Valve element structure with high pressure difference and low flow

A technology of flow valve and high pressure difference, which is applied in the direction of lifting valve, valve device, engine components, etc., to achieve the effect of increasing life, easy high-precision adjustment, and enhancing the ability to reduce pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

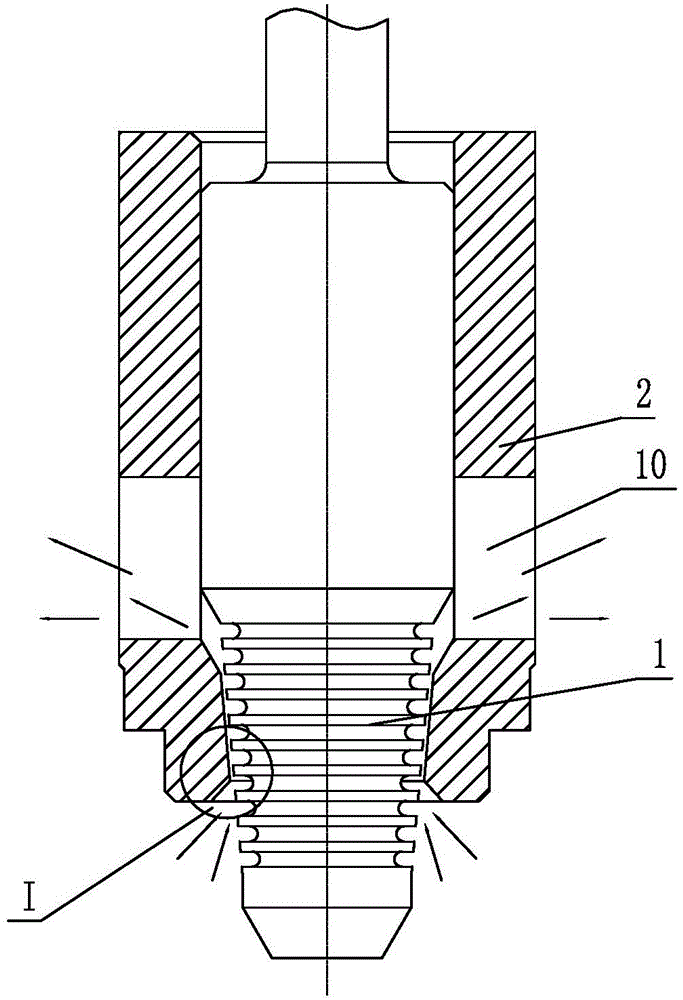

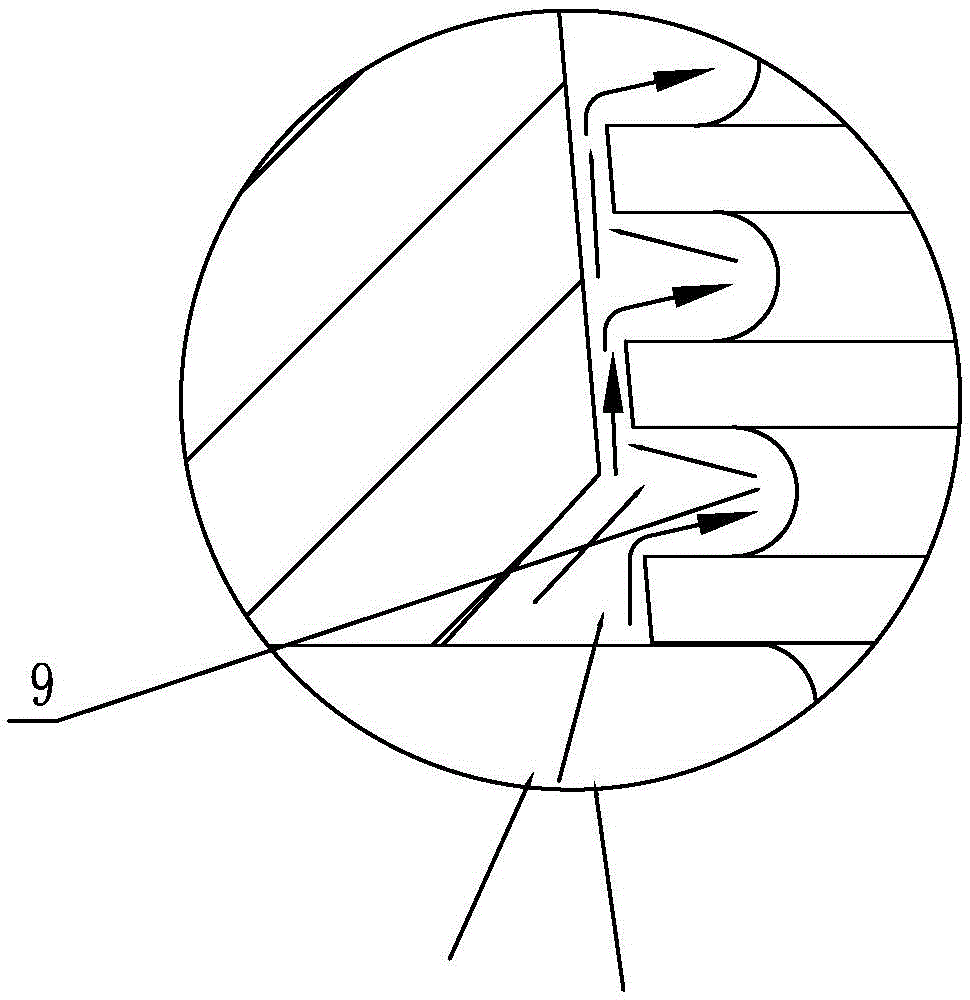

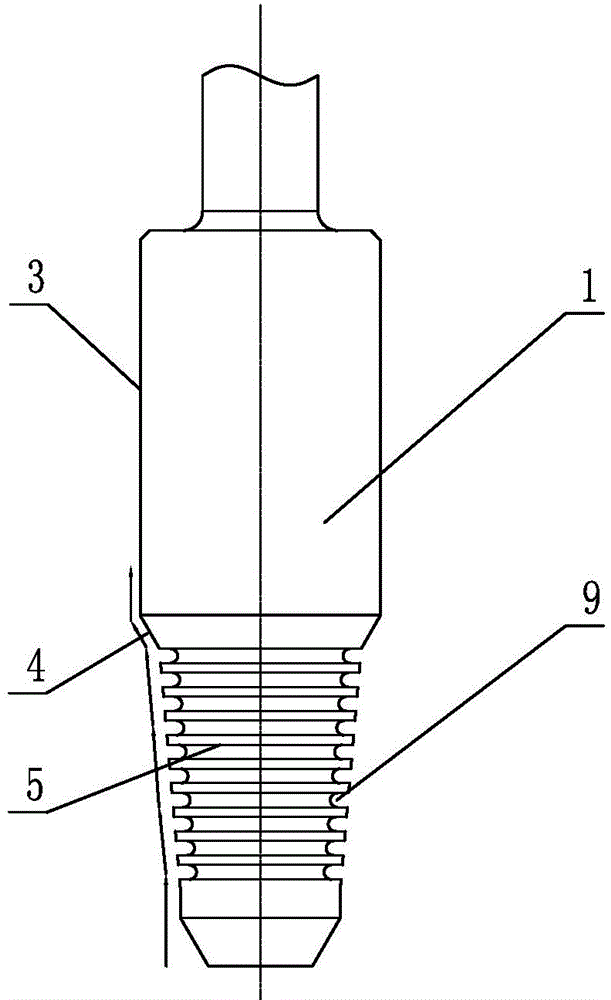

[0016] Such as Figure 1 ~ Figure 4 As shown: the valve core structure with high pressure difference and small flow includes valve core 1, valve seat 2, valve core guide surface 3, valve core sealing surface 4, valve core cone surface 5, valve seat guide surface 6, valve seat sealing surface 7 , Valve seat cone 8, groove 9, adjustment window 10, etc.

[0017] Such as figure 1 As shown, the present invention includes a valve seat 2 and a valve core 1 arranged in the inner cavity of the valve seat 2. The valve core 1 is sequentially divided into a valve core guide surface 3, a valve core sealing surface 4 and a valve core cone surface 5 from top to bottom. Three sections, a plurality of grooves 9 parallel to each other are opened on the conical surface 5 of the valve core, and the depth of each groove 9 is equal; 1. Valve seat sealing surface 7 and valve seat cone surface 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com