A vertical axis wind power generator

A technology of wind power generation device and vertical axis, which is applied in the direction of wind power generation, wind power engine, wind power motor combination, etc. It can solve the problems of high wind speed requirements, limit the scale of wind power generation device, limit the installation range of wind power generation device, etc., and achieve the improvement of power generation efficiency , Improve space utilization, expand the effect of installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

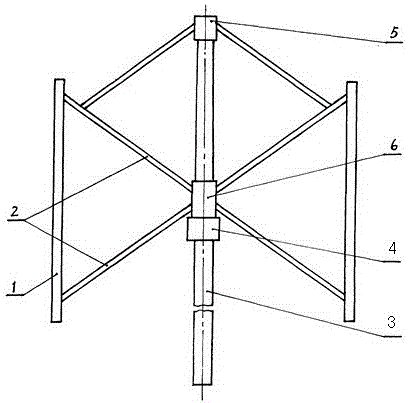

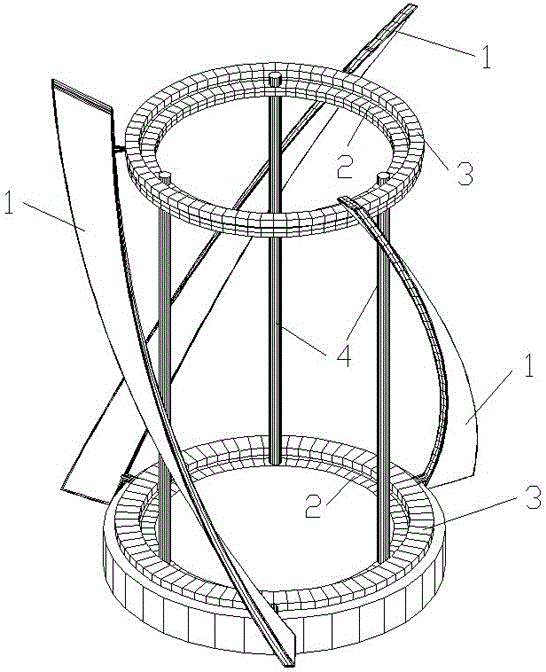

[0028] Such as figure 2 As shown, the first embodiment of the vertical axis wind power generation device of the present invention includes a first blade group composed of blades 1, a rotating member for the blades 1 to rotate around, and a connecting body 3 for movably installing the blade 1 on the rotating member. And the generator (not shown), also includes the support body 4, under the action of wind, the blade 1 rotates around the rotor to drive the generator to generate electricity.

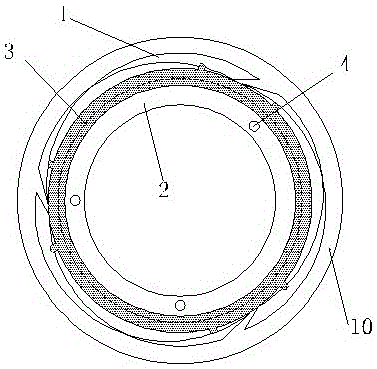

[0029] Such as figure 2 As shown, the number of blades 1 in the first blade group is not less than two, and in this embodiment is three. The rotating part is an annular track 2 , and the connecting body 3 is annular. The blades 1 in the first blade group are fixed on the outside of the connecting body 3 and evenly distributed around the annular track 2 . The circular track 2 is a circular track, and the connecting body 3 is supported on the upper surface of the circular track. On the opp...

Embodiment 4

[0041] The way of installing the rotating shaft in the fourth embodiment is as follows: a vertical shaft 11 is installed in the middle of the wind power generation device in the first embodiment, and the upper end of the vertical shaft 11 passes through the annular track 2 and the annular connecting body 3, and the rotating shaft 5 The movable sleeve is on the top of the vertical shaft 11, and driven by the wind, the second blade group and its rotating shaft 5 rotate around the vertical shaft 11. The lower end of the second blade group is horizontally provided with an annular body 12 , and the lower end surface of the annular body 12 is provided with a recess for accommodating the connecting body 3 , and the connecting body 3 is accommodated therein. The magnets as the generator stator and the coils as the generator rotor are respectively arranged on the annular body 12 and the connecting body 3 . Under the action of wind force, the first blade set and the second blade set mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com