Improved Feed Mechanism for Roller Ball Base Surface Grinding and Its Using Method

A technology of grinding processing and feeding mechanism, which is applied in the direction of spherical grinding machines, grinding machine parts, grinding drive devices, etc. It can solve the problems of poor feed control, large size dispersion, and processing burns, etc., to achieve Improve processing efficiency and surface quality, shorten processing time, and reduce dimensional dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

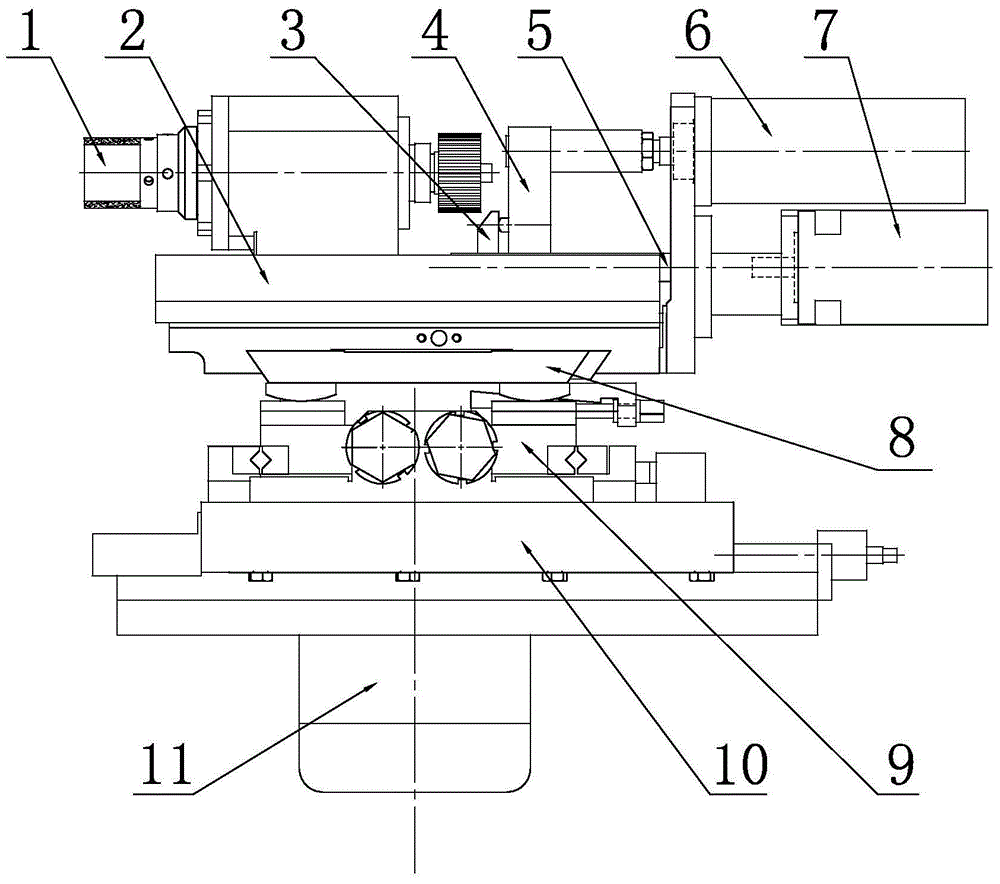

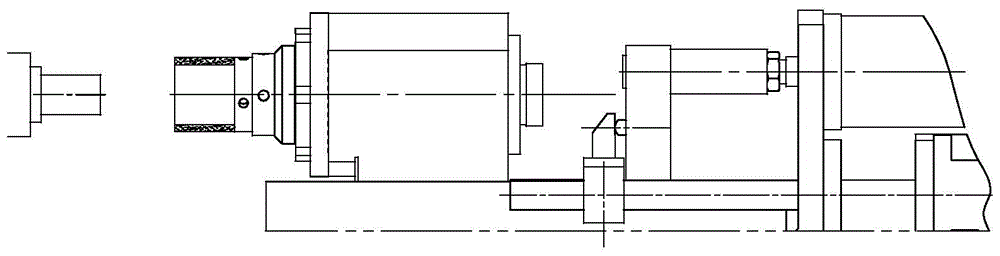

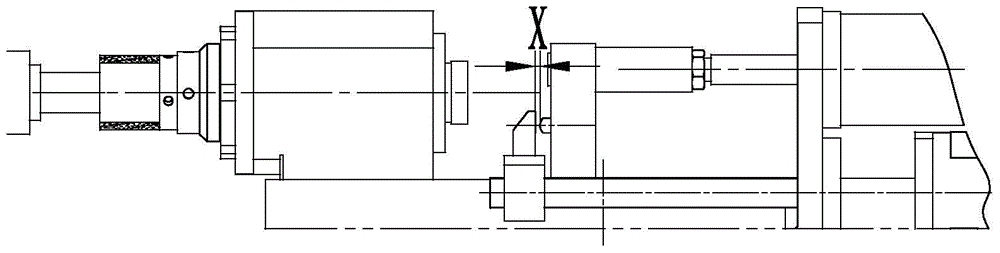

[0035] The accompanying drawings show embodiments of the present invention, and the embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be construed as limiting the present invention. The scope of protection of the present invention is based on the contents of the claims. Any basis The replacement of equivalent technical means made in the specification does not depart from the protection scope of the present invention.

[0036] The overall technical structure of this embodiment is as shown in the figure, which includes a grinding wheel 1, a feed carriage 2, a cylinder 6 and a control device. The cylinder 6 and the servo motor 7 are set on the carriage support, the feed carriage 2 and the carriage support are connected by a rolling linear guide rail, and the working end of the cylinder 6 is connected to the feed push block set on the feed carriage 2 4 connection, the trigger block 3 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com