Foundation pit top horizontal displacement monitoring method

A horizontal displacement and foundation pit technology, which is applied in excavation, foundation structure engineering, on-site foundation soil survey, etc., can solve the problems of high measurement cost, difficult realization, and high site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

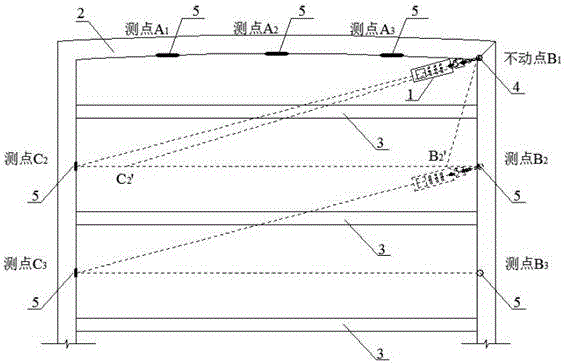

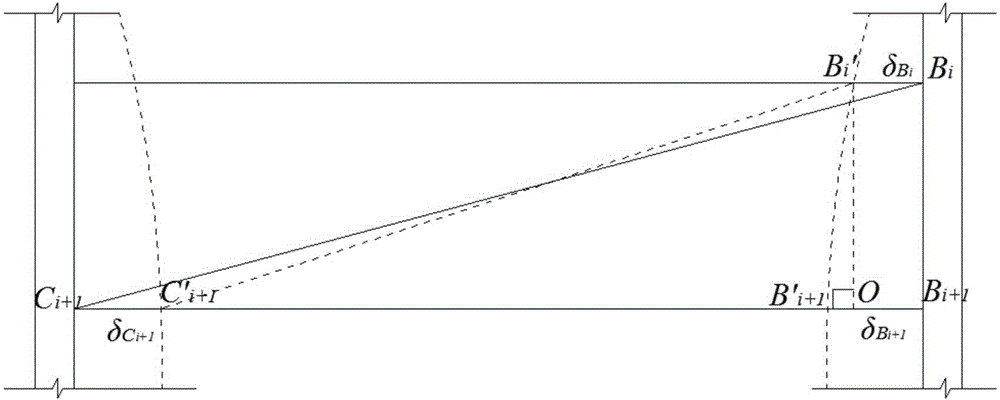

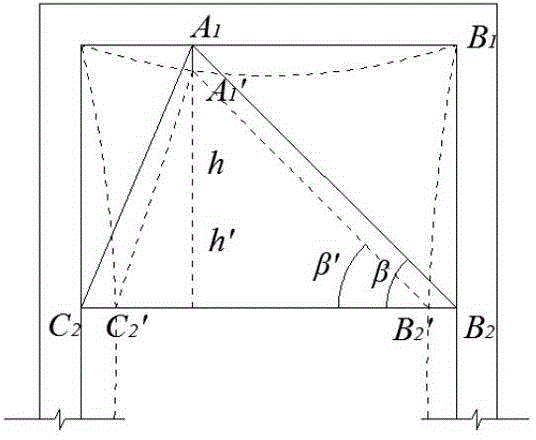

[0044] Below in conjunction with specific embodiment and accompanying drawing ( figure 1 , 2 , 3), the essence of the present invention is further elaborated.

[0045]1) Monitor the horizontal displacement of the top of the longitudinal two long sides

[0046] Such as figure 1 As shown, the horizontal displacement monitoring point B is set in sequence on the two long opposite sides of the long strip foundation pit 1 , B 2 , B 3 ..., C 2 、C 3 ..., where B 1 is the corner point of the foundation pit, and the distance between the two monitoring points is monitored regularly. measured in B 1 Point B is used as a reference fixed point. During the whole excavation process, the fixed point B 1 The displacement is 0.

[0047] When asking for B 2 、C 2 For the absolute displacement of the two points, first use the rangefinder to measure B before excavation of the foundation pit 1 to B 2 , B 2 to C 2 After the excavation of the foundation pit, the rangefinder is used reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com