A single-motor-driven vertical and horizontal double-type high-efficiency pulper without blind spots

A single-motor-driven pulper technology, used in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulping efficiency, single structure, and bottom blind area, etc., to increase work efficiency, reduce drive motors, and eliminate out of sync effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

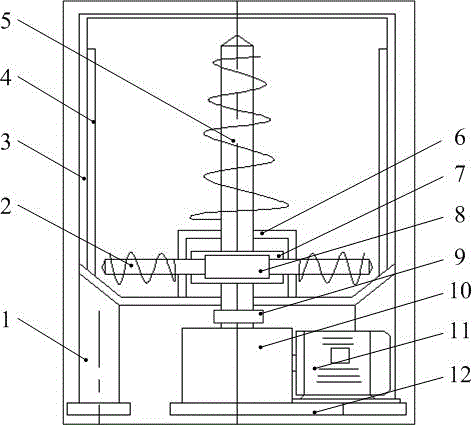

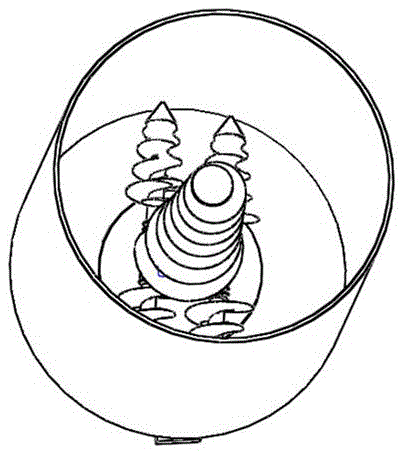

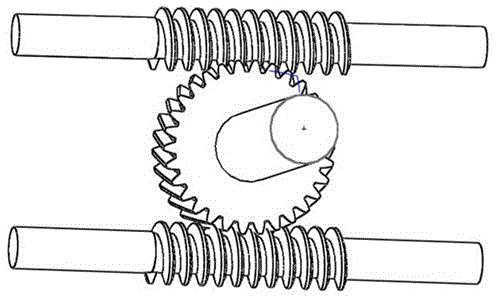

[0028] like figure 1 , figure 2 , image 3As shown, a single-motor-driven vertical and horizontal double-type high-efficiency pulper without blind spots is mainly composed of a shell structure, a driving device, a transmission device, and a pulping device. The shell structure is mainly composed of a base 12, a support 1, a tank body 3, and a raised baffle 4. The support 1 is installed under the tank body 3 to support the tank body 3, and the raised baffle plate 4 is installed on the tank body 3. Inside, the base 12 is installed under the tank body 3 for fixing the motor 11 and the reducer 10 . The driving device is driven by a single motor 11, and the motor 11 is installed under the pulper and fixed on the base 12 with bolts. The transmission device mainly includes a reducer 10, a coupling 9, a worm gear 7, a worm 8 mechanism and a protective cover 6. The reducer 10 is located inside the motor 11, the input end of the reducer 10 is connected with the motor 11, and the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com