Three-dimensional Displacement Measurement Method Based on Shape Correlation Computation

A technology of displacement measurement and correlation calculation, which is applied in the direction of measuring devices, instruments, and optical devices, etc., and can solve the problems of high uniformity of illumination and artificial speckle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

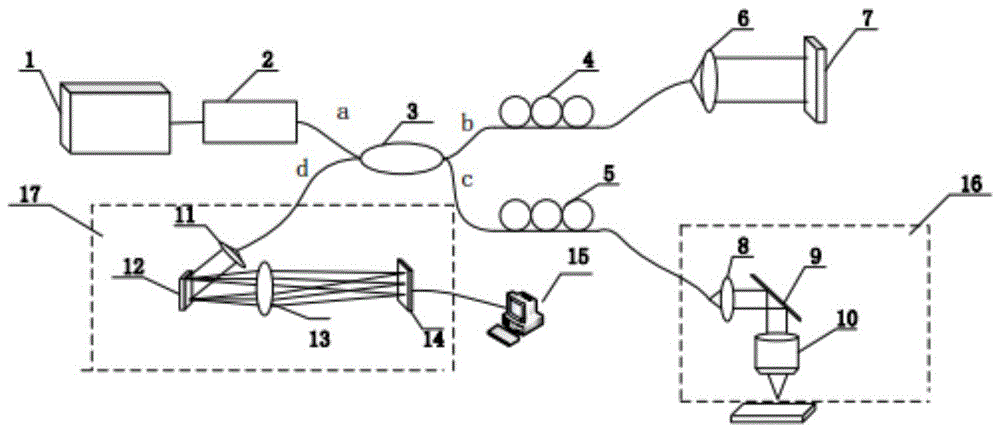

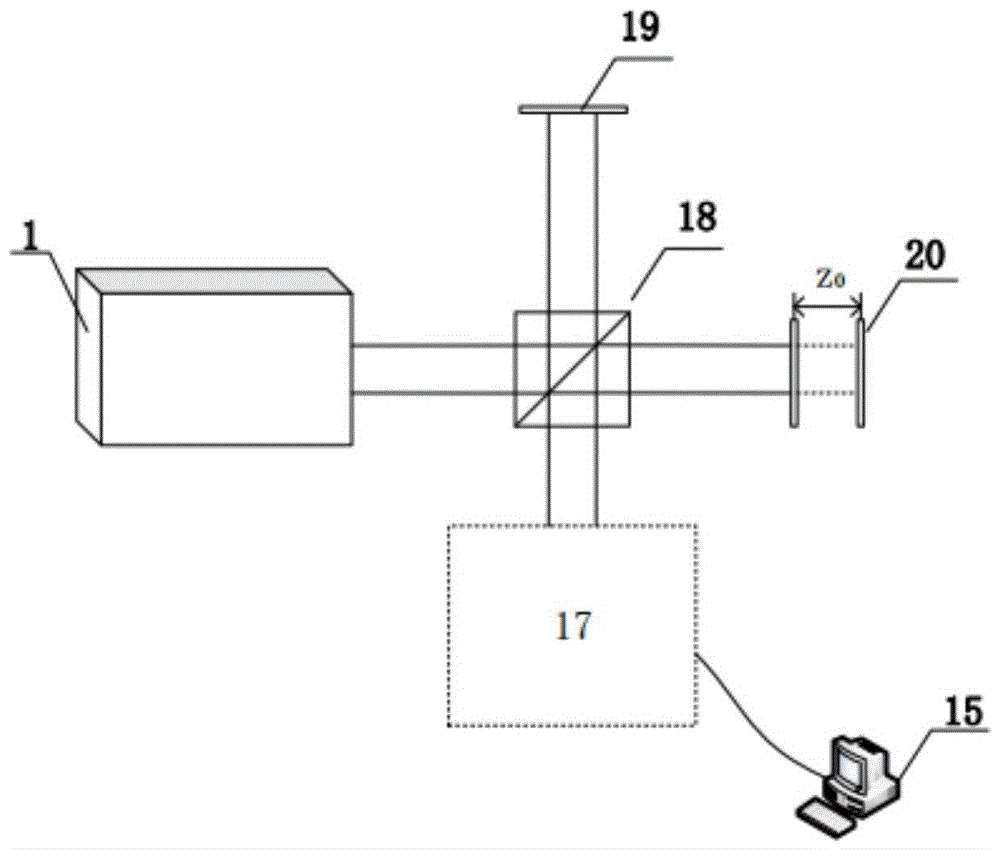

[0050] see first figure 1 and figure 2 , figure 1 It is the main optical path diagram of the three-dimensional displacement measurement method of the present invention to realize the shape correlation calculation, figure 2 is the free-space optical path diagram for calibrating the spectral system in the present invention. The light source 1 used in the embodiment of the present invention is a supercontinuum broadband laser light source with a center wavelength of 840 nm and a bandwidth of 50 nm.

[0051] The single deflection angle of the two-dimensional scanning galvanometer 9 is 0.02 °, and the focusing system 10 is a ThorlabsLSM04-BB lens, and the focal length of its lens is 18.9mm, and the working distance is 42.3mm, and dx=dy=6.6 um;

[0052] The number of pixels M=2048 of the streak camera 14 used;

[0053] The size of the component to be tested is 0.5mm*0.3mm;

[0054] The two-dimensional scanning range is 2.64mm*2.64mm;

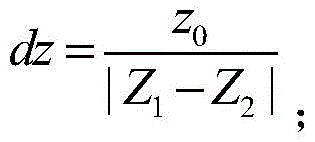

[0055] The three-dimensional displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com