Limiting tool frame and limiting tool

A tooling frame and position-limiting technology, which is applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, etc., can solve the problems of inability to adapt to the general requirements of packaging for variety appearance differences, high overall cost of tooling frames, poor universality of tooling frames, etc. , to achieve the effect of preventing mutual scratches and scratches, simple structure, and not easy to damage parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to solve the problem of poor versatility of logistics tooling racks, a limited tooling rack suitable for different sizes of transportation logistics is proposed to achieve higher versatility and diversification of uses.

[0037] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

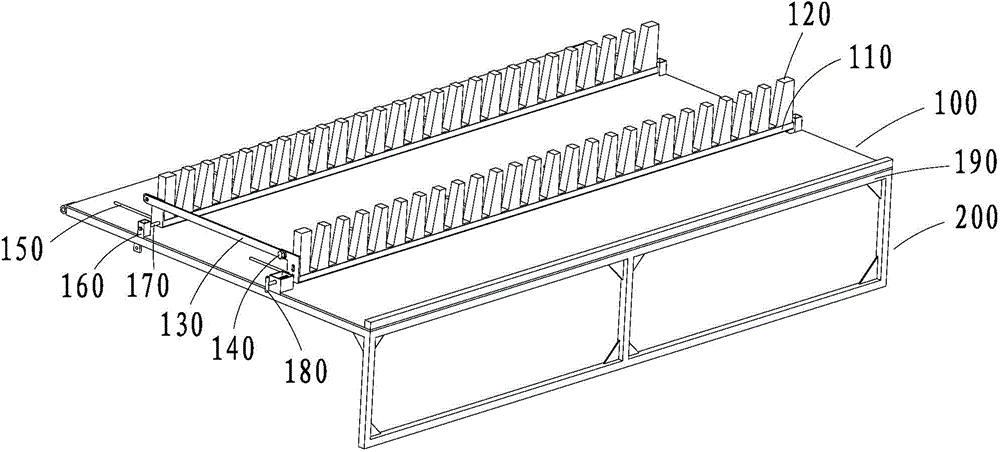

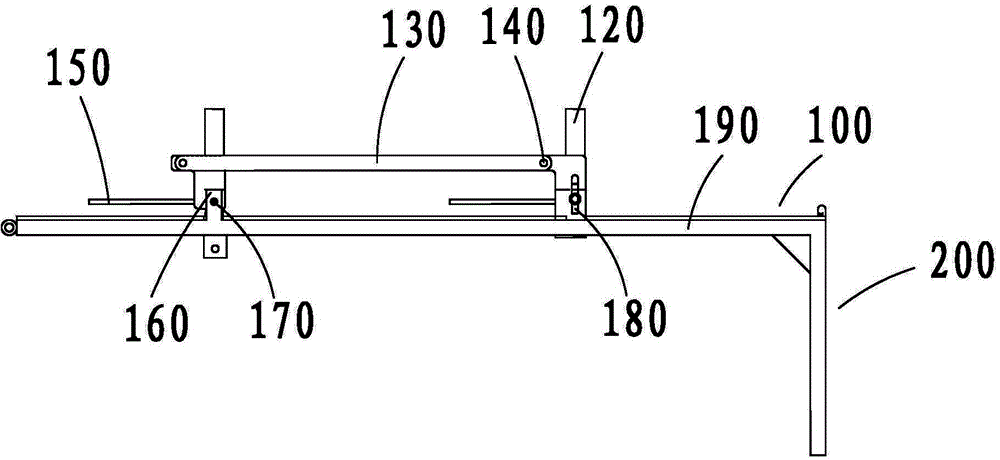

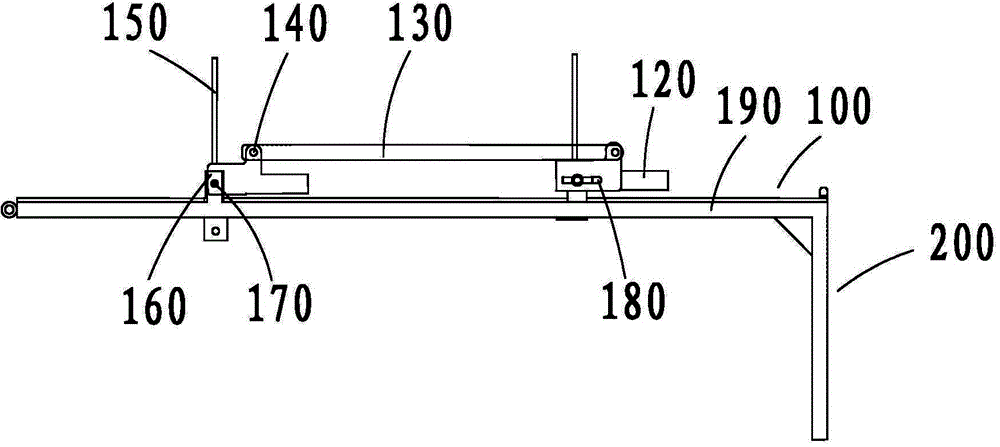

[0038] see figure 1 As shown, it is a partial three-dimensional schematic diagram of the position-limiting tool of the present invention. The position-limiting tool frame 100 includes a position-limiting bar 110 , a spacer bar 120 , a connecting rod 130 and a positioning layer 190 .

[0039] The number of limiting strips 110 is at least two, which is the same as the number of limiting spacers 120; in this embodiment, two limiting strips 110 are provided. A limiting spacer 120 is fixed on each limiting bar 110 .

[0040] The spacer bar 120 is a flat plate with continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com