The method of automatically adjusting the rb target value of the calorific value correction coefficient in thermal power generating units

A technology for thermal power generation units and correction coefficients, which is applied in steam generation, control systems, lighting and heating equipment, etc., and can solve problems such as inability to reflect changes in fuel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

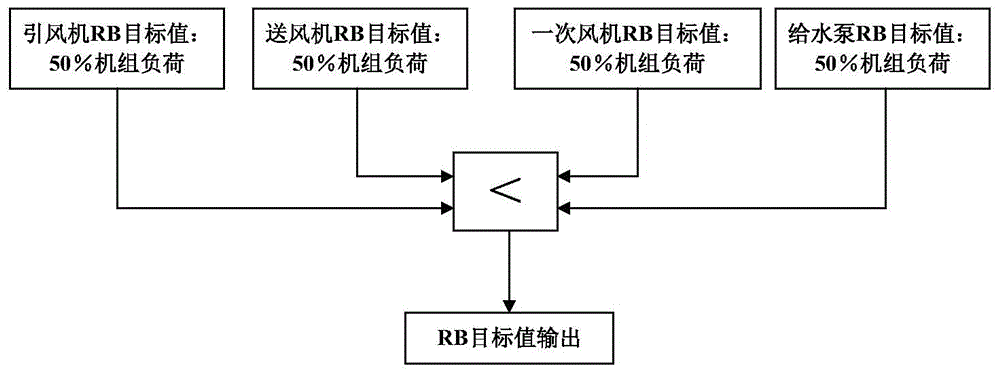

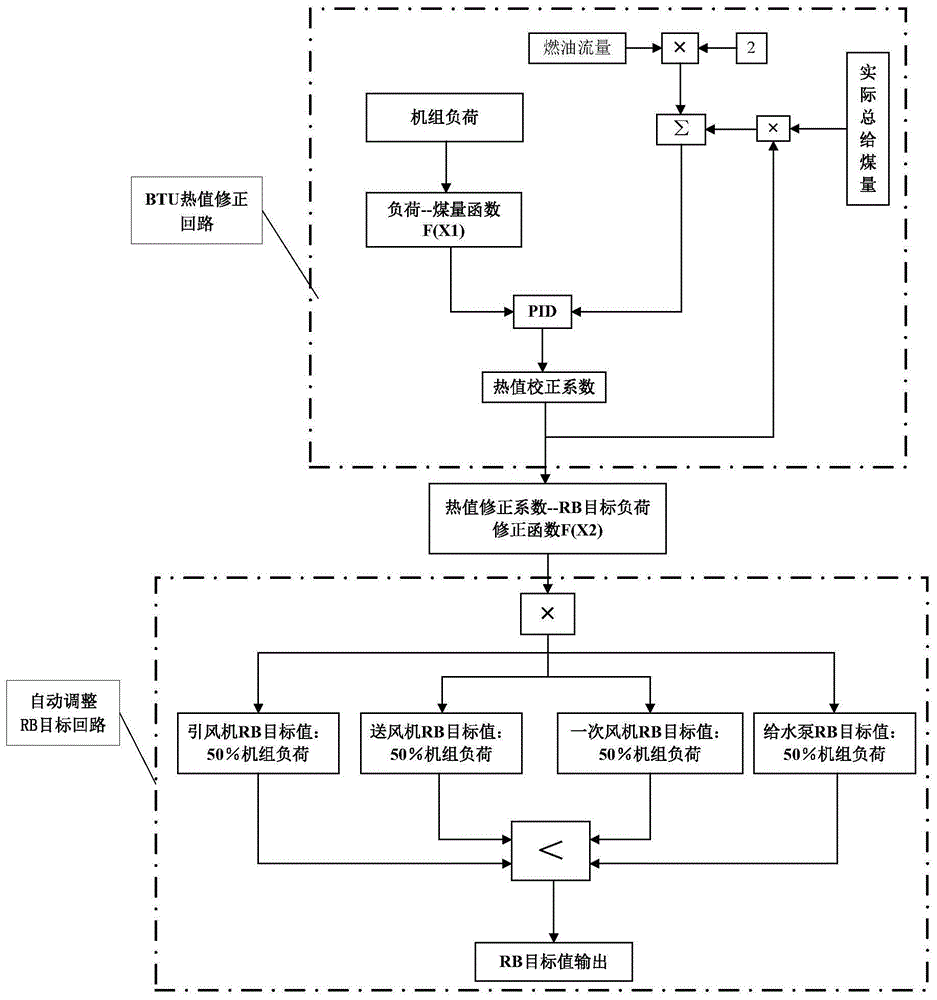

[0034] The realization method of this control scheme is composed of three parts: BTU calorific value correction loop, calorific value correction coefficient --- RB target load correction function, and automatic adjustment RB target loop.

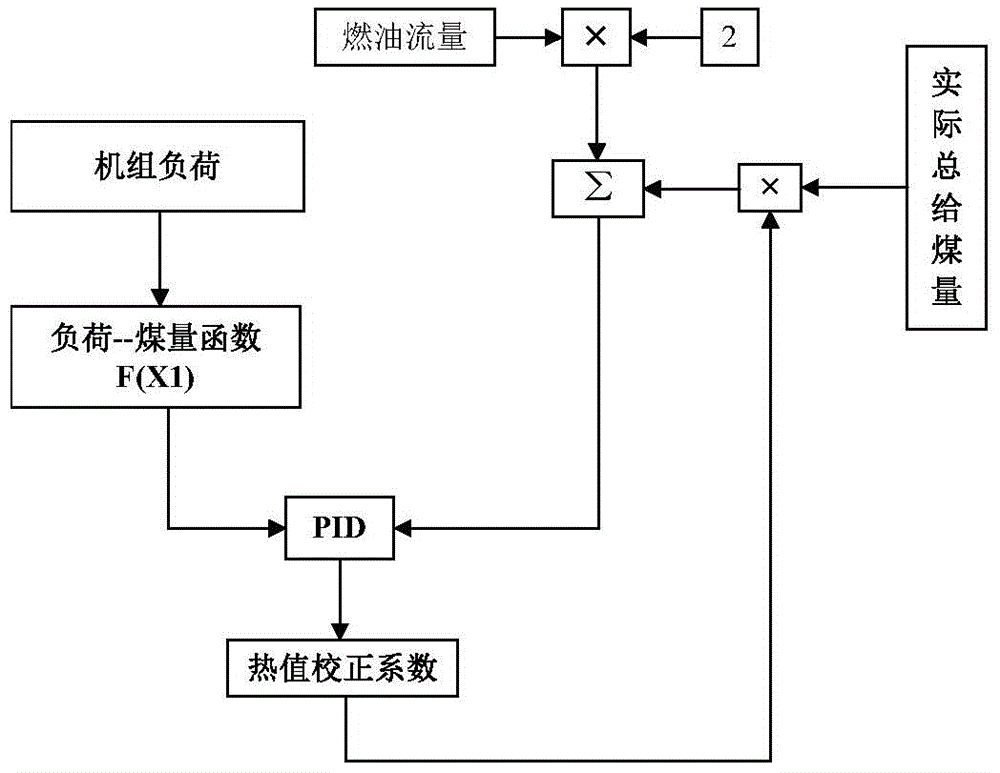

[0035] The first part is the BTU calorific value correction circuit. From the unit load analog value, the coal quantity function F(X1) corresponding to the unit load, the PID controller, the actual total coal supply value (obtained by adding the coal supply feedback analog quantity points of each coal feeder), The blocks of the multiplication algorithm are connected through logical control configuration.

[0036] The unit load analog value is obtained through the load-coal function F(X1) to obtain the design coal quantity corresponding to the current load, which is used as the set value of the PID controller; the actual total coal supply of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com