Handle self-locking mechanism and folding joint

A technology for folding joints and handles, applied in the field of handle self-locking mechanisms and folding joints, can solve the problems of inconvenient operation, low locking pressure, and unreliable locking, etc., and achieves convenient operation, simple self-locking and unlocking processes, Stable and reliable effect of locking state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

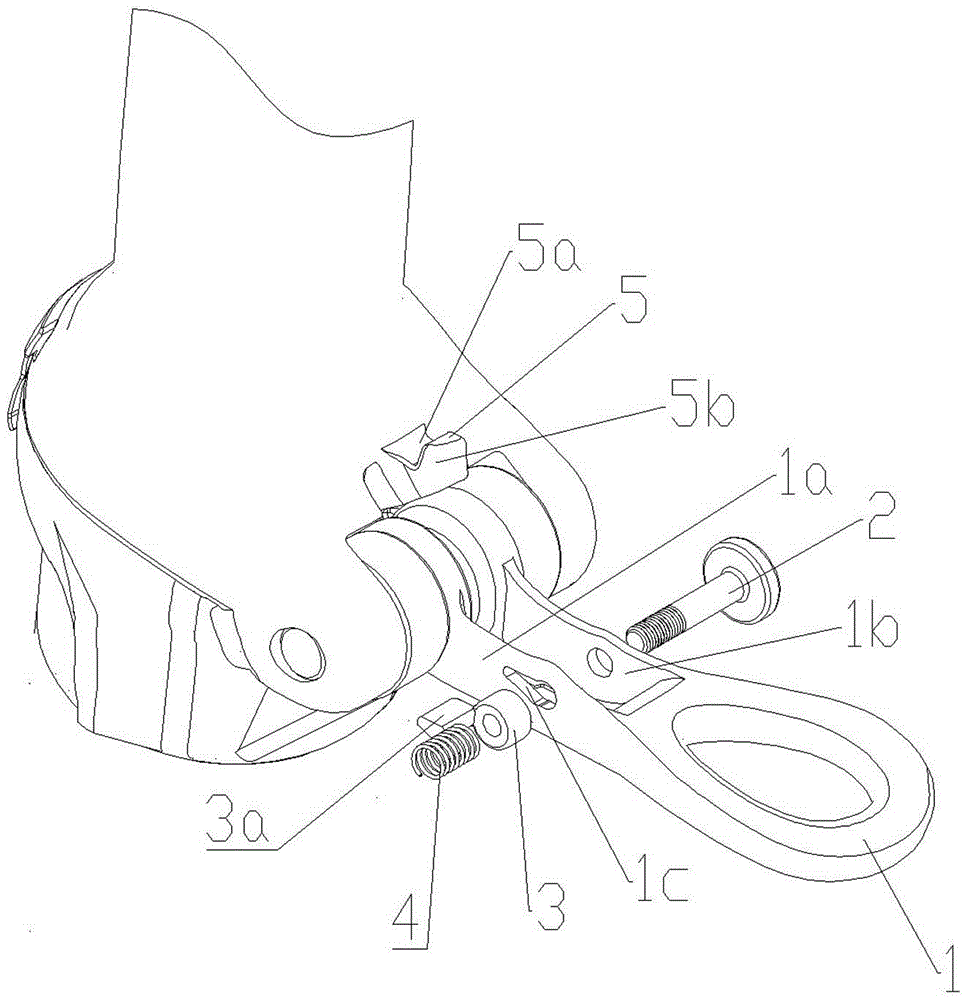

[0025] Such as figure 2 As shown, the handle self-locking mechanism proposed by the present invention includes: a handle 1, two side plates 1a, 1b symmetrically arranged in the middle of the handle 1, and locking bolts 2 that penetrate through the two side plates 1a, 1b in a movable transverse direction, and are sleeved in the lock Tighten the collar 3 and the spring 4 on the bolt 2, fix the wedge-shaped block 3a on the outer wall of one end of the collar 3, and cooperate with the locking block 5 fixed by the wedge-shaped block 3a.

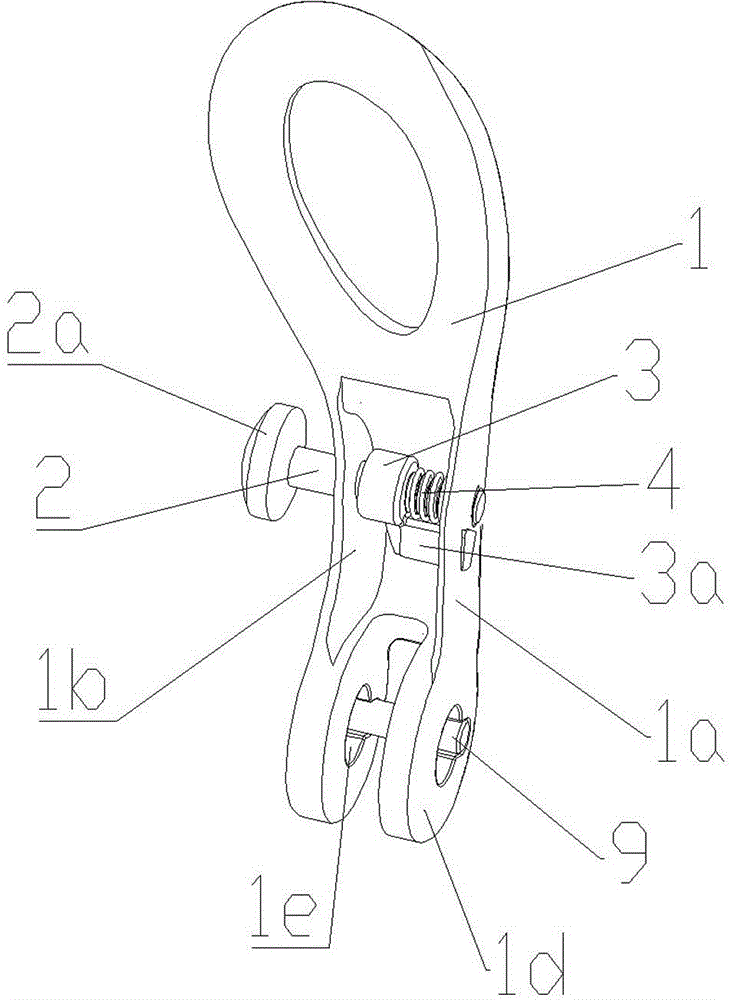

[0026] Such as image 3 As shown, one side plate 1a is provided with a limit hole 1c that matches the shape of the wedge block 3a, one end of the wedge block 3a is fixed to the collar 3, and the other end movably extends into the limit hole 1c, the wedge block 3a and the collar 3 A safety hook is formed, the collar 3 is threadedly matched with the locking bolt 2, and both ends of the spring 4 are compressed between the collar 3 and the side plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com