Wheel pressure balance mechanism for crane cab

A technology of balancing mechanism and crane, which is applied in the direction of traveling mechanism, load hanging components, transportation and packaging, etc. It can solve the problems of fast friction of the guide rail group, large wheel pressure, deformation of the guide rail group, etc., and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

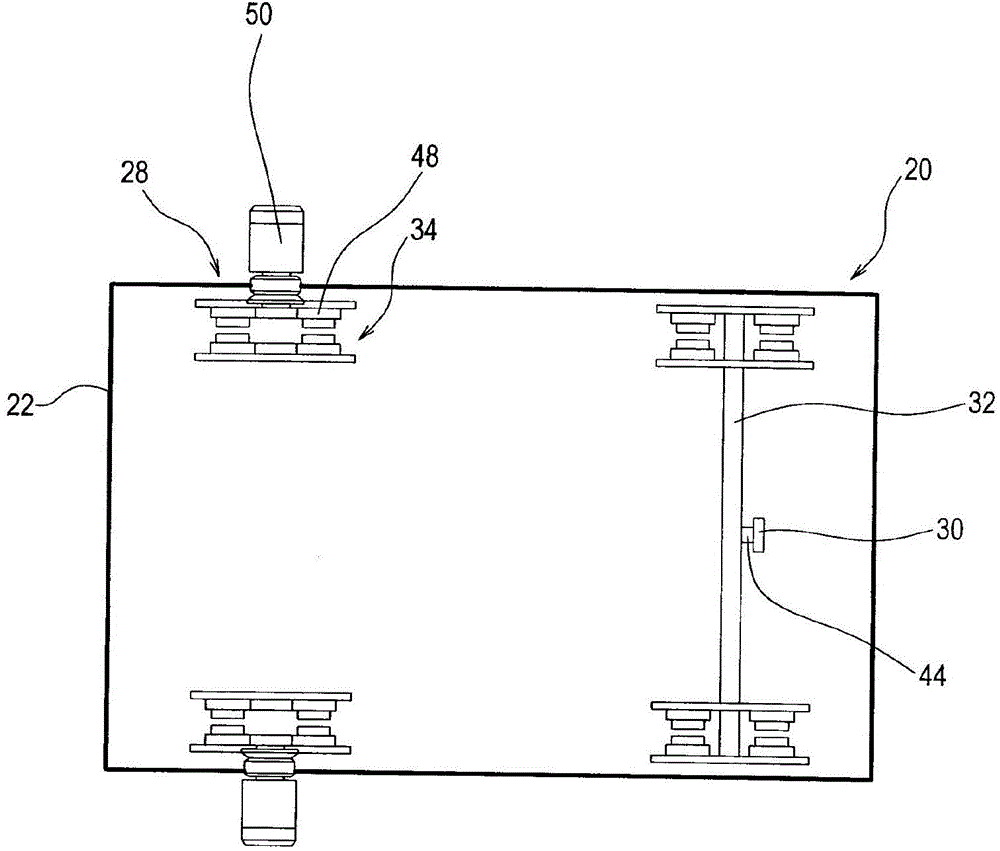

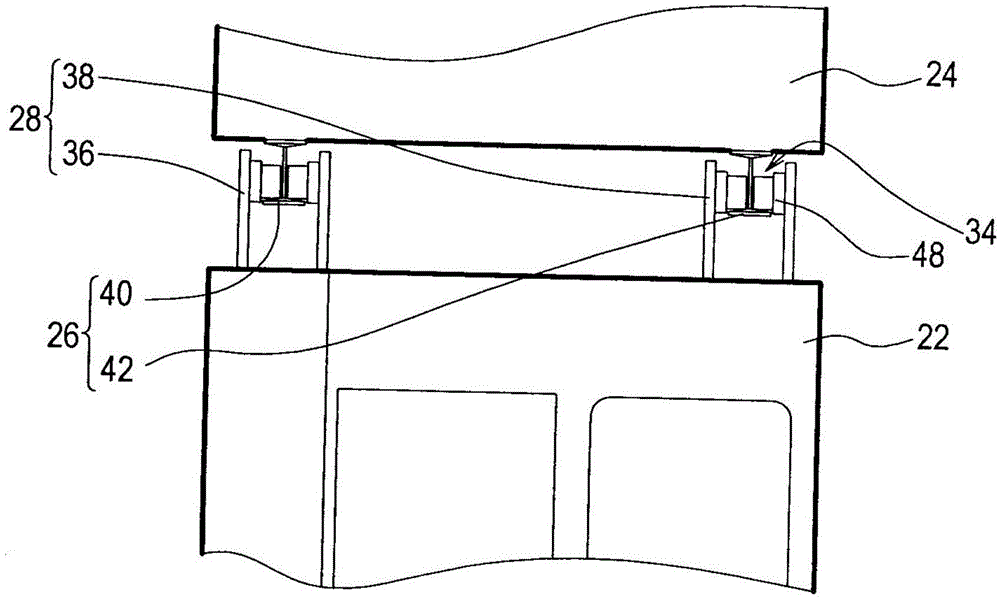

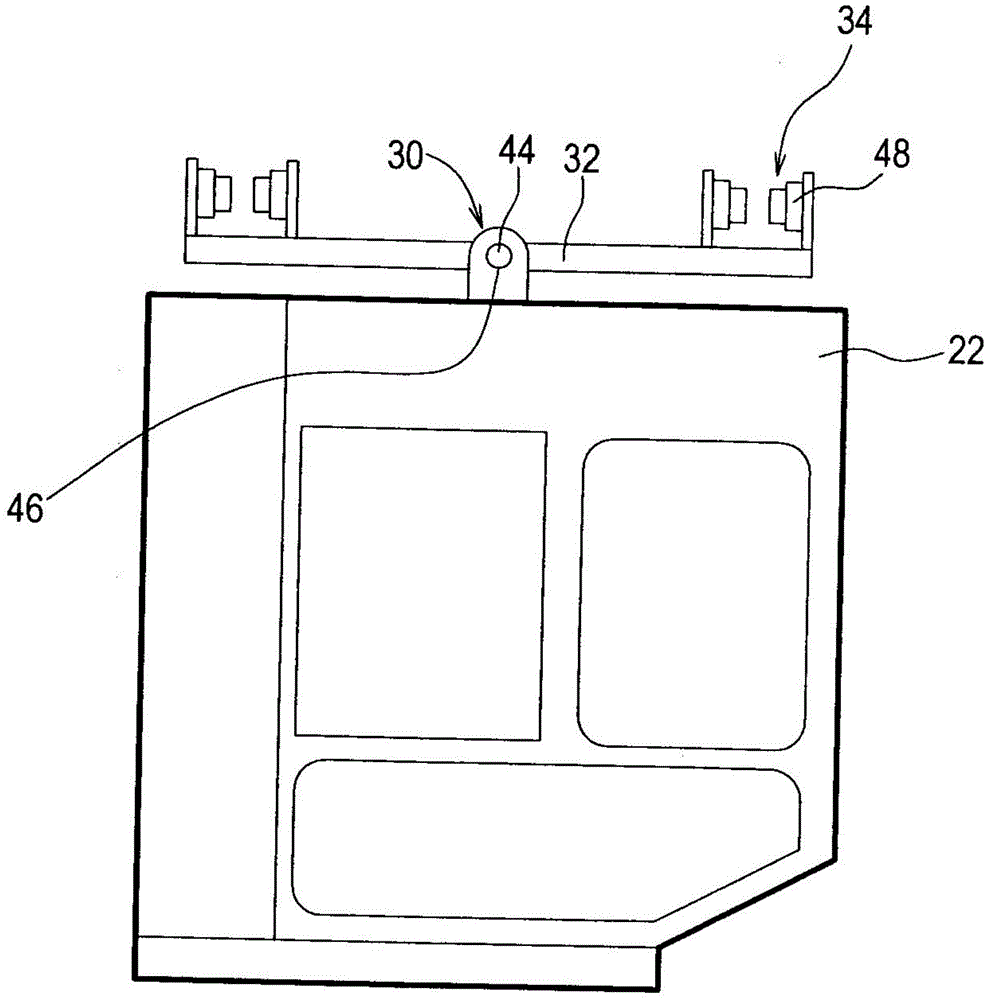

[0011] The wheel pressure balance mechanism 20 of the crane cab is applied to a guide rail set 26 for suspending a crane cab 22 below a crane girder 24 . Wherein the crane cab 22 can be configured on a ship unloader or the like. The wheel pressure balancing mechanism 20 of the crane cab includes a plurality of wheel set fixing seats 28 , a balance bar fixing seat 30 , a first balance bar 32 and a plurality of wheel sets 34 . The wheel set fixing base 28 and the balance bar fixing base 30 are all arranged on the top of the crane cab 22, and the wheel set fixing base 28 corresponds to the guide rail set 26, wherein the wheel set fixing base 28 includes a first wheel set fixing base 36 and a first wheel set fixing base 36. The two wheel set fixing seats 38, and the guide rail set 26 include a first guide rail 40 and a second guide rail 42 parallel to each other. The first wheel set fixing seat 36 and the second wheel set fixing seat 38 correspond to the first guide rail 40 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com