Oil drive variable pitch quadrotor type multifunctional fire-fighting unmanned aerial vehicle

A variable-pitch, four-rotor technology, applied in the field of drones, can solve problems such as slow and limited rescue speed, endangering the lives of firefighters, etc., and achieve good fire-fighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

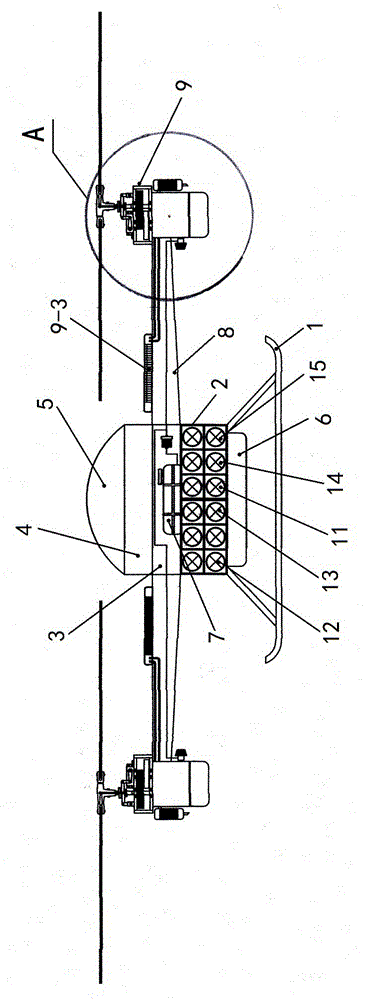

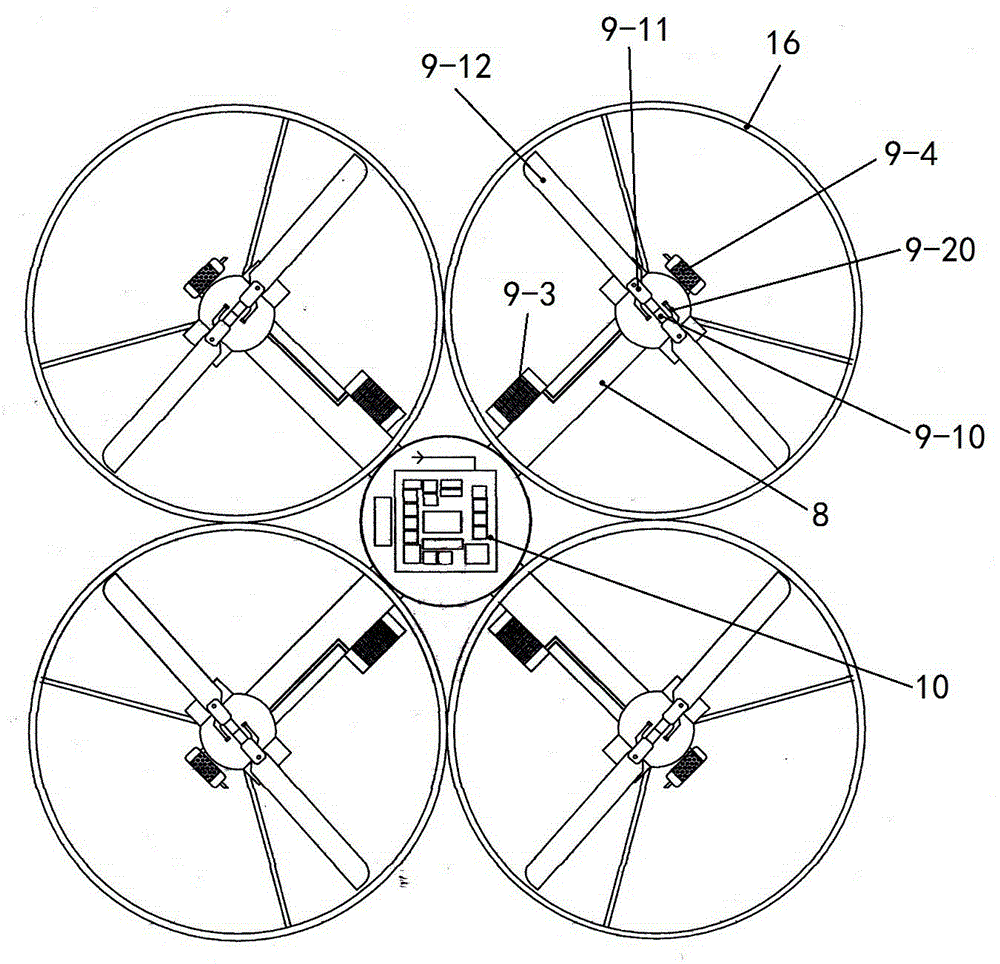

[0012] refer to figure 1 —3, it includes the cabin body and landing gear 1, the landing gear is fixed on the bottom of the cabin body, the cabin body is divided into material storage cabin 2, fuel storage cabin 3, electric control cabin 4 and umbrella cabin 5 from bottom to top, the outside of the bilge An airbag 6 is installed, and an autopilot module 10 is arranged in the electronic control cabin; a fuel tank 7 is installed in the fuel storage cabin, and four arms 8 are fixed outside the cabin, and a rotor mechanism 9 is installed on the outer end of each arm;

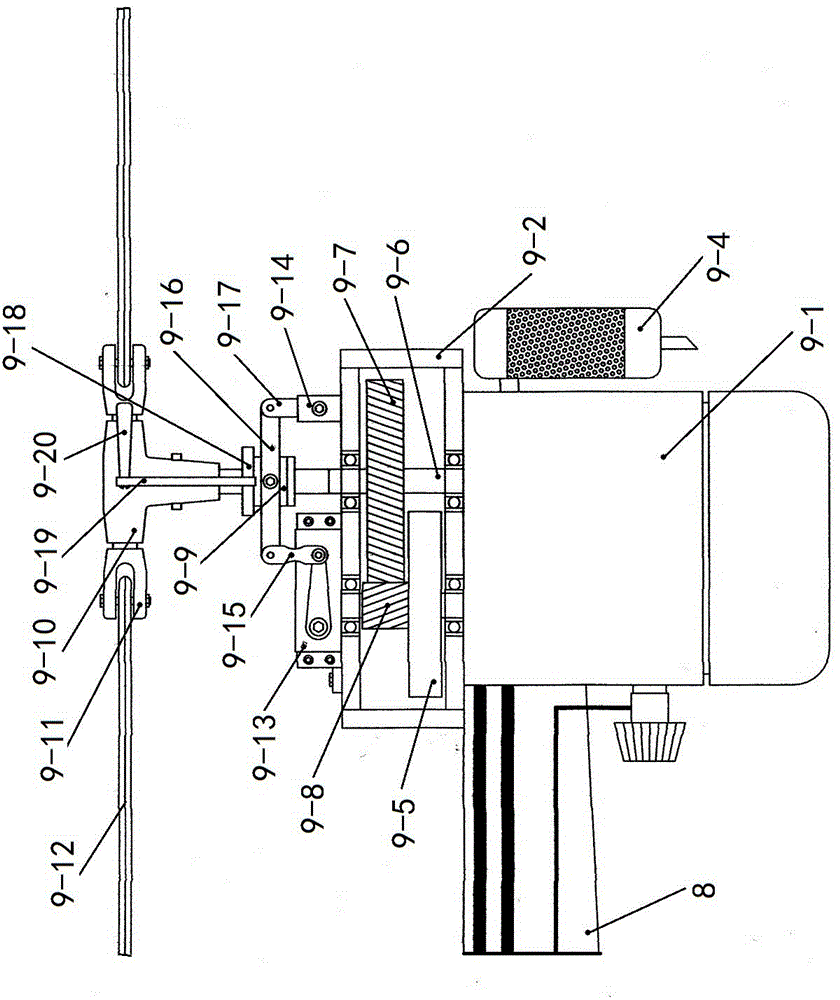

[0013] Rotor mechanism 9 comprises engine 9-1 and reduction box 9-2, and described engine is fixed on the outer end of machine arm, and reduction box is located at the top of engine, and reduction box is fixed on the machine arm, and the bottom of engine has safety air bag, The radiator 9-3 of engine is fixed on the machine arm top, and engine and radiator are connected by pipeline, and muffler 9-4 is also connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com