Inner reflection lamp

一种内反射、灯具的技术,应用在照明领域,能够解决缩减灯源使用寿命、产生高热等问题,达到灯具体积容易、效率高、出光角度容易控制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The internal reflection lamp of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

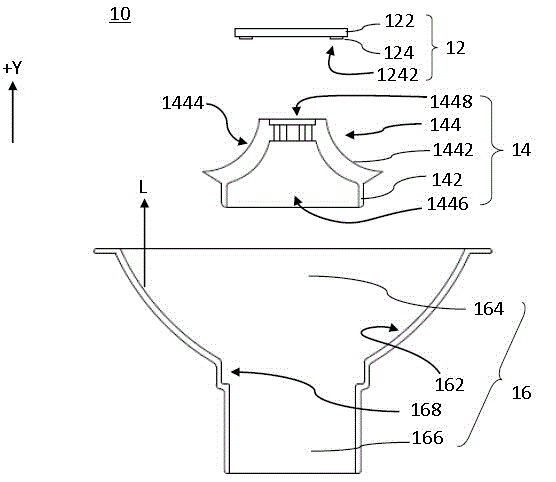

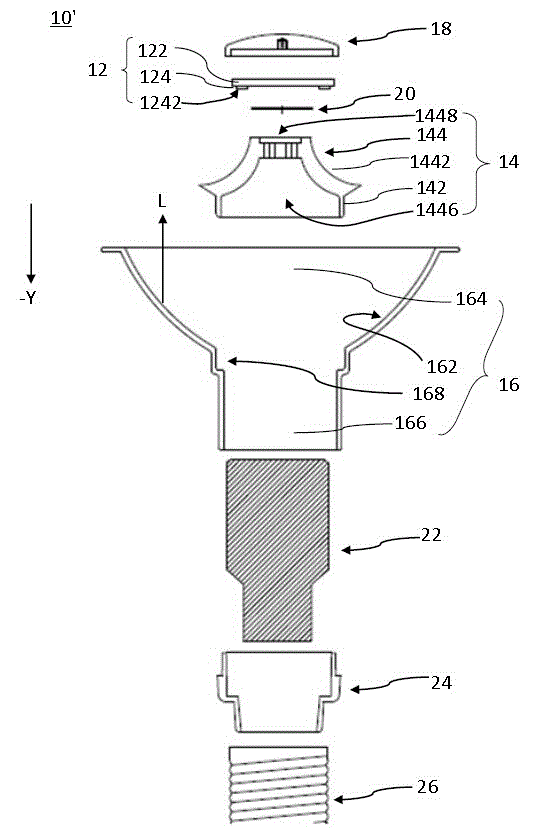

[0032] Please refer to figure 1 , is an exploded schematic view of the internal reflection lamp according to Embodiment 1 of the present invention, wherein all components are cut along the optical axis. Such as figure 1 As shown, the internal reflection lamp 10 includes a light emitting unit 12 , a reflector 14 and a cup 16 . exist figure 1 In the description, the internal reflection lamp 10 is described by taking PAR30 as an example.

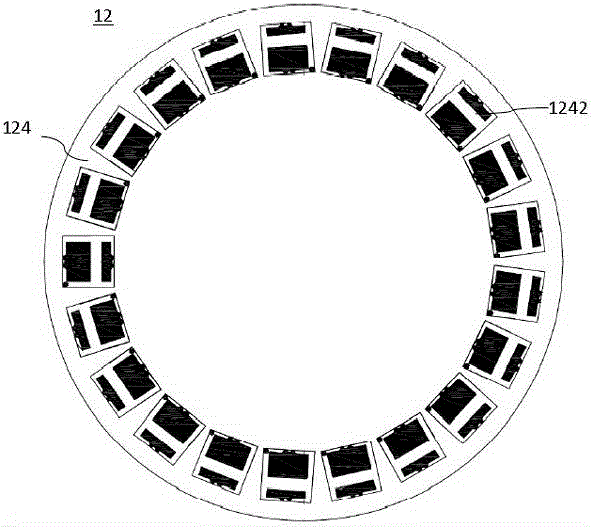

[0033] The light emitting unit 12 includes a circular plate-shaped light bottom 122 and a light emitting portion 124 fixed on the light bottom 122 . Specifically, the light-emitting part 124 is fixed on the side of the lamp bottom 122 facing the reflector 14, so that the light emitted by the light-emitting part 124 will not be directly emitted to the outside of the lamp,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com