Air conditioning system

An air-conditioning system and gas collecting pipe technology, which is applied in the direction of compressors, refrigeration components, refrigerators, etc., can solve the problems affecting the performance of the unit, the refrigerant gas cannot pass through the heat exchange tubes, and the accumulation of refrigerated oil, so as to achieve uniform gas distribution and improve reliability. performance, to ensure the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

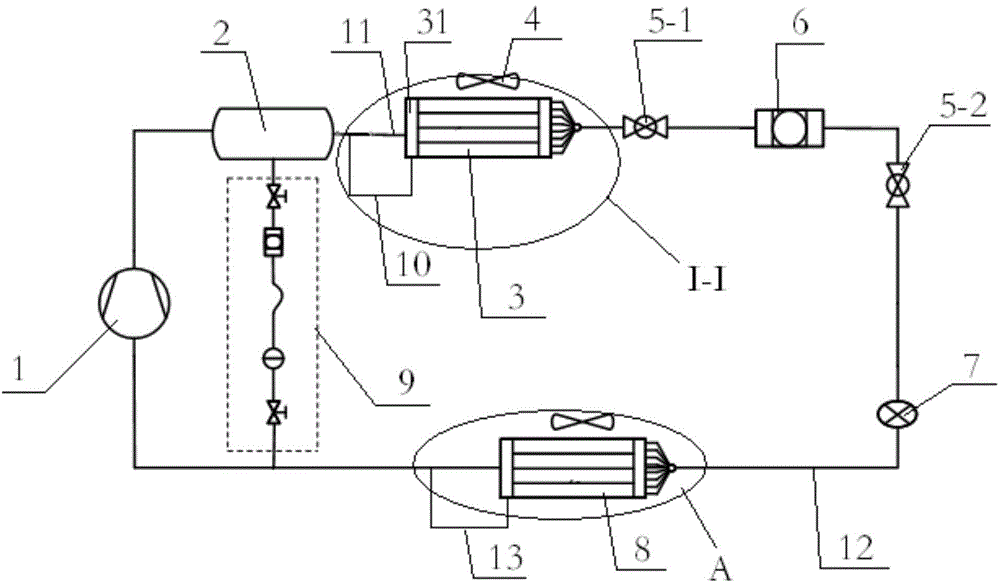

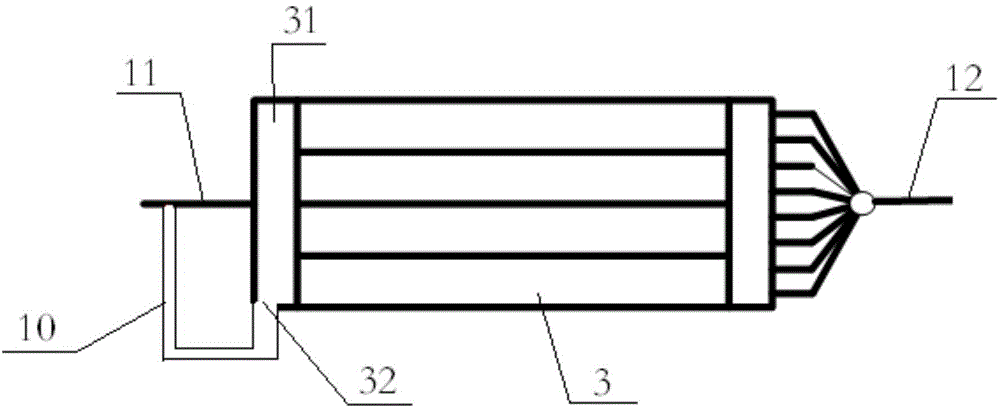

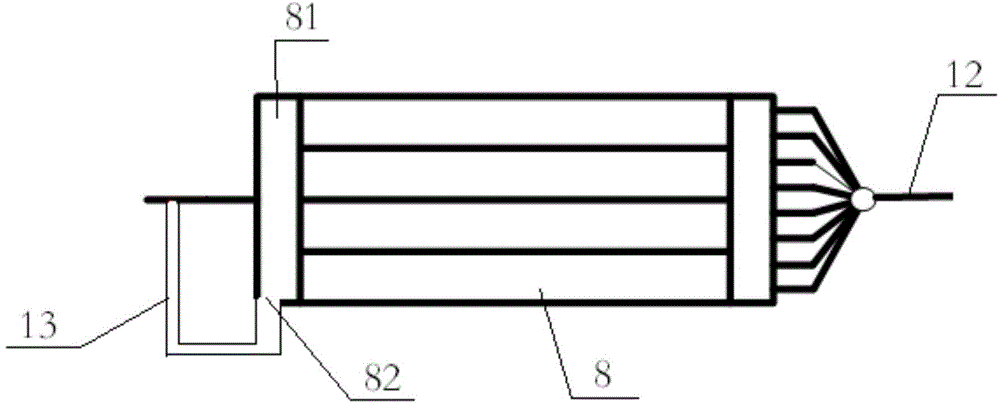

[0038] Such as Figure 1 to Figure 3 As shown, the air conditioning system provided by the present application includes a compressor 1 , an oil separator 2 , a first heat exchanger 3 , a second heat exchanger 8 and a third oil return pipeline 9 . The first heat exchanger 3 is arranged in the indoor unit of the air conditioning unit. The exhaust port of the compressor 1 is connected to the inlet of the oil separator 2 , and the oil outlet of the oil separator 2 is connected to the suction port of the compressor 1 through the third oil return pipeline 9 . One end of the second heat exchanger 8 is connected to the outlet end of the first heat exchanger 3 , and the other end is connected to the suction port of the compressor 1 . Wherein, the inlet end of the first heat exchanger 3 is provided with a first air collecting pipe 31, and several heat exchange pipes are arranged in the first heat exchanger 3, and the first air collecting pipe 31 is connected with the first air collecti...

Embodiment 2

[0057] Such as Figure 4 As shown, the difference between the air-conditioning system provided in this embodiment and the air-conditioning system provided in Embodiment 1 is that the other end of the first oil return pipeline 10 communicates with the third oil return pipeline 9 . In this solution, since the refrigerated oil retained in the first heat exchanger 3 does not need to pass through the oil separator 2, it returns directly to the third oil return line 9, and then returns to the compressor 1, reducing the amount of residual oil returning to the oil separator again. 2, so this solution has better beneficial effects than the solution provided by Example 1.

[0058] Apart from this, this embodiment is the same as the specific embodiment, and will not be repeated here.

Embodiment 3

[0060] Such as Figure 5 As shown, the difference between the air-conditioning system provided in this embodiment and the air-conditioning system provided in Embodiment 1 is that the other end of the first oil return pipeline 10 communicates with the suction port of the compressor 1 . In this scheme, since the refrigerated oil retained in the first heat exchanger 3 does not need to pass through the oil separator 2 and directly returns to the compressor 1, the trouble caused by the residual oil returning to the oil separator 2 is reduced, so This solution has better beneficial effects than the solution provided by Example 1.

[0061] Apart from this, this embodiment is the same as the specific embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com