Ditching system suitable for surface layer of natural grassland of high-altitude cold region

A technology in cold area and surface layer, applied in the direction of excavation/covering of trenches, application, planting methods, etc., to achieve the effects of great ecological protection and construction, good trenching effect and high uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

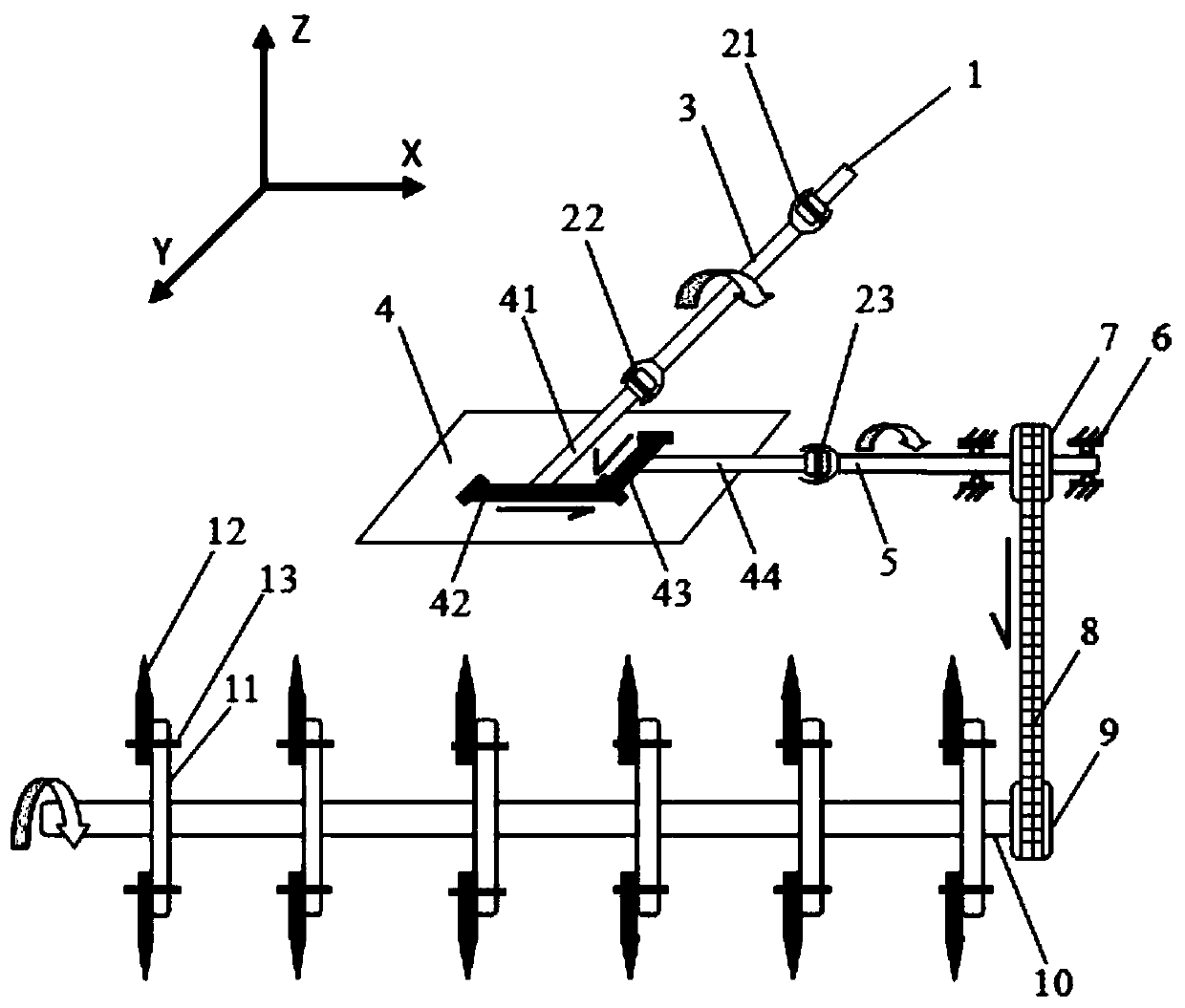

[0033] Such as figure 1 As shown, the ditching system of this embodiment includes a power output port 1, a first steering knuckle 21, a power output shaft 3, a second steering knuckle 22, a reversing gearbox 4, a third steering knuckle 23, and a power transmission shaft 5 , Rolling bearing 6, driving sprocket 7, double chain 8, driven sprocket 9, cutterhead installation shaft 10, flange cutterhead 11, ditching knife 12, bolt 13. The power output port 1 is connected to the tractor diesel engine, and the power and motion are transmitted to the power output shaft 3 through the first steering knuckle 21, and the power output shaft 3 is connected to the reversing gearbox 4 through the second steering knuckle 22, and the power and motion Transfer to the reverse gearbox 4; the reverse gearbox 4 includes an input shaft 41, a driving bevel gear 42, a driven bevel gear 43, and an output shaft 44, and the input shaft 41 is connected with the power output shaft 3 through the second steeri...

Embodiment 2

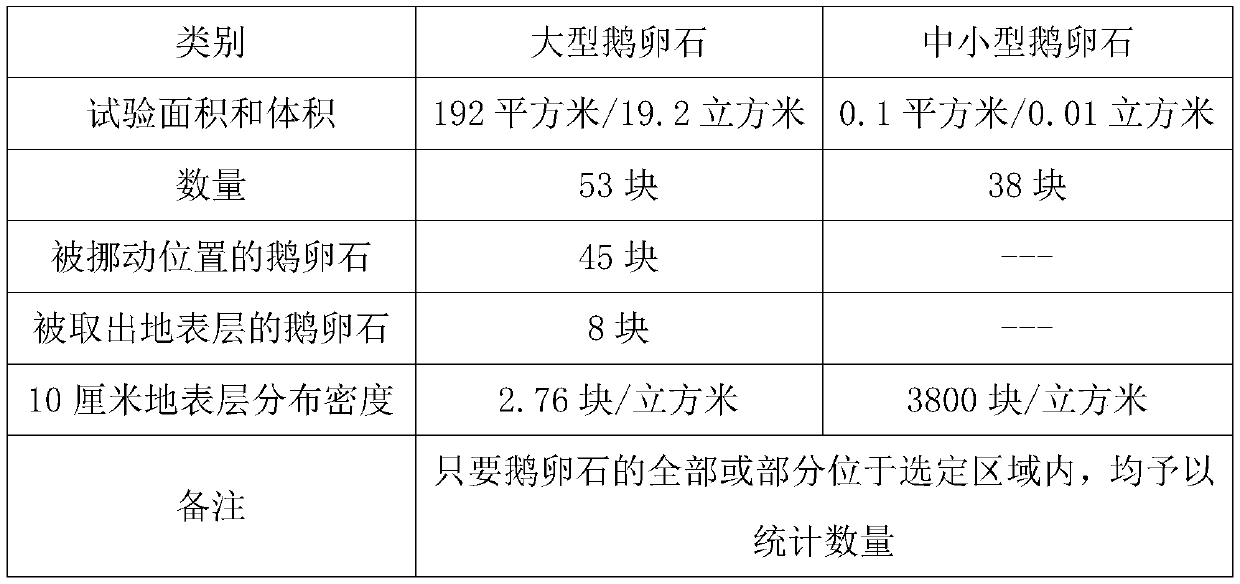

[0048] This embodiment is to carry out the durability test on the ditching system, and is to check the continuous working ability of the ditching system. The test process is as follows: the ditching system of this embodiment is installed on a certain type of tractor (the maximum output speed of the tractor diesel engine is 2200 rpm ), driven by a tractor, the ditching system ditched for 200 kilometers, randomly selected 100 points in this interval to measure the ditching depth, calculated the average ditching depth and the ditching depth was between 30 and 70 mm to reflect the ditching effect of the ditching system; in the working area of the ditching system, arbitrarily select a length of 100 meters, and count the number of large pebbles with an average diameter of more than 30 cm; select any one of the ditches , the length is selected as 1 meter, and an area of 5 cm on each side of the ditch and a depth of 10 cm is selected, and the number of small and medium-sized pebble...

Embodiment 3

[0063] This embodiment is basically the same as Embodiment 2, except that the transmission ratio of the ditching system is set to 3:1, and the distribution ratio of the transmission ratio is as follows: the reversing gearbox 4 is a speed reducer, and the transmission ratio is set to 2:1, The number of teeth of the driving bevel gear 42 and the driven bevel gear 43 are 30 and 60 respectively; the chain transmission mechanism composed of the driving sprocket 7, the double chain 8 and the driven sprocket 9 is a reducer, and the transmission ratio is set to 1.5:1. The number of teeth of sprocket 7 and driven sprocket 9 are 40 and 60 respectively. Normally, the maximum rotational speed of the tractor diesel engine does not exceed 2400 rpm, and this embodiment ensures that the maximum rotational speed of the ditching knife 12 does not exceed 800 rpm. The test results are shown in Table 9 to Table 12:

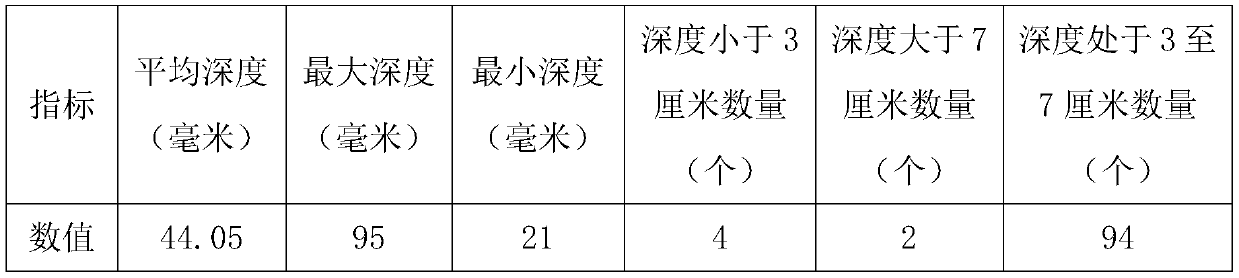

[0064] Table 9 Statistical Table of Ditching Effect

[0065]

[0066] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com