Spring strength fatigue testing device

A fatigue test and strength technology, applied in the field of spring strength fatigue test device, can solve the problems of wasting labor costs, difficult to ensure constant spring pressure, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

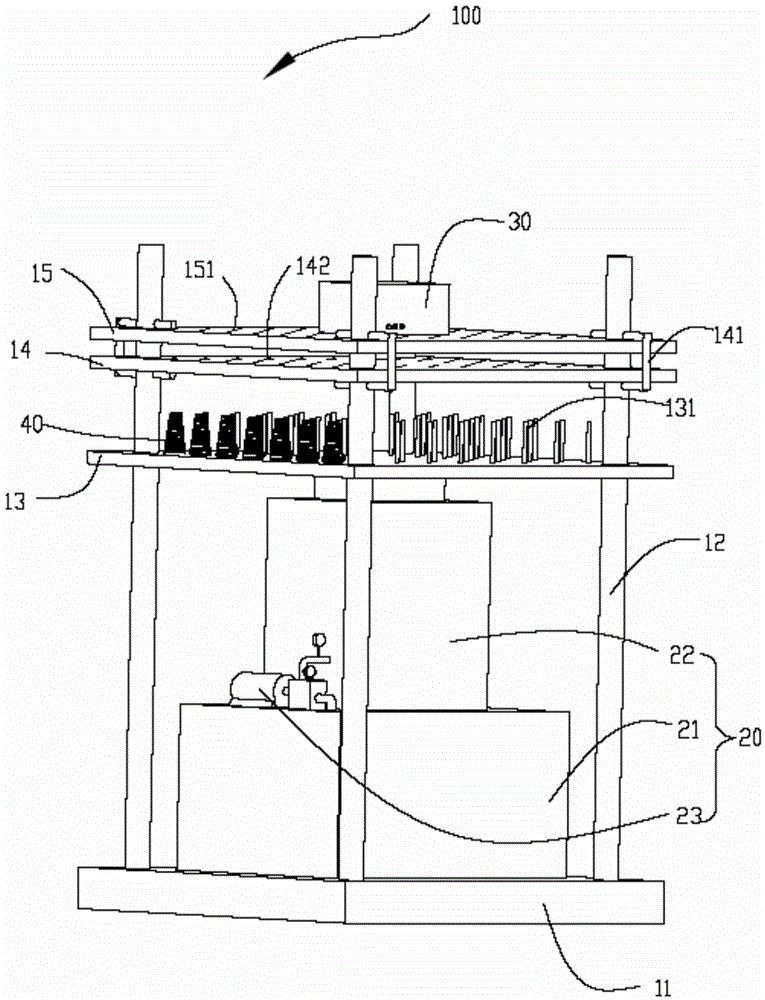

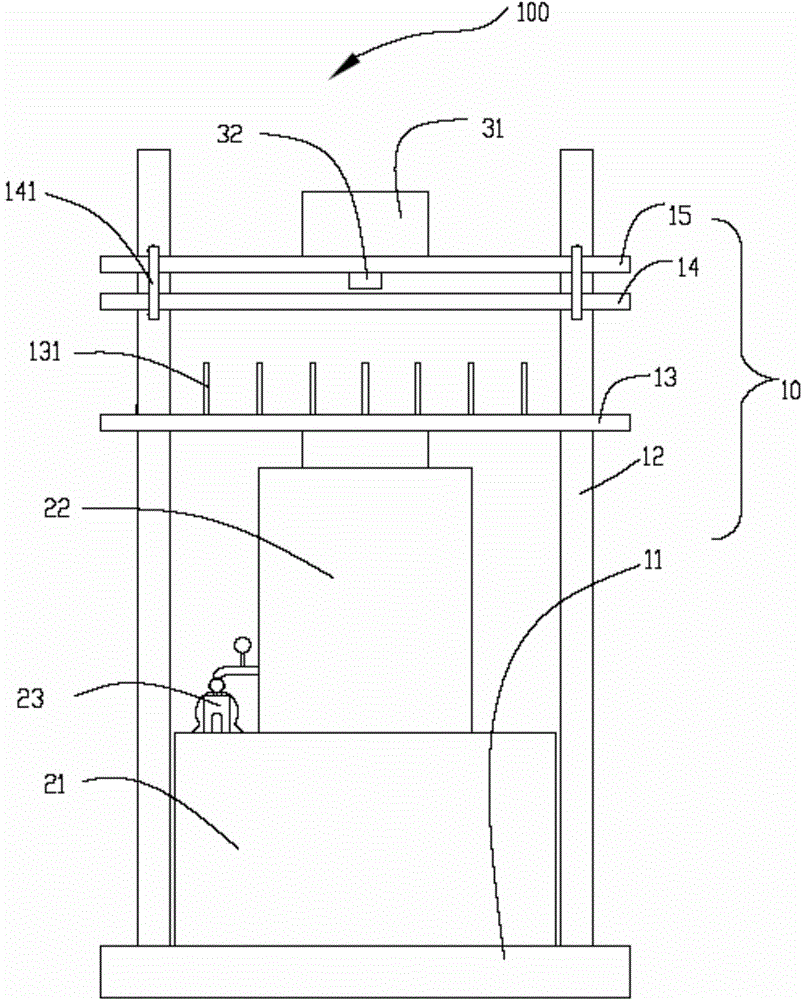

[0020] see figure 1 and figure 2 , a preferred embodiment of the present invention provides a spring strength fatigue testing device 100 . The spring strength fatigue testing device 100 is used for fatigue testing of spring strength. The spring strength fatigue testing device 100 includes a carrier frame 10 , a driver 20 and a pressure sensor 30 .

[0021] The bearing frame 10 is used for bearing the springs of the test for testing. The carrying frame 10 includes a base plate 11 , a plurality of fixed guide columns 12 , a movable carrying plate 13 , a first pressing plate 14 and a second pressing plate 15 . Wherein, the base plate 11 , the movable bearing plate 13 , the first pressing plate 14 and the second pressing plate 15 are arranged parallel to each other. The plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com