A plastic pipe drainage system with spiral single blade

A plastic pipe and drainage system technology, which is applied in the field of building drainage pipes, can solve problems such as increased noise, odor return from floor drains, and pressure fluctuations, and achieve the effects of preventing odor return, reducing drainage noise, and avoiding alternating impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, achieved objects and effects of the present invention easy to understand and understand, the present invention is further described below.

[0036] see Figure 5 and Image 6 Shown is a plastic pipe drainage system with a spiral single-blade, including a tee joint 300 and an upper joint 310, a lower joint 320, and an upper riser 100a and a lower riser 100b respectively connected to the tee joint 300 and the horizontal joint 330. , Horizontal tube 200.

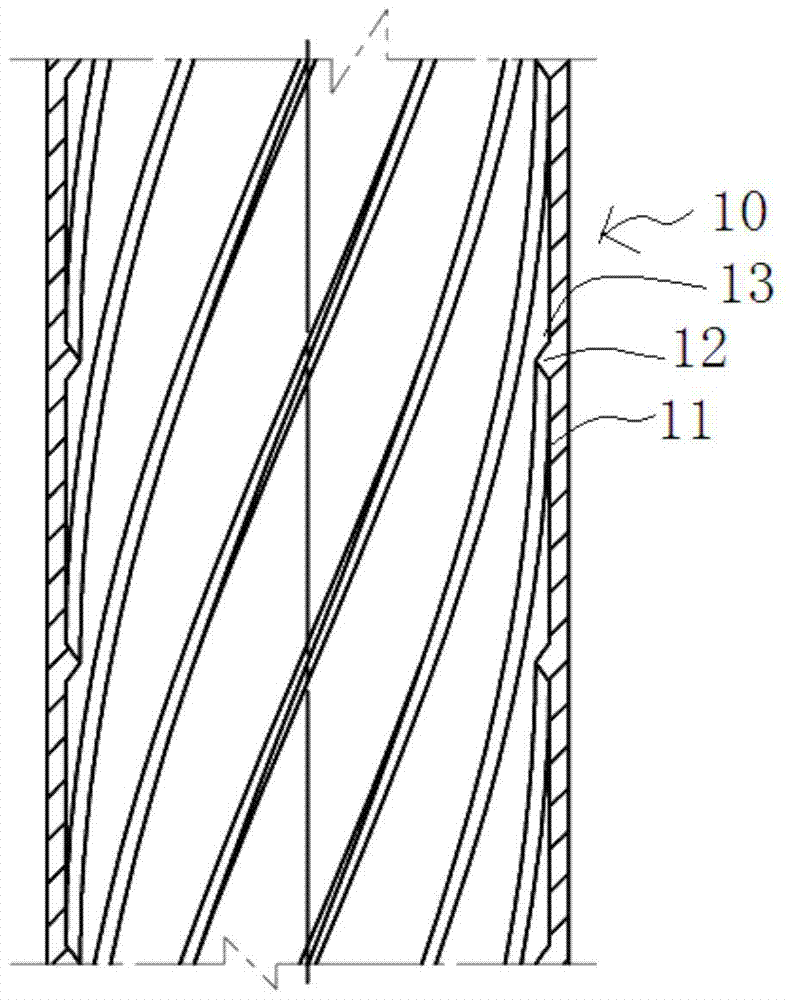

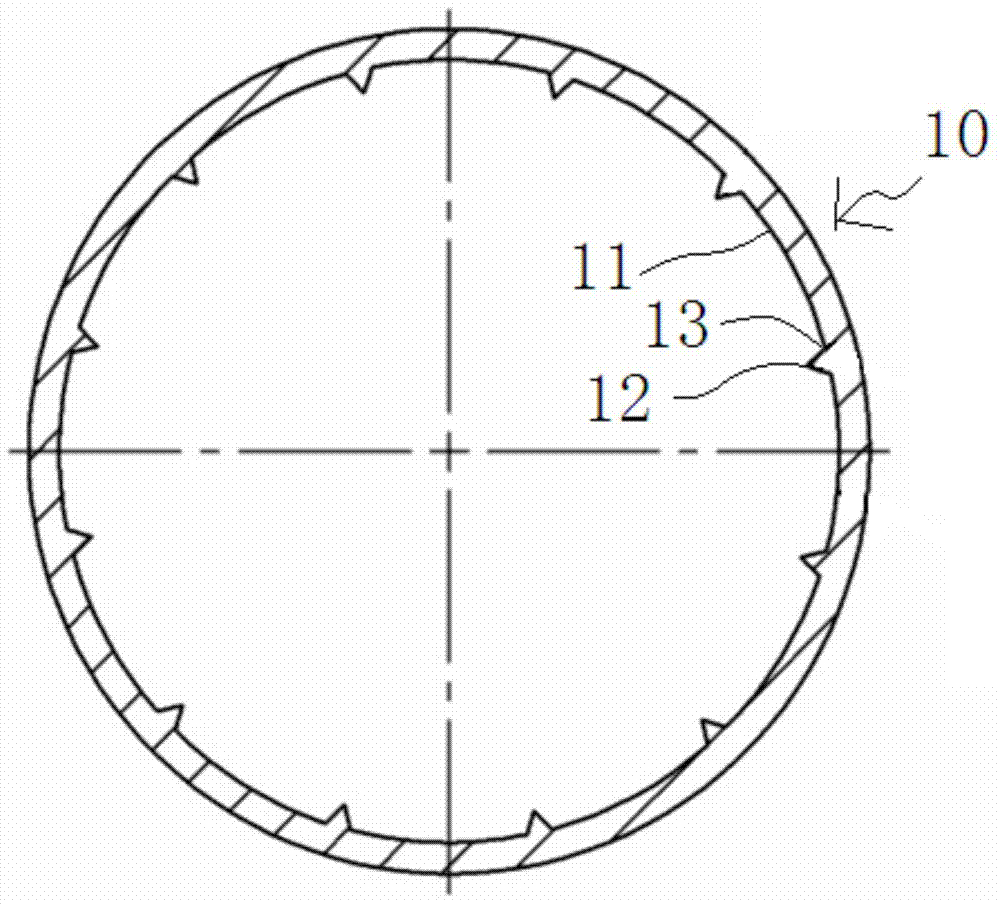

[0037] combine Figure 7 to Figure 9As shown, the structures of the upper riser 100a and the lower riser 100b are the same, and the upper riser 100a is described here as an example. A single helical blade 120a is coaxially disposed on the inner wall 110a of the upper riser 100a along the axis of the riser. The connection between the root 121a of the helical single blade 120a and the inner wall 110 of the upper riser is an arc transition structure 130a, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com