Rubber ring mold

A rubber ring and mold technology, applied in the field of rubber ring molds, can solve the problems of unfavorable management, high mold cost, and many molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

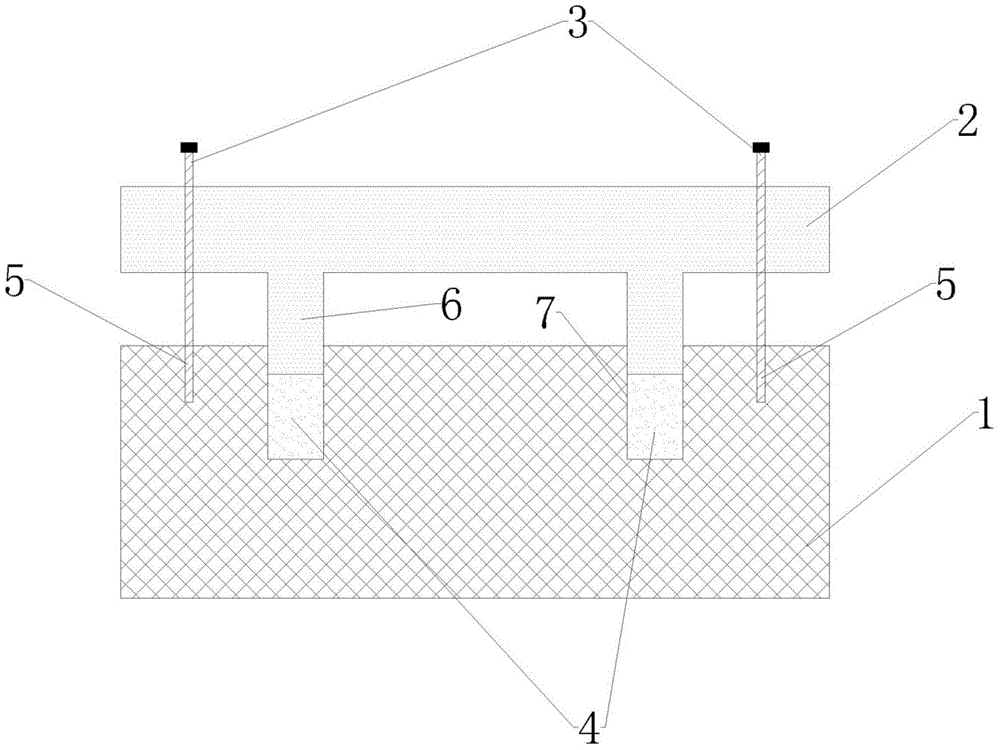

[0012] according to figure 1 The rubber ring mold shown has a lower die 1 and an upper die 2, the lower die 1 has several threaded holes 5 and grooves 7, the upper die 2 has several threaded rods 3 and projections 6, the described The bumps 6 and the grooves 7 correspond up and down to form the model cavity 4, the threaded rods 3 and the threaded holes 5 correspond one by one, the grooves 7 are circular in shape, and the cross-section is rectangular, and the bumps 6 are in the shape of The shape is circular, and the section is rectangular, so the model cavity 4 is circular, and the section is also rectangular.

[0013] When in use, the upper mold 2 and the lower mold 1 are in a closed state through the cooperation of several threaded rods 3 and several threaded holes 5, and the mold cavity 4 formed by the corresponding projections 6 and grooves 7 is circular, with a cross-section is a rectangle. At this point, the threaded rod 3 can be adjusted to raise or lower the upper mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap