Wear-resistant sulfuric acid dew-point corrosion-resistant hot continuous rolling steel and manufacturing method thereof

A technology of dew point corrosion and sulfuric acid resistance, which is applied in the field of metal materials and its manufacturing, can solve problems such as poor wear resistance, and achieve the effect of improving corrosion performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

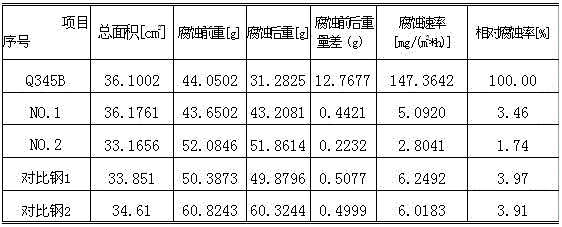

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with examples of implementation.

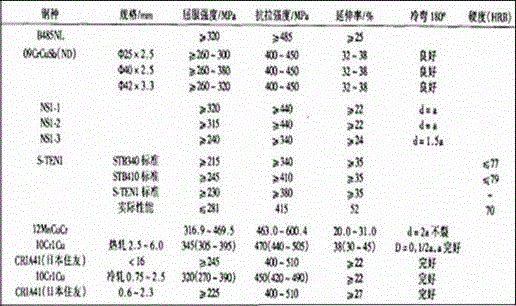

[0023] Adopt the traditional long process of iron and steel production and manufacturing: blast furnace ironmaking → hot metal pre-desulfurization → converter top-bottom compound blowing → Ar station / or LF furnace refining → continuous casting → continuous casting slab without defects → inspection → heating → rough rolling → finishing Rolling → cooling → coiling → finished hot-rolled coils. Production control requirements: Pre-desulfurization of molten iron to control the S element below 0.010%; converter top-bottom composite blowing, Ar station / or LF furnace refining to adjust C, Si, Mn, S, P, Cu, Sb, Nb and other components to Control requirements to ensure the purity of molten steel; full-blown Ar protection casting; after heating the slab to 1200°C in a heating furnace, rolling it on a continuous hot rolling mill; After controlled rolling in the crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com