Construction method of steel casing high pressure water injection to loosen soil and pull out piles

A construction method, steel casing technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as damaging the environment, limited ability to pull out piles, and difficulty in controlling tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

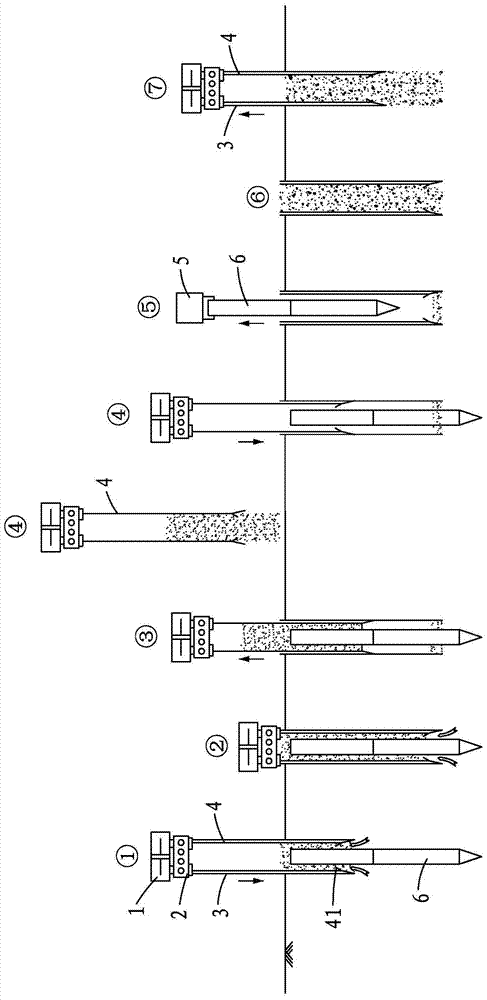

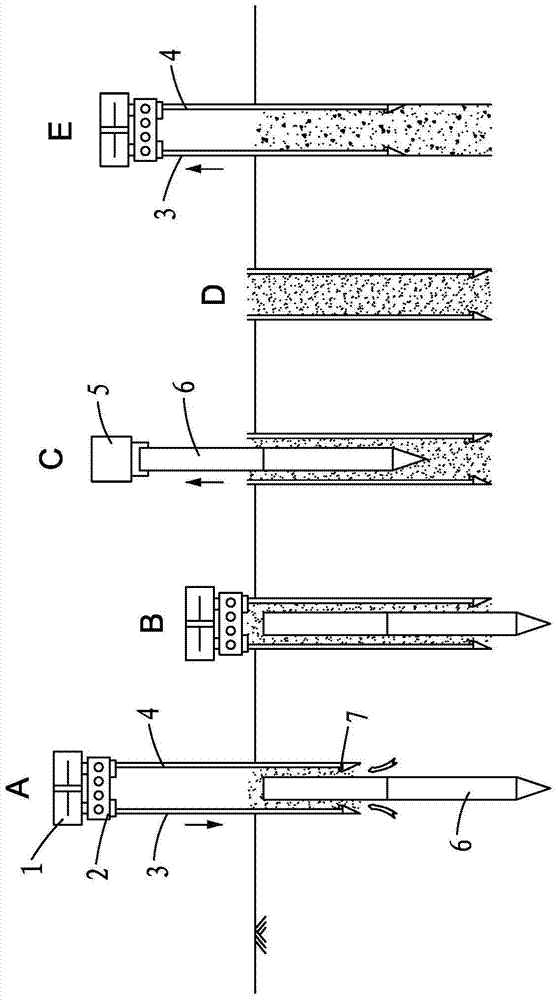

[0021] see figure 1 and image 3 , the steel casing vibrating soil extraction pile construction method comprises the following steps:

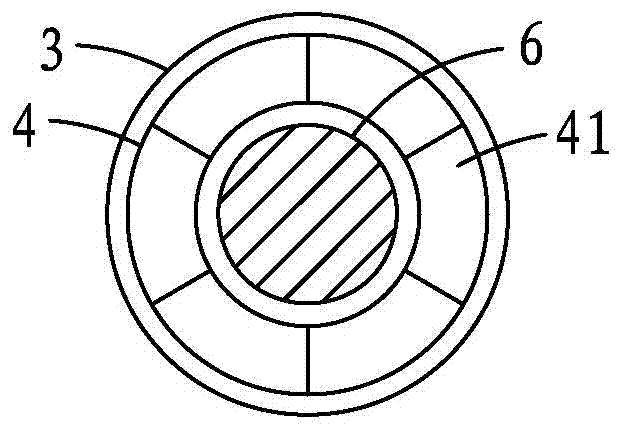

[0022] ① At the position of the old pile 6, drive the outer casing 3 and the inner casing 4 into the soil at the same time through the holder 2 under the high-frequency vibration of the high-frequency vibrating hammer 1, and the bottom of the inner casing 4 is provided with a The valve takes the soil bin 41, and the soil gradually enters the inner casing 4; the length of the outer casing 3 is within 30m, and the inner diameter is 900-1500mm.

[0023] Immersed tube soil extraction is the key to the efficiency of pile extraction. During the hole forming process, it is necessary to ensure that the outer sleeve 3 is accurately positioned at the position of the old pile 6. During the immersed tube process, the outer sleeve 3 must be vertical, and the depth of the immersed tube must meet the design requirements.

[0024] ② Outer casing 3 and inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com