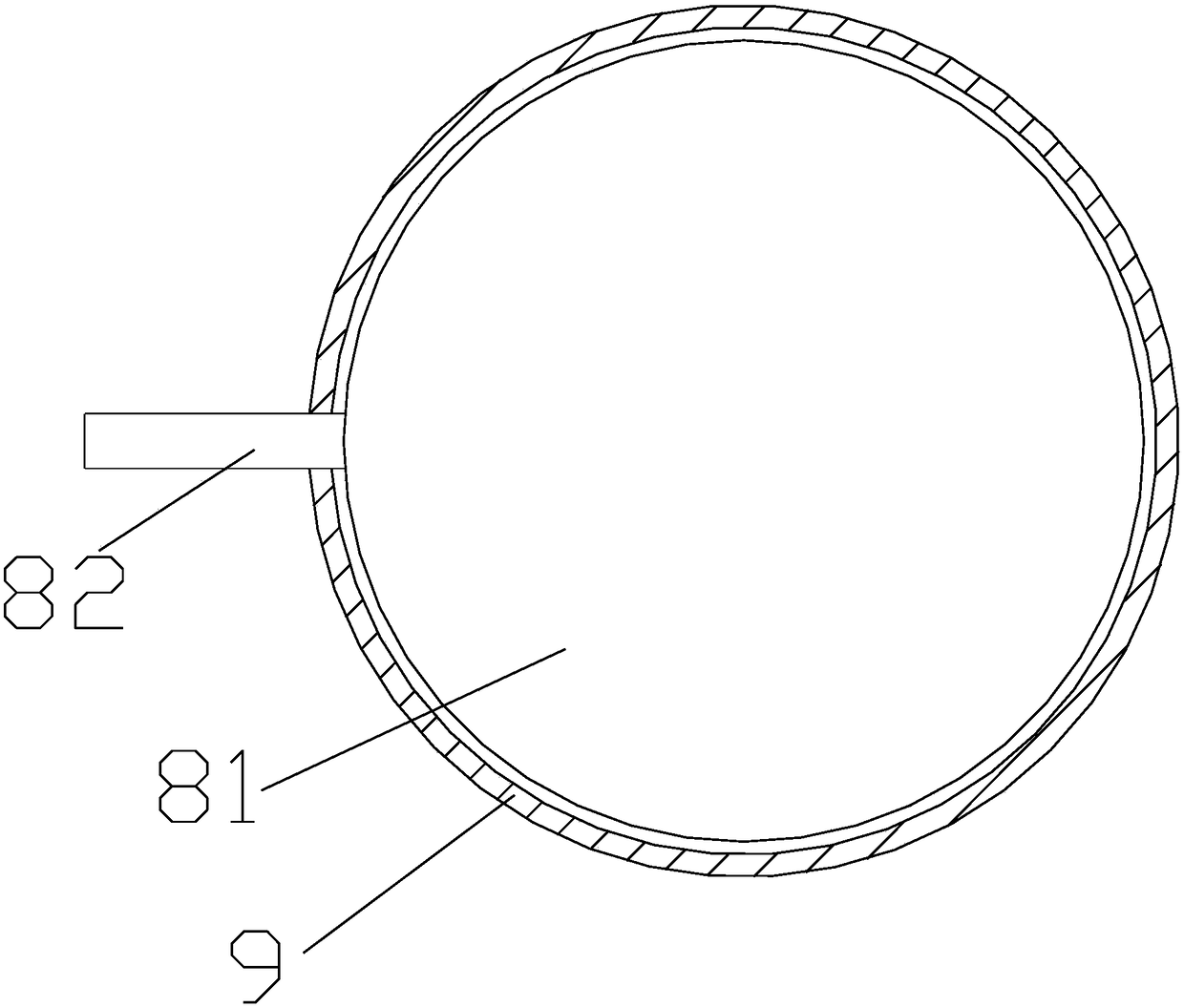

[0018] A rotary blocking piece 8 is arranged inside the branch pipe 9 . By setting the rotating baffle, the stirring mechanism can reliably carry out primary stirring, and then enter the screw conveyor for secondary stirring, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com