Marine jib crane luffing structure

A crane and luffing mechanism technology, which is applied in the field of luffing structure of marine jib cranes, can solve the problems of steel rope wear, can not meet the needs of use, low efficiency of hydraulic cranes, etc., and achieves the effect of avoiding excessive wear and saving labor in the adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

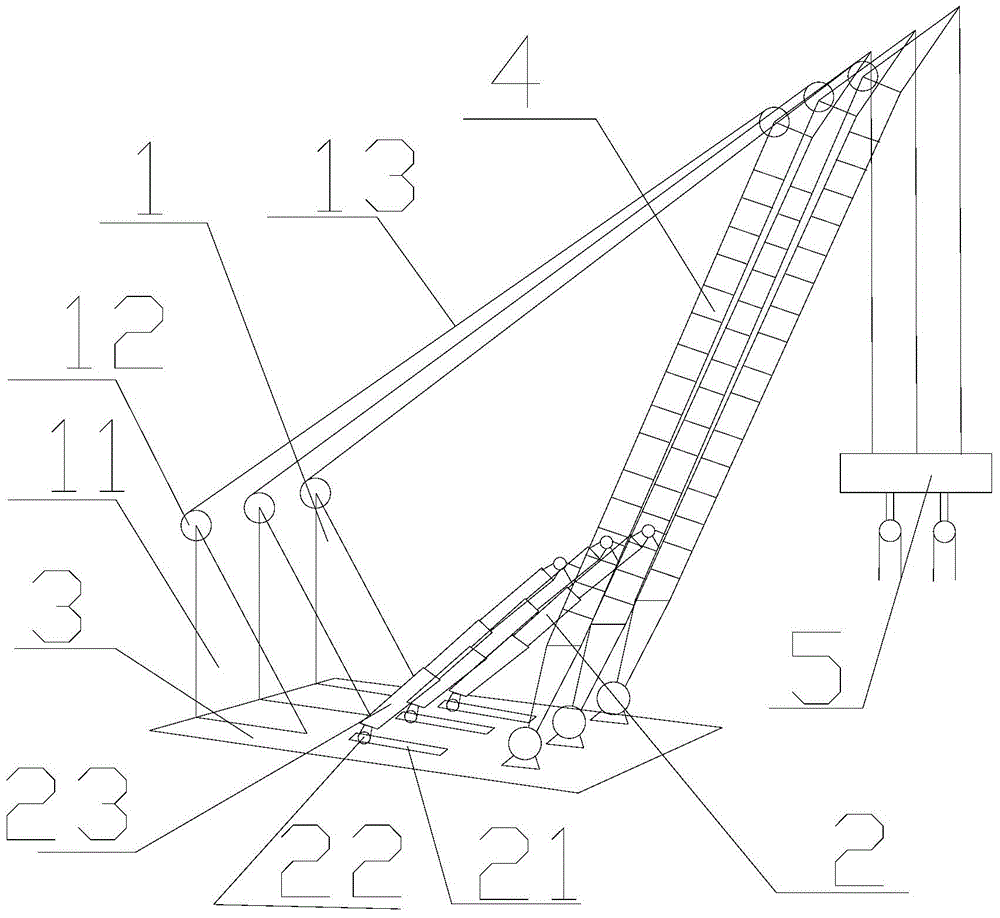

[0013] Such as figure 1 As shown, a luffing structure of a marine jib crane includes a steel rope luffing mechanism 1 and a telescopic cylinder luffing mechanism 2; the steel rope luffing mechanism 1 includes: a tripod 11, a reel 12 and a steel rope 13 The telescopic cylinder luffing mechanism 2 includes: a bottom sliding mechanism 21, a rotating shaft 22 and a telescopic oil cylinder 23; Rotate at any angle on the horizontal plane, change the angle, the rear end is provided with three tripods 11, the top of each tripod 11 is provided with a reel 12 powered by a motor, the steel rope 13 on the reel 12 and the arm The top of the frame 4 is connected and fixed, so that when the reel 12 is working, the top of the boom 4 can be controlled and the angle of the boom 4 in the horizontal plane can be adjusted by retracting and releasing the steel rope 13. The middle part of the platform 3 is provided with three bottom sliding mechanisms 21, and the bottom sliding mechanism 21 can adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com