Locating mechanism of bearing grinder

A technology of positioning mechanism and bearing grinding machine, which is applied in the direction of grinding the workpiece support, etc., can solve the problems of destroying the accuracy of the reference plane, wear, and aggravation, and achieve the effects of reducing the frequency of replacement, improving the dimensional accuracy, and reducing the size dispersion

Inactive Publication Date: 2007-09-12

南通山口精工机电有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The original rear positioning plate and rear support are made of YG6 cemented carbide material, which is a micron-sized powder of high hardness and refractory metal compound (mainly WC, TIC, etc., also known as high-temperature carbide). Powder metallurgy products sintered with metals such as cobalt or nickel as a binder, but the HV only reaches about 1300-1800. Usually, the phenomenon of wear and tear will appear after less than a month of use, and it will become more and more serious, which seriously damages the reference surface. Accuracy requirements, which directly affect the dimensional accuracy of the workpiece, that is, the dimensional accuracy of the inner and outer wheels, often result in batch rework, and also increase the frequency of stopping the machine to replace the rear positioning plate and rear support

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

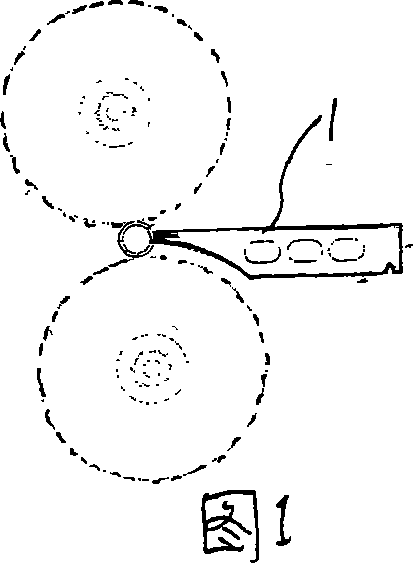

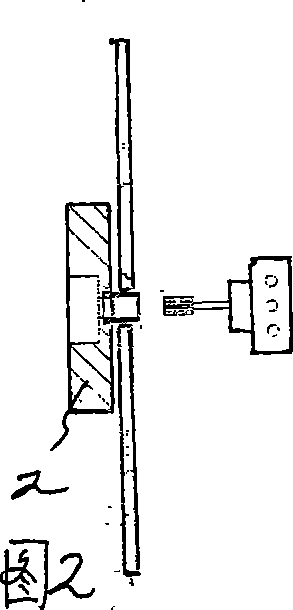

[0014] A positioning mechanism for a bearing grinder, comprising a rear positioning plate 1 and a rear support member 2, the rear positioning plate 2 is made of diamond material. The rear support 2 is made of diamond material. The verticality and parallelism of the rear positioning plate and the rear support are within 1 wire.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention discloses one kind of locating mechanism of bearing grinder. The locating mechanism includes one back locating plate and one back support piece, which are made with one identical diamond material with very high hardness of HV near 10000 and has service life as long as 6-8 times that of YG6 hard alloy. The present invention can ensure the long term stability of the grinder and greatly raised size precision of the workpiece.

Description

Technical field: [0001] The invention relates to a positioning mechanism of a grinding machine. Background technique: [0002] In the existing positioning mechanism of the grinding machine used for manufacturing bearings, the rear positioning plate and the rear support are used as the end face datum plane of the inner and outer rings and the outer circle datum plane in the grinding of the inner and outer wheels of the bearing. Usually, the end face datum is also called the A datum, and the outer circle datum Called the B benchmark. The rear positioning plate is mainly used to support the end faces of the inner and outer wheels, and the rear support is used to support the excircles of the inner and outer wheels. [0003] The original rear positioning plate and rear support are made of YG6 cemented carbide material, which is a kind of high hardness and refractory metal compound (mainly WC, TIC, etc., also known as high-temperature carbide) micron-sized powder. Powder metallu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B41/06

Inventor 刘卫平莫锋

Owner 南通山口精工机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com