Rail type multi-leaf door with automatic door locking, unlocking, opening and closing functions

A technology for automatic opening and closing and door functions, which is applied in the layout of wings, building fastening devices, buildings, etc., can solve the problems of low safety factor, short life of accessories, low safety, etc., to achieve easy control and operation, taking into account Good aesthetics and anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, structure of the present invention will be further described:

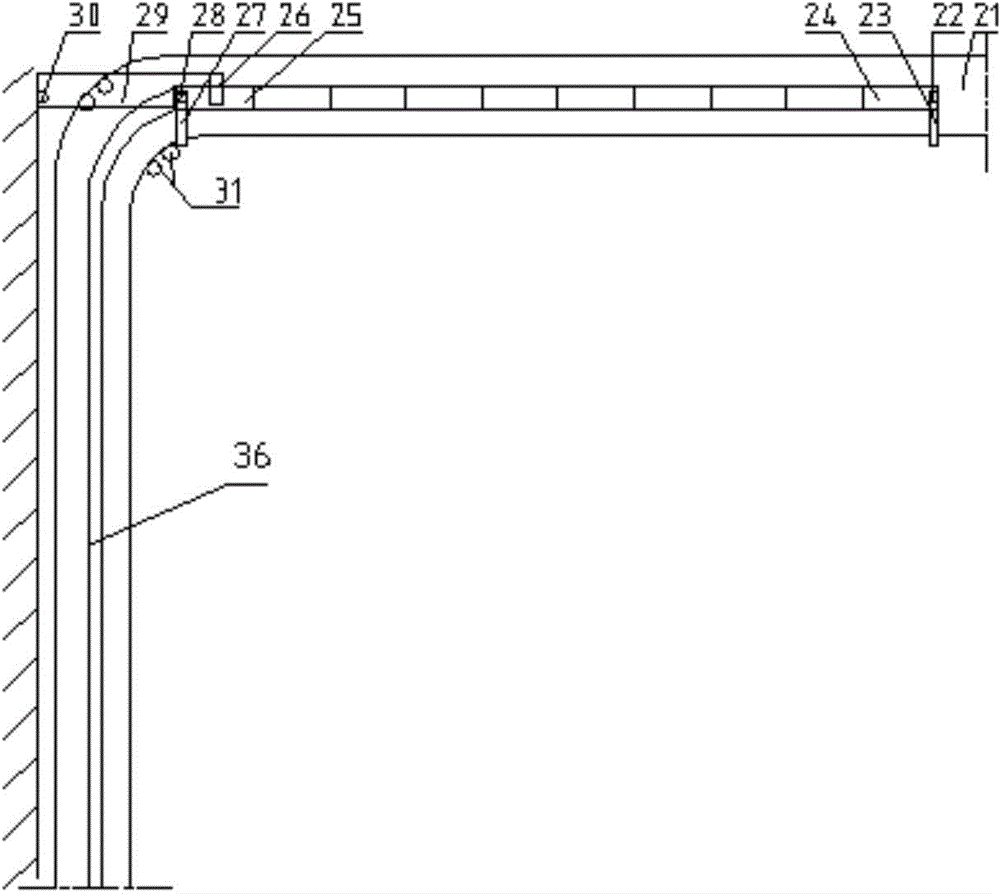

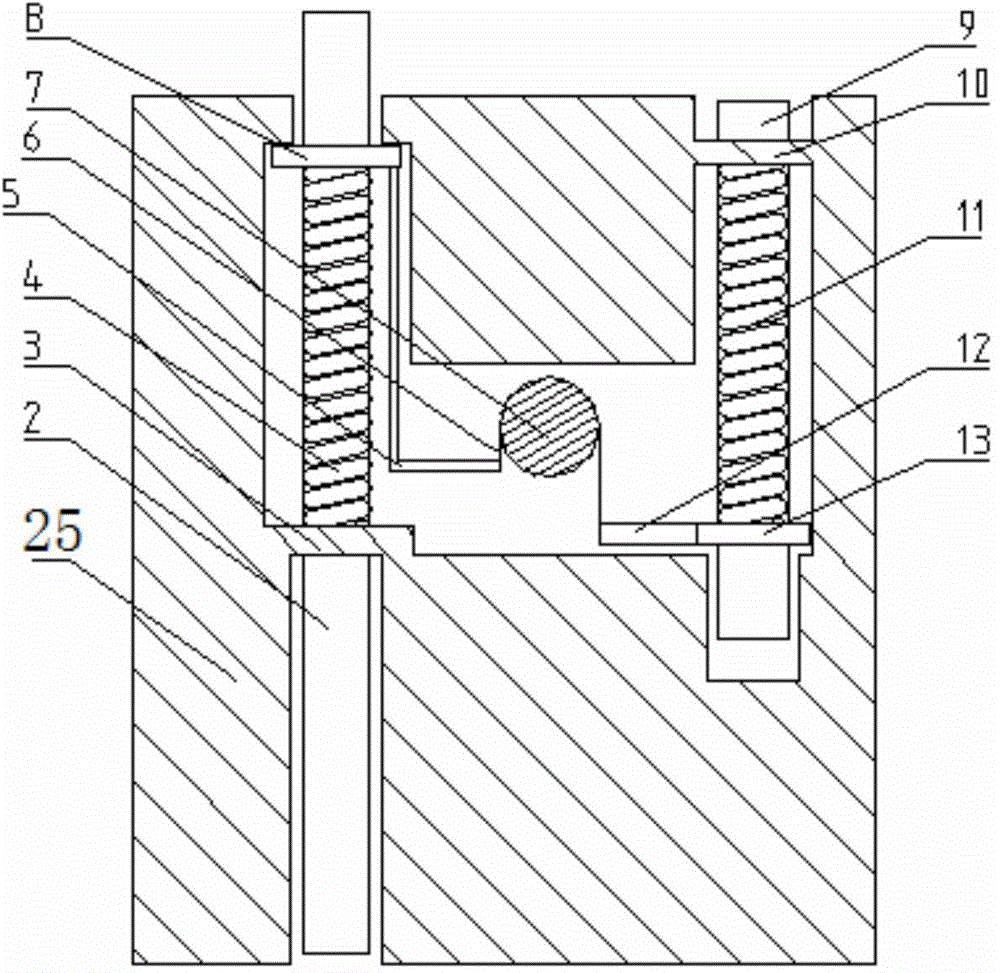

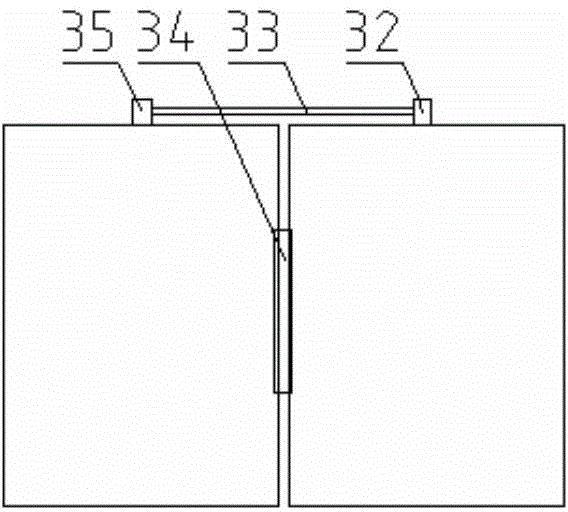

[0016] Such as figure 1 As shown, the chain 21 is installed on the door frame, and all the narrow doors are connected by hinges 34. The side of the last narrow door 25 is provided with a wide door 29 connected to the door frame through a rotating shaft 30, and the wide door 29 is next to the end. Narrow door 25, first fixed shaft 22 is fixed on the right side upper end surface of first narrow door 24, and second fixed shaft 28 is fixed on the left side upper end surface of last narrow door 25, first fixed shaft 22 and second fixed shaft 28 Connect with the first pull bar 23 and the second pull bar 27 respectively, the other end of the first pull bar 23 and the second pull bar 27 are fixed on the chain 21; All narrow doors slide along the corner track 36, the chain 21 is located at the top of the corner track 36, Its walking direction is the same as the corner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com