Assembly type green building system and construction method

A green building and prefabricated technology, which is applied in building structure, construction, building materials, etc., can solve the problems of unstructured supporting external maintenance materials, heavy board body, and unsatisfactory energy-saving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

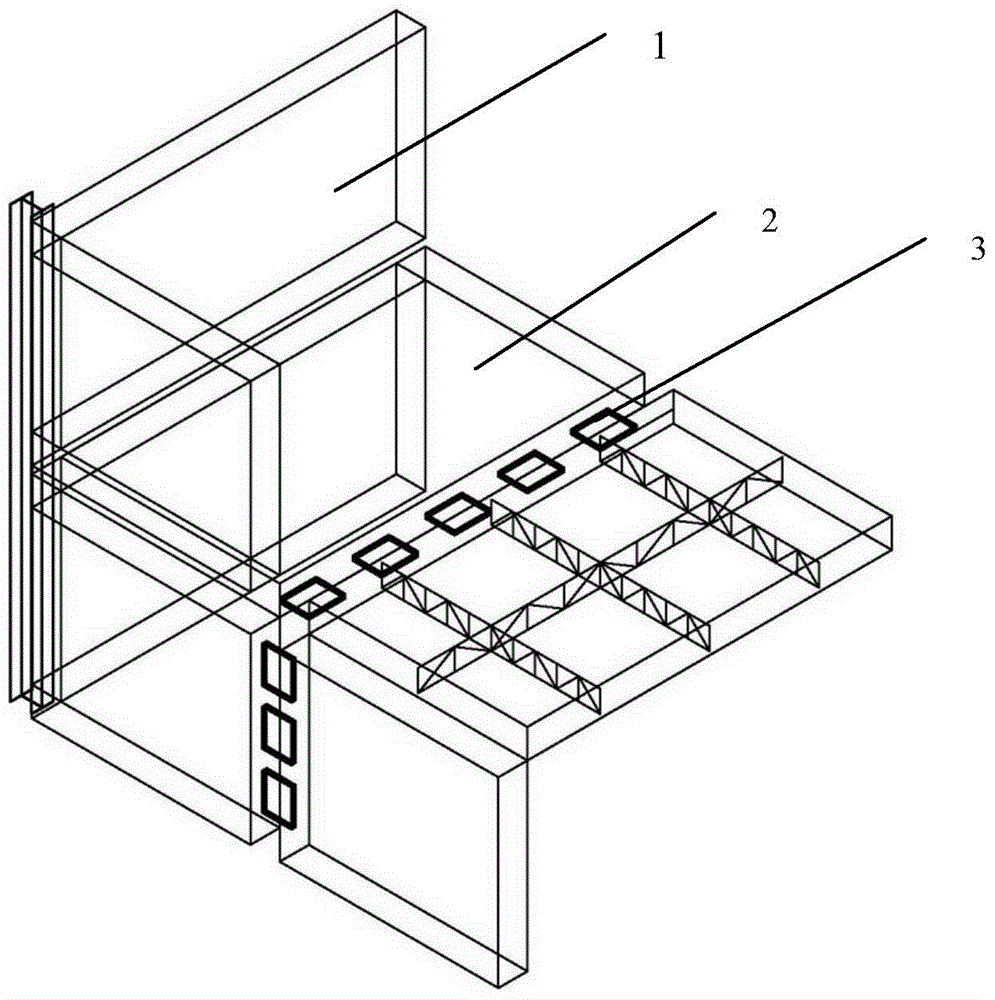

[0043] like figure 1 As shown, the prefabricated green building system of the present invention is to assemble and fix the load-bearing wall panels 1 or interior and exterior wall panels 1 with the characteristics of green buildings with the floor 2 and roof panels through the connector 3, and then fill the decorative sealing material 4 to form a building structure system with composite beams or composite columns.

[0044] Wherein, the connecting piece 3 includes: a plug-in connecting piece or a bolted connecting piece.

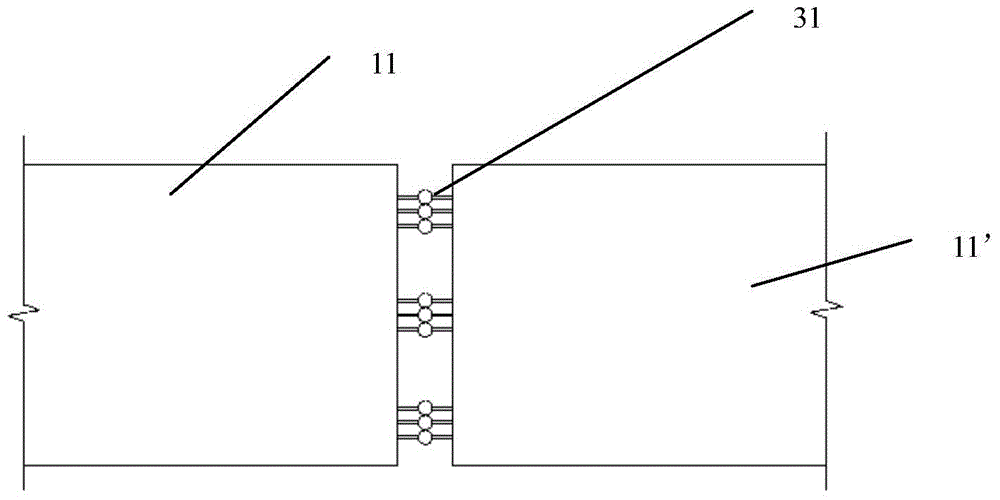

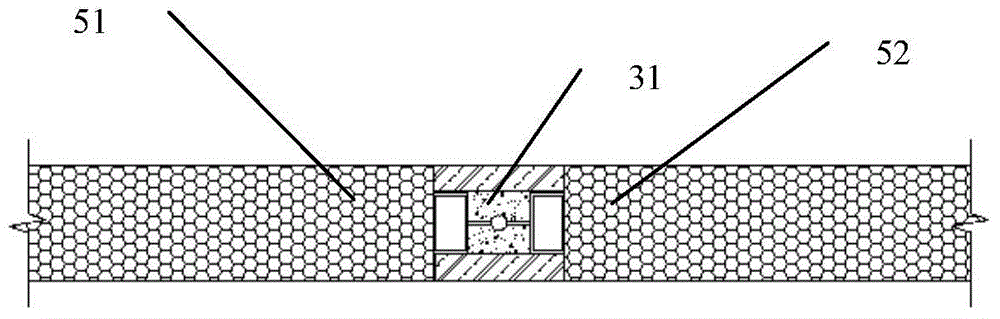

[0045] like Figure 2-1 , 2-2 , 2-3, the load-bearing exterior wall panels or interior wall panels described in the present invention are two green building panels 11, 11' assembled and fixed together by plug connectors 31 or 32; and The gaps between the plates 11 and 11' are filled with decorative sealing material 4 to form a load...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap