Straw returning seeder

A planter and straw technology, which is applied to the field of straw returning planters, can solve the problems of affecting sowing and fertilization, being unsatisfactory, and not being able to directly pulverize and pulverize, and achieve ideal ditching effect and good pulverizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

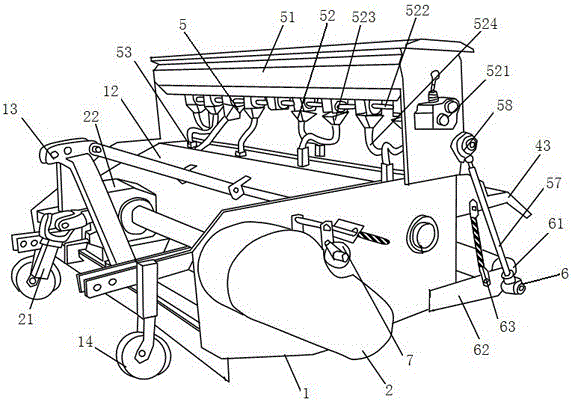

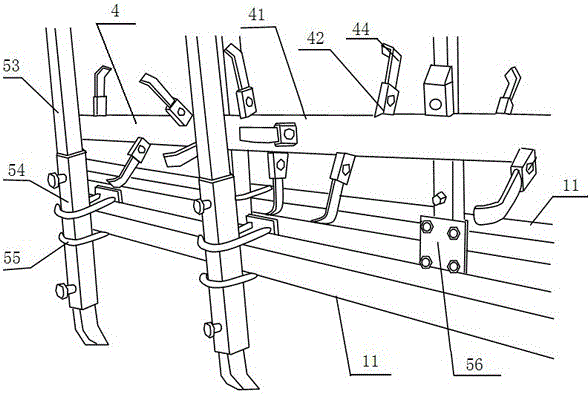

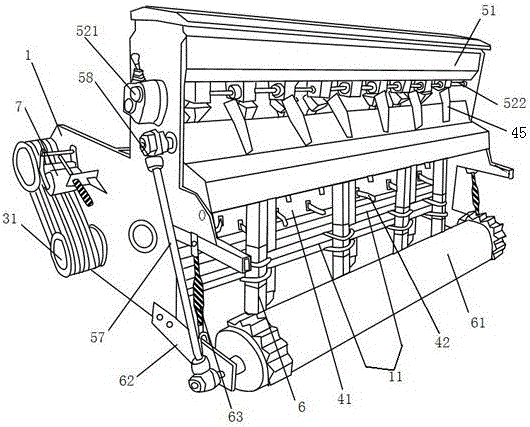

[0021] As shown in Figures 1, 2, and 3, a straw returning seeder is composed of a body 1, a main transmission assembly 2 installed on the body, a stubble removal assembly, a grass cleaning assembly 4, a sowing fertilizer assembly 5, and a soil covering assembly 6; The main transmission assembly 2 is connected to the power shaft of the stubble removal assembly, and the power shaft of the stubble removal assembly is connected to the transmission shaft of the grass clearing assembly 4; the output shaft of the covering soil assembly 6 is connected to the input shaft of the sowing fertilizer assembly 5; the stubble removal assembly includes a power shaft 31. The Y-shaped stubble cutters and kneading cutters installed on the body are evenly spaced on the power shaft; The grass-distributing board 43 on the top; the sowing fertilizer assembly 5 includes a seed fertilizer box 51, a seed fertilizer arrangement 52, and a ditch opener 53 connected in sequence; the ditch openers 53 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com