Electromagnetic wave-absorbing ceramsite concrete

A technology of ceramsite concrete and electromagnetic wave absorption, which is applied in the field of electromagnetic wave-absorbing ceramsite concrete and concrete materials that can absorb electromagnetic waves, and can solve the problems of large-scale use of construction projects, limited construction technology, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

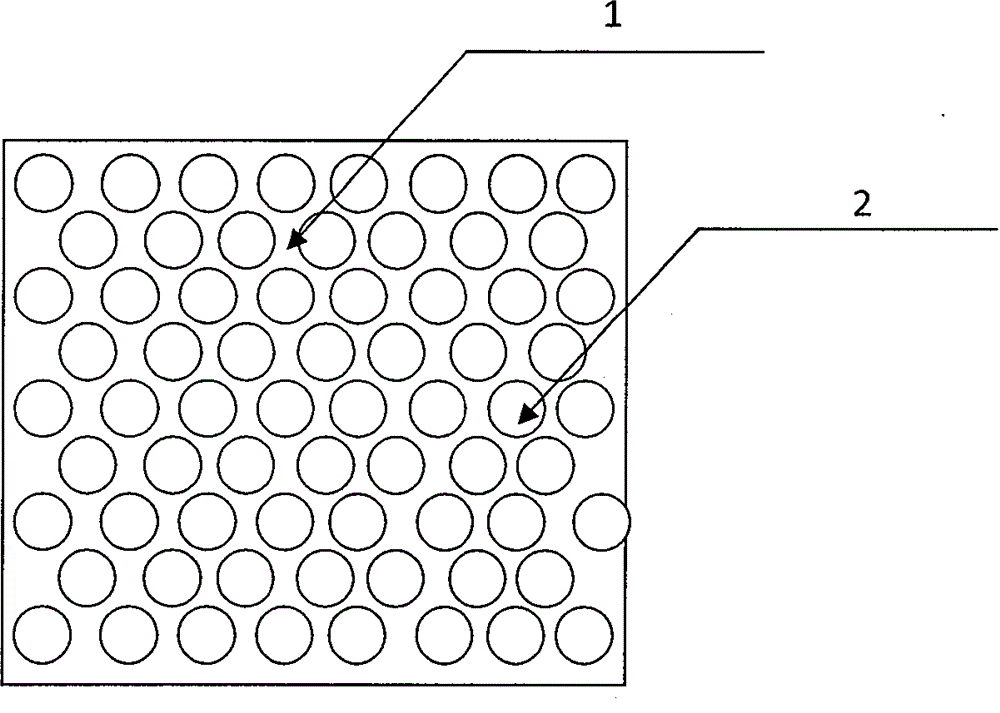

Image

Examples

Embodiment 1

[0013] Use 100kg of Portland cement clinker and 10kg of conductive graphite or conductive carbon black to mix and ball mill to obtain a particle size distribution of s / v=227828.62cm 2 / cm 3 ;s / g=7837.46m 2 / g; Dav=5.46μm, D[4.3]=5.46μm; D[3.2]=2.64μm powder, specific surface area 600m 2 / g or more, water-based gelling material with a surface resistivity of 500Ω / cm-3000Ω / cm.

[0014] Using 100kg particle size 2mm-5mm, the surface is microporous, and the specific surface area is 1200-15000m 2 / g of ceramsite, as aggregate.

[0015] The water-based cementitious material with conductive properties and the dry powder of ceramsite aggregate were mixed and stirred for > 10 minutes, then 36kg of water was added to wet mix and stirred for 10 minutes, poured into the mold for curing, and prepared as electromagnetic wave-absorbing ceramsite concrete specimen.

[0016] After testing, the electromagnetic absorbing ceramsite concrete specimen has a microwave absorption efficiency of 10d...

Embodiment 2

[0018] Use 100kg of Portland cement clinker and 10kg of conductive graphite or conductive carbon black to mix and ball mill to obtain a particle size distribution of s / v=227828.62cm 2 / cm 3 ;s / g=7837.46m 2 / g; Dav=5.46μm, D[4.3]=5.46μm; D[3.2]=2.64μm powder, specific surface area 600m 2 / g or more, water-based gelling material with a surface resistivity of 500Ω / cm-3000Ω / cm.

[0019] Using 200kg particle size 2mm-5mm, the surface is microporous, and the specific surface area is 1200-15000m 2 / g of ceramsite, as aggregate.

[0020] The water-based cementitious material with conductive properties is mixed with the dry powder of ceramsite aggregate for > 10 minutes, then 60kg of water is added for wet mixing and stirred for 10 minutes, then poured into the mold for curing, and the electromagnetic wave-absorbing ceramsite concrete specimen is prepared.

[0021] After testing, the electromagnetic absorbing ceramsite concrete specimen has a microwave absorption efficiency of 15dB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap