Wok for making tea

A technology for wok and tea, which is applied in tea treatment before extraction, etc. It can solve the problems of insufficient quality of tea leaves, failure to improve the effect of greening and straightening, and achieve the effect of maintaining color and fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The invention will be further described below in conjunction with specific embodiments.

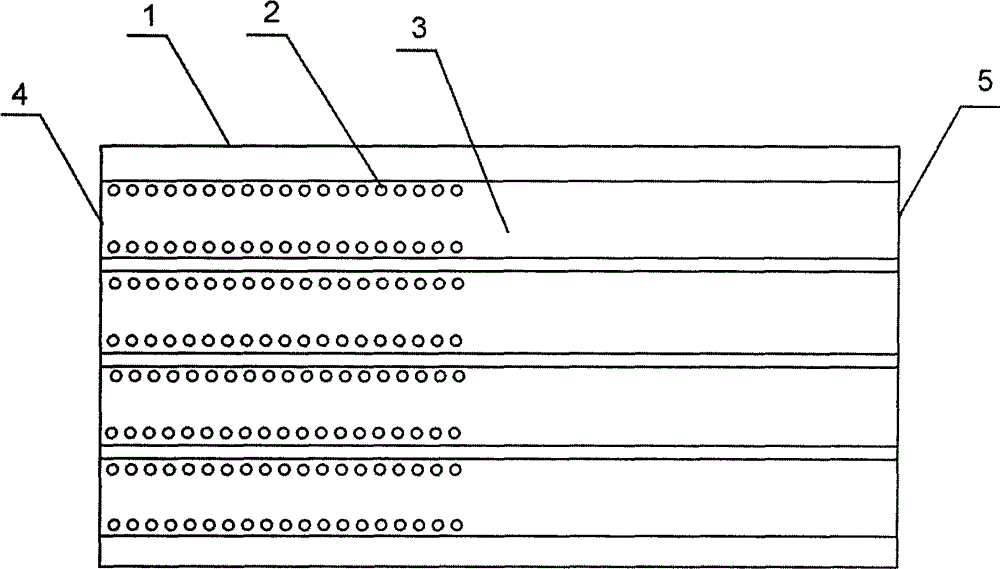

[0009] refer to figure 1 , the wok for making tea comprises a body 1 provided with a groove 3, and a punching hole is opened on the bottom or side wall (or on the bottom and the side wall) of the groove 3 on the side of the tea inlet end 4 of the body 1. The hole 2 is not punched on the groove 3 side of the body 1 near the tea outlet end 5 . That is, the left half of the bottom or the side wall (or the bottom and the side wall) of the groove 3 has a punching hole, and the right half does not have a punching hole.

[0010] When in use, when the tea leaves enter the groove 3 from the tea inlet end 4, the greening and stripping start to be carried out at the same time. The punching hole 2 on the groove body can make the infrared wave pass through the punching hole 2 and directly contact the tea leaves, which is easily absorbed by the tea leaves and improves the quality of the tea lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com