Thick film chip resistor structure

A chip resistor, thick film technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of increasing processing difficulty, increasing production costs, and low economic benefits, improving heat dissipation effect and overall power, and increasing overall heat dissipation. The effect of volume and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

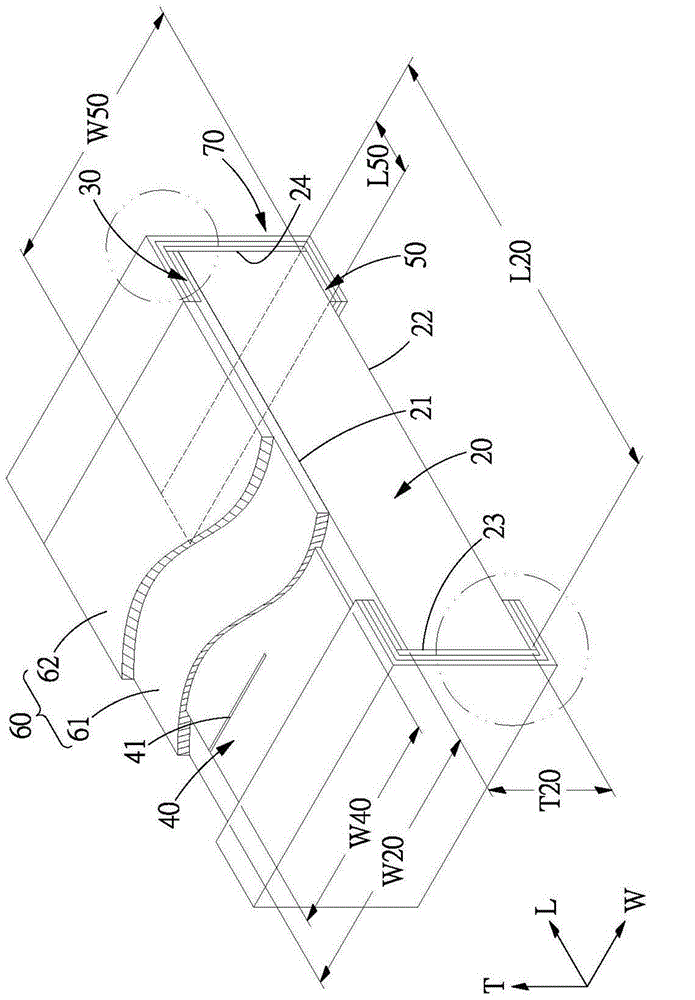

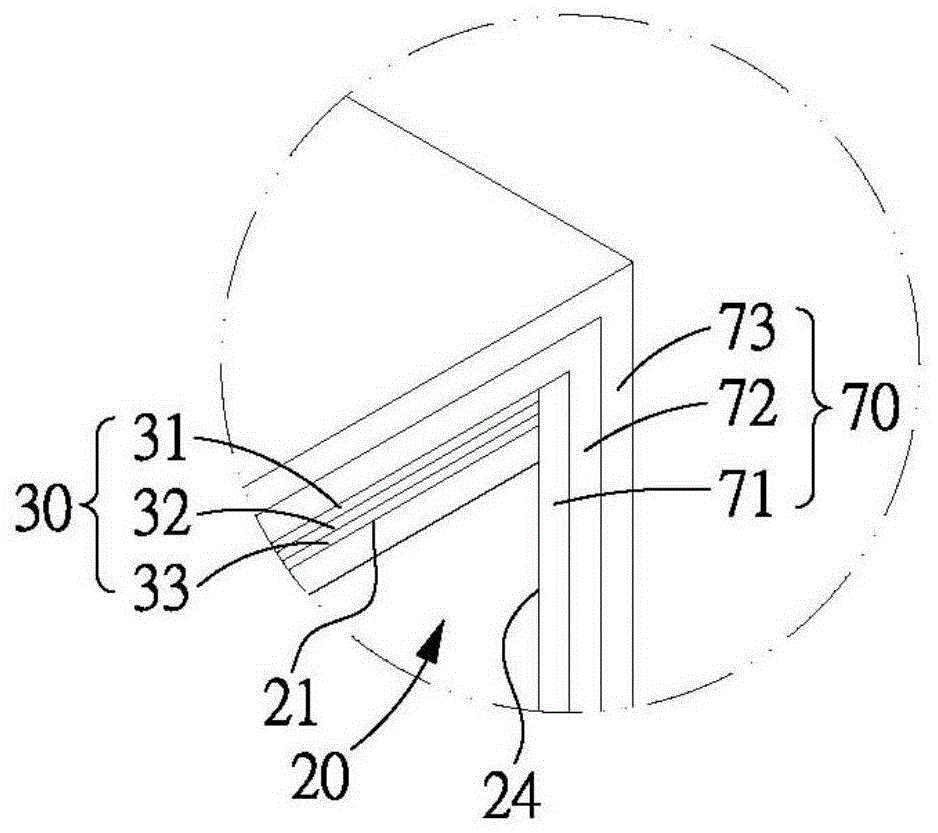

[0037] A preferred embodiment of the thick film chip resistor structure of the present invention is shown in Figures 2 to 3,

[0038] The thick film chip resistor structure of the present invention comprises:

[0039] A substrate 20 is made of high-purity alumina porcelain, and the substrate 20 is a square block structure formed along the length direction L, width direction W, and thickness direction T, wherein the length direction L, width direction W and the The thickness direction T is a three-dimensional direction perpendicular to each other, the substrate 20 has a length dimension L20 in the length direction L, the substrate 20 has a width dimension W20 in the width direction W, and the substrate 20 has a thickness dimension in the thickness direction T T20, the length dimension L20 is 6.35 millimeters, the width dimension W20 is 3.20 millimeters, and the thickness dimension T20 is 1 millimeter; and the two ends of the substrate 20 in the thickness direction T are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com