A non-destructive removal device for abandoned piles in complex strata

A technology of complex strata and clearing devices, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve problems such as increased side friction resistance and difficulty in removing foundation piles, and achieve the effect of reducing the probability of damage and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

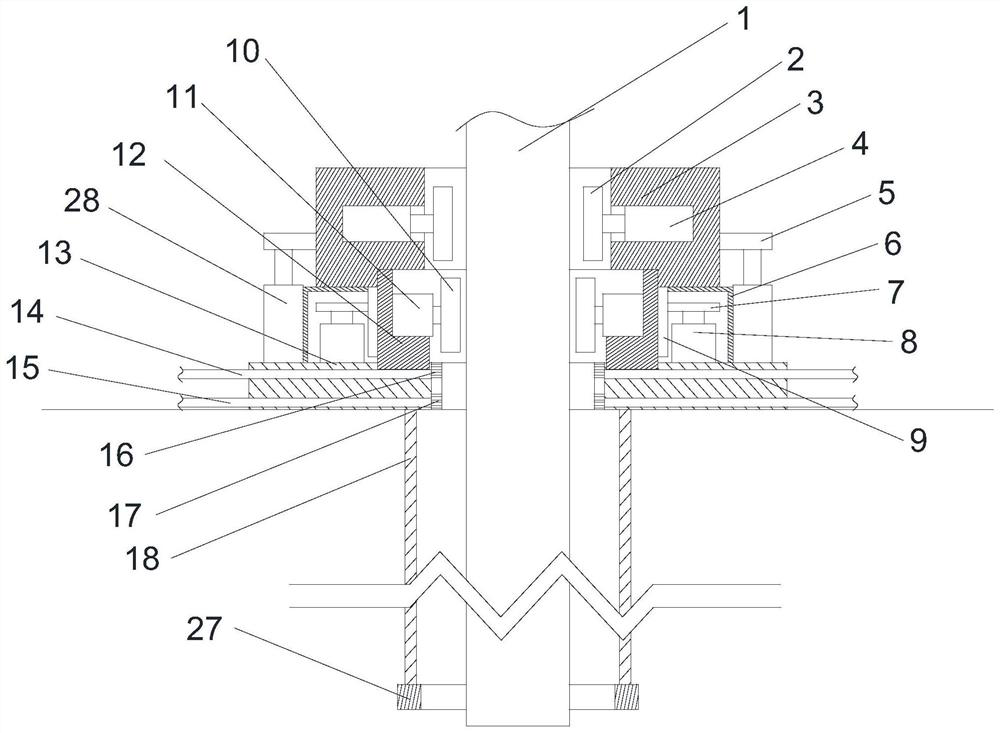

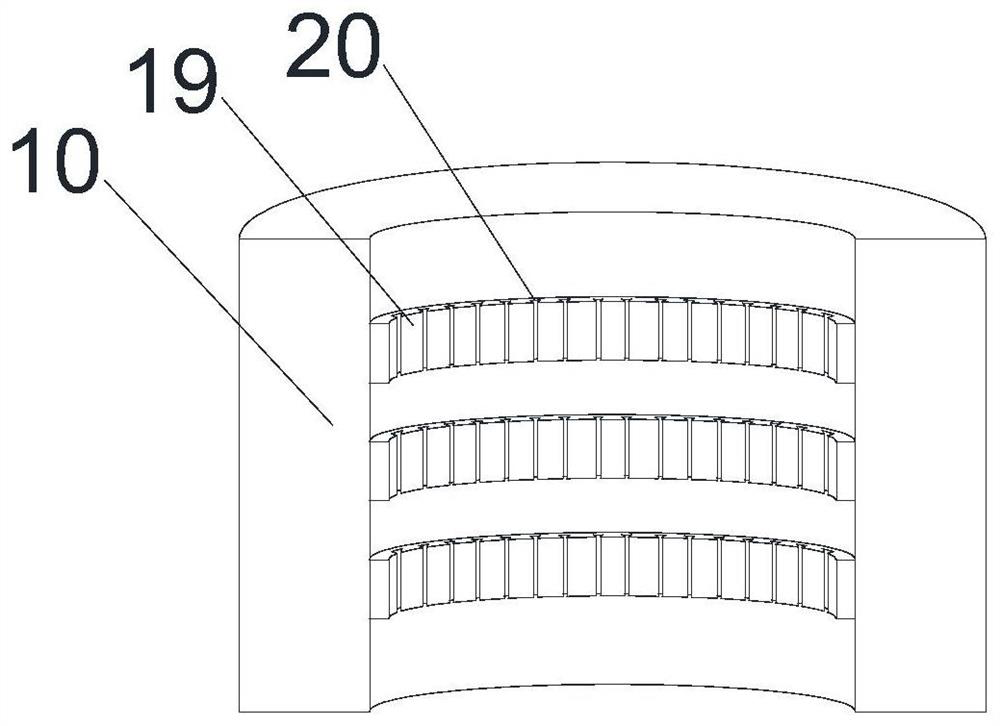

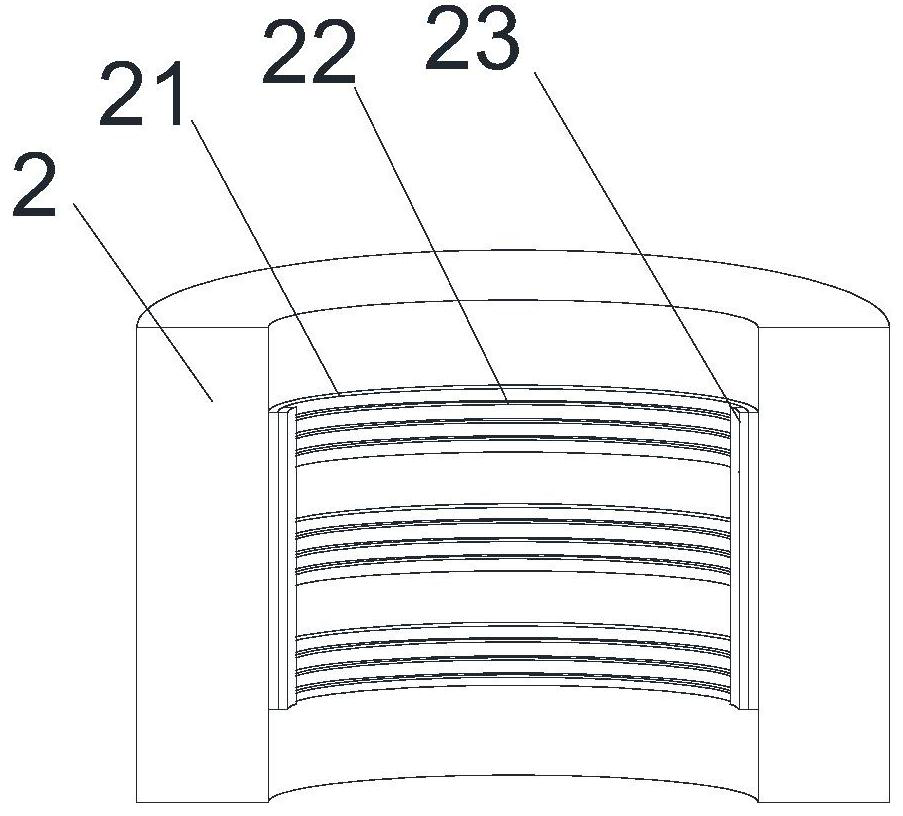

[0027] Such as Figure 1~5 As shown, this embodiment includes a sleeve 18 and a base 13 arranged at the upper end of the sleeve 18, the middle of the base 13 is provided with a bottom hole for the waste foundation pile 1 to pass through, and an upper ring seat is fixed on the base 13 3. A lower ring seat 12 coaxial with the upper ring seat 3 is provided on the lower inner wall of the upper ring seat 3, and an annular toothed belt 9 is installed on the outer peripheral wall of the lower ring seat 12. There are two through holes, and a waterproof housing 6 is provided in each of the through holes, the motor 8 is placed in the waterproof housing 6, and the output end of the motor 8 is equipped with a gear 7, and in the waterproof housing 6 The housing 6 is provided with an opening on the side wall facing the lower ring seat 12, and a part of the gear 7 passes through the opening and cooperates with the annular toothed belt 9, along the circumferential direction of the upper ring ...

Embodiment 2

[0033] Such as Figure 1~5 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of spray heads 24 are uniformly arranged on the inner circumferential wall of the bottom hole along the circumferential direction of the bottom hole, and two groups of spray holes are respectively opened on the spray heads 24 16 and two groups of backflow holes 17, and the horizontal height of the spray hole 16 is greater than the horizontal height of the backflow hole 17, and a water storage chamber 25 and a sedimentation chamber 26, which are independent of each other, are respectively arranged inside the nozzle 24. One group of spray holes 16 communicates with the water storage chamber 25, two groups of return holes 17 communicate with the sedimentation chamber 26, the water inlet pipe 14 runs through the outer wall of the base 13 and communicates with the water storage chamber 25, and the outlet pipe 15 runs through the base 13 The outer side wall of the tube communicates wit...

Embodiment 3

[0037] Such as Figure 1~5 As shown, on the basis of Embodiment 1, the present embodiment is also provided with a drill tube 27 at the lower end of the casing 18, the outer diameter of the drill tube 27 is greater than the outer diameter of the casing 18, and the drill tube 27 The inner diameter is smaller than the inner diameter of the sleeve 18 . When the outer diameter of the drill pipe 27 is greater than the outer diameter of the casing 18, and the inner diameter of the drill pipe 27 is smaller than the inner diameter of the casing 18, so that the drill pipe 27 can expand the casing pipe 18 when drilling and moving down after cutting into the soil layer. The gap ensures that the air enters the gap while ensuring the smooth progress of the water injection process.

[0038] The main function of the sleeve 18 is to separate the foundation pile 1 from the surrounding soil layer. During the operation, the selection of the sleeve 18 is different according to the different topog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com