Flexible non-directional contact-type sensor

A contact sensor, non-directional technology, applied in the field of sensors, to achieve the effect of low shape and position accuracy requirements, increase the range of installation and use, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

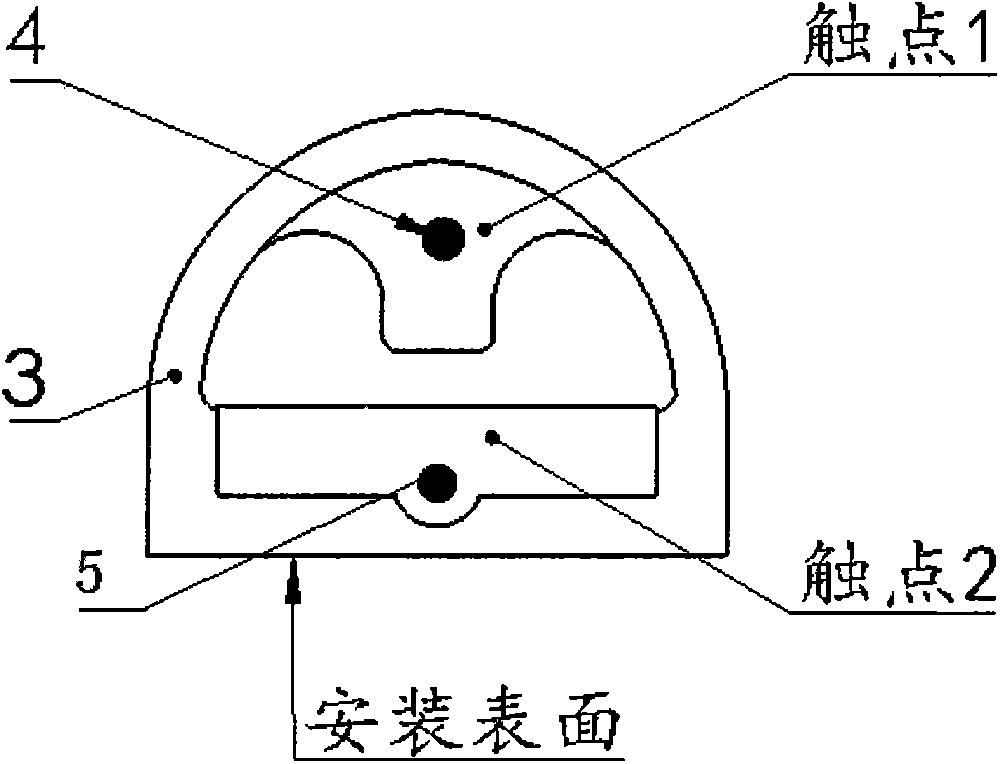

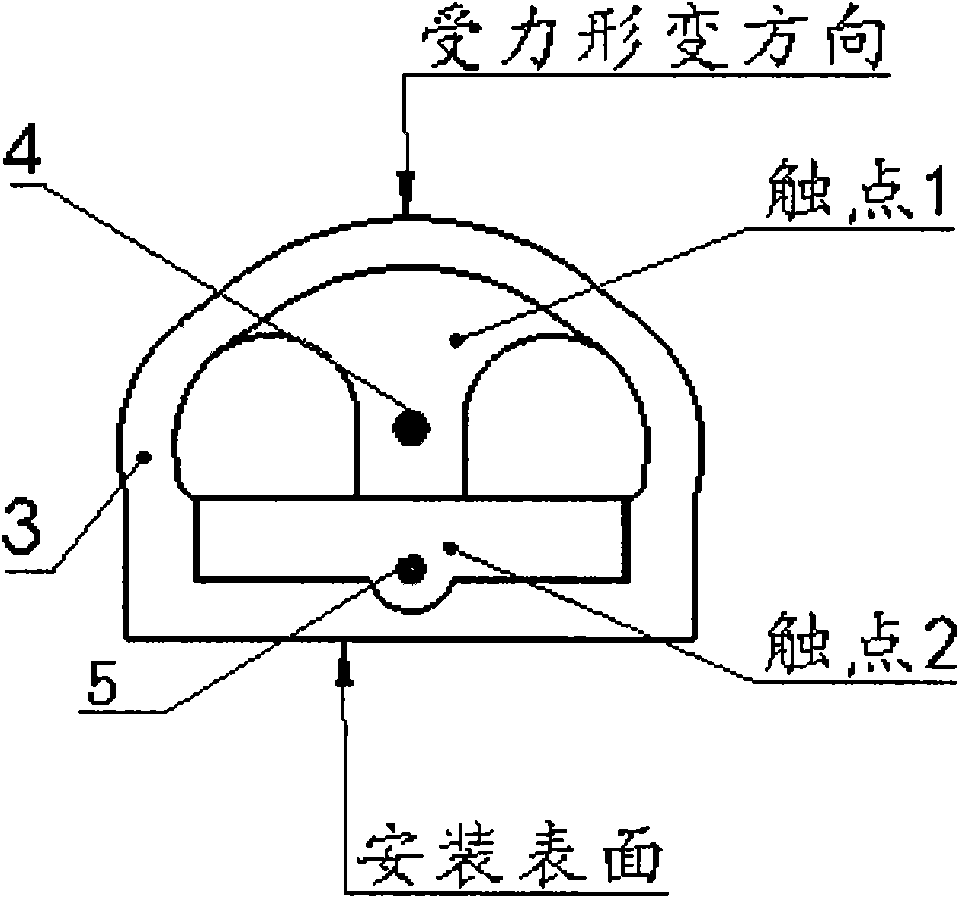

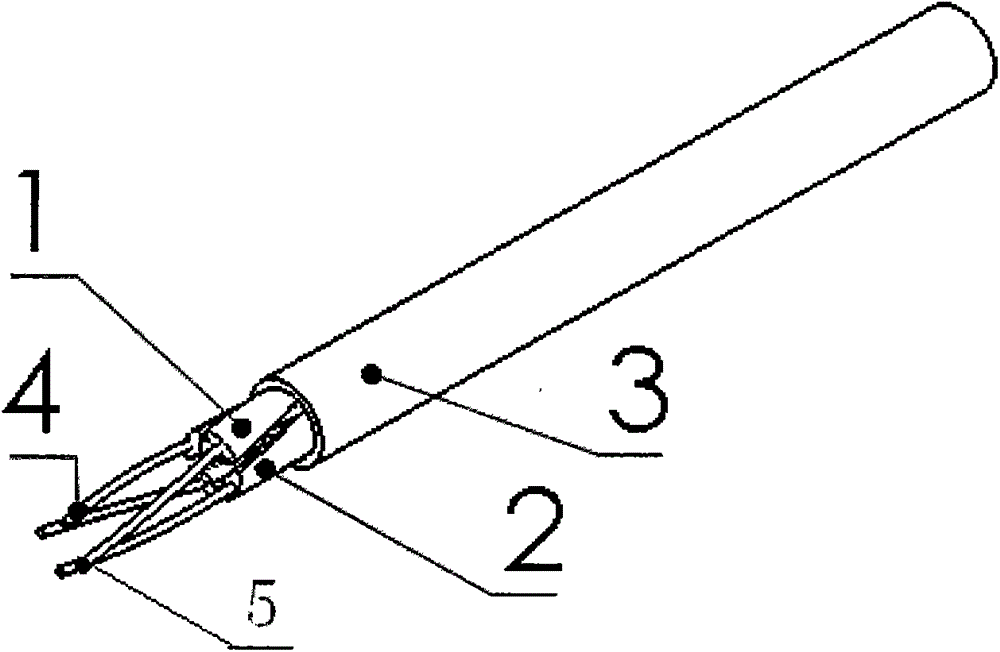

[0015] figure 2 The basic outline drawing of the 4-wire flexible non-directional contact sensor provided for the present invention; image 3 It is a schematic diagram of the distribution of the flexible antenna 1 and the flexible antenna 2 of the 4-wire type flexible non-directional contact sensor in the elastic insulating tube provided by the present invention. Such as Figure 2-3 As shown, the flexible non-directional contact sensor provided by the present invention includes a first flexible contact terminal 1, a second flexible contact terminal 2 and an elastic insulating hose 3, and the first flexible contact terminal 1 and the second flexible contact terminal 2 are spaced apart from each other and combined with the inner wall of the hose 3 in a helical manner along the axial direction of the hose 3 . The cross sections of the first flexible contact terminal 1 and the second flexible contact terminal 2 are circular or oval.

[0016] Both the first flexible contact term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com