Rotating grass trimmer

A lawnmower and rotary technology, which is applied in the direction of lawn mowers, harvesters, agricultural machinery and implements, etc., can solve problems such as waste, not enough, and can only be turned on and off multiple times, so as to achieve intelligent process and solve waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

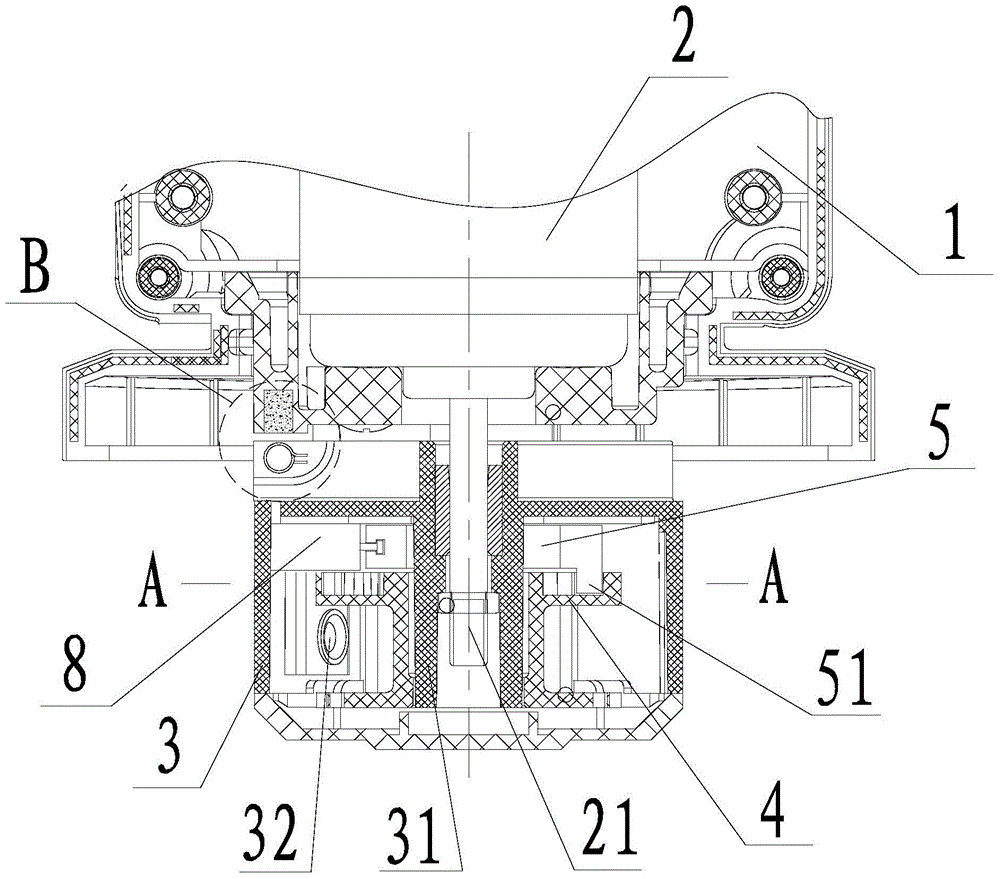

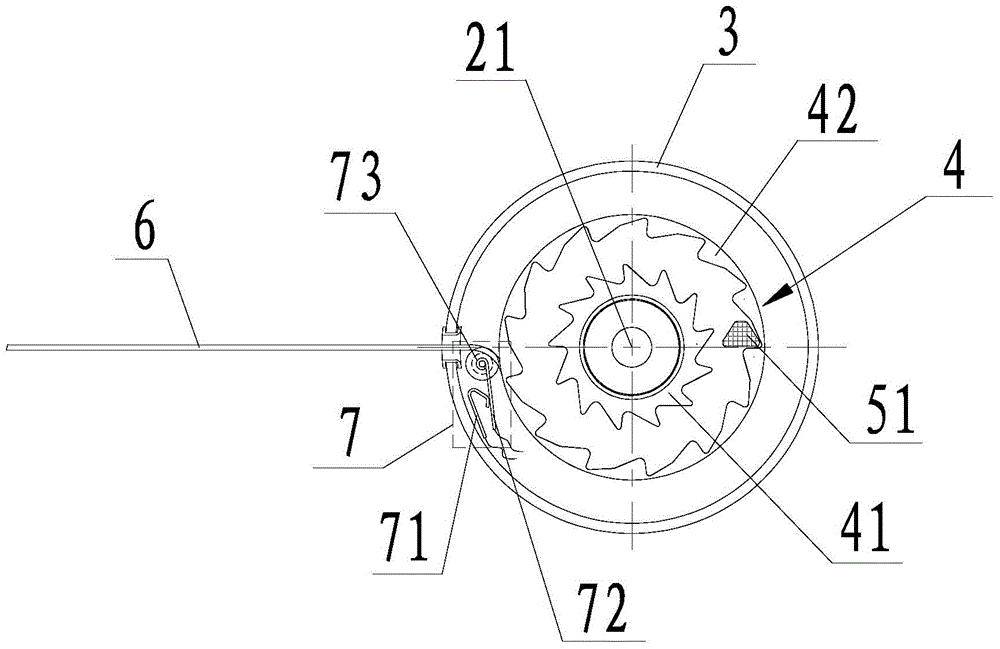

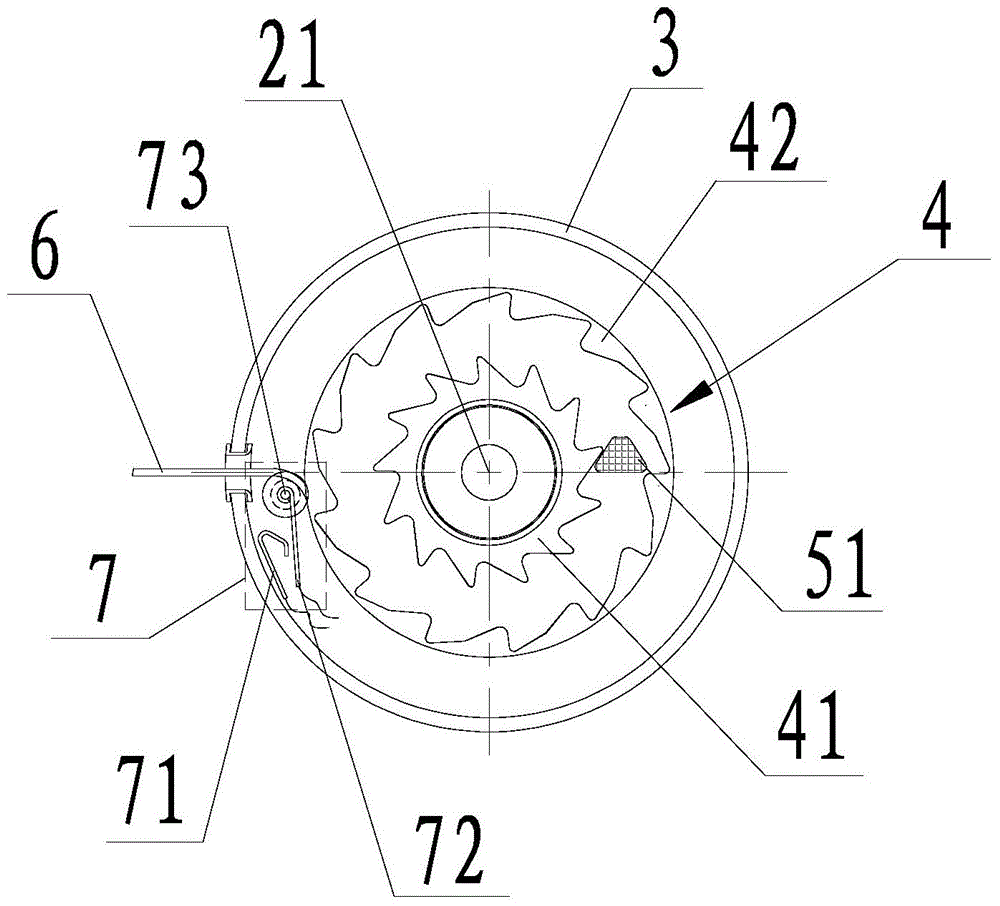

[0026] Preferred implementations of the rotary mower of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] attached Figure 1-4 It shows the structure of the rotary mower of the present invention, which includes a housing 1 and a motor 2 arranged in the housing 1. The motor 2 has an output shaft 21, and the output shaft 21 is connected to the wire box 3 in transmission, and the wire box 3 is fixed inside A positioning post 31 is provided, and the output shaft 21 can be connected with the positioning post 31 through interference fit. The wire box 3 is provided with a winding reel 4 and a wire release fork 5, wherein the reel 4 is movably sleeved on the positioning column 31, and the top of the reel 4 is provided with a concentric inner ratchet gear 41 and an outer ratchet gear. Ring gear 42, the tooth shape of the two is preferably unified tooth shape; Offer sliding groove on the pay-off shift fork 5, to be able to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com