A system and method for measuring the impact force of electric spark discharge

A measurement system and impact force technology, applied in the direction of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of limited force sensor natural frequency, difficult implementation, and difficulty in correctly measuring discharge impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

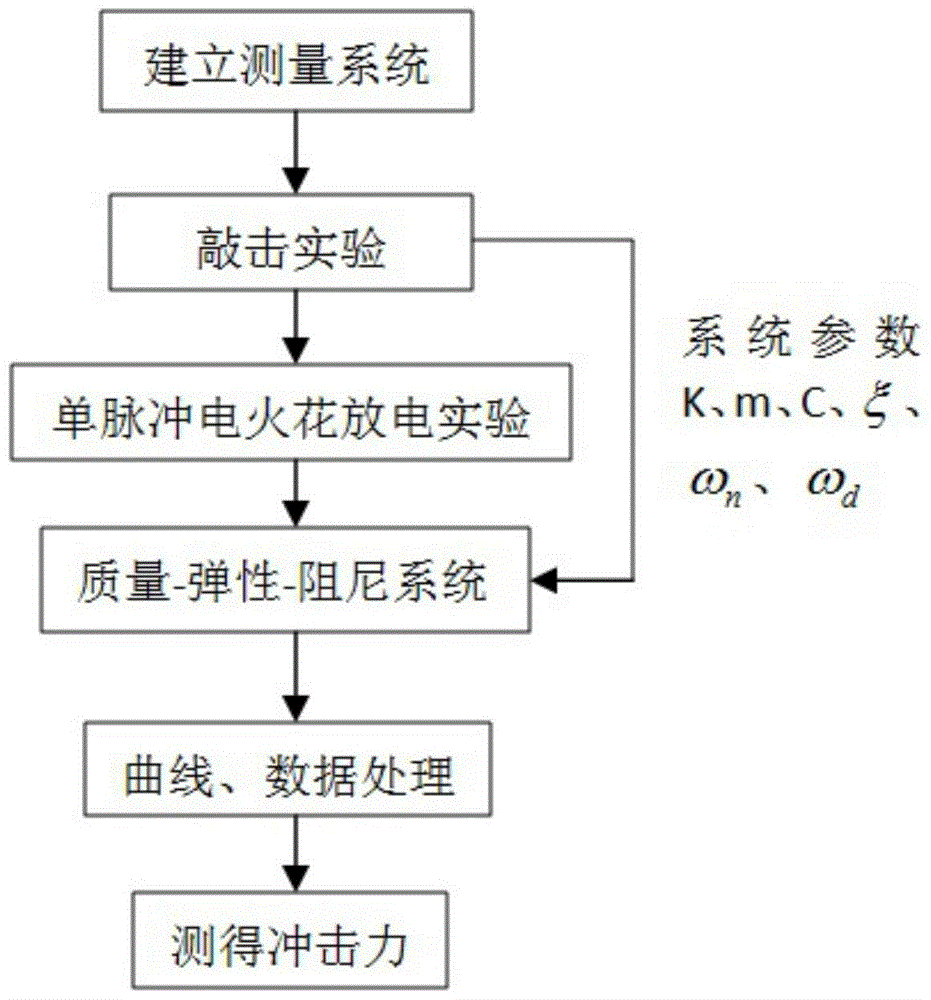

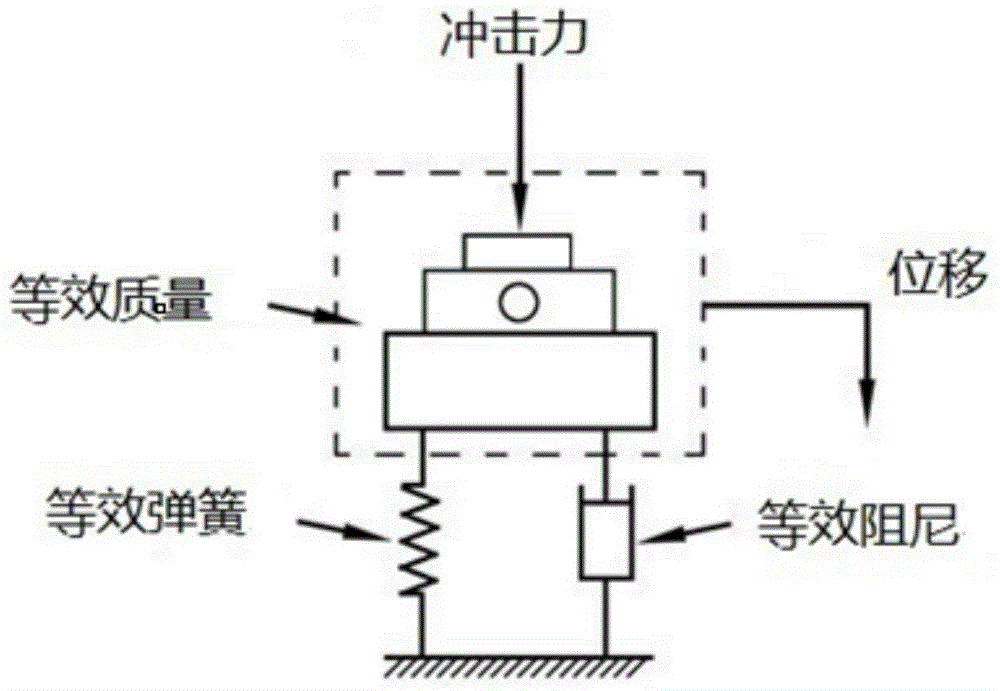

Method used

Image

Examples

Embodiment Construction

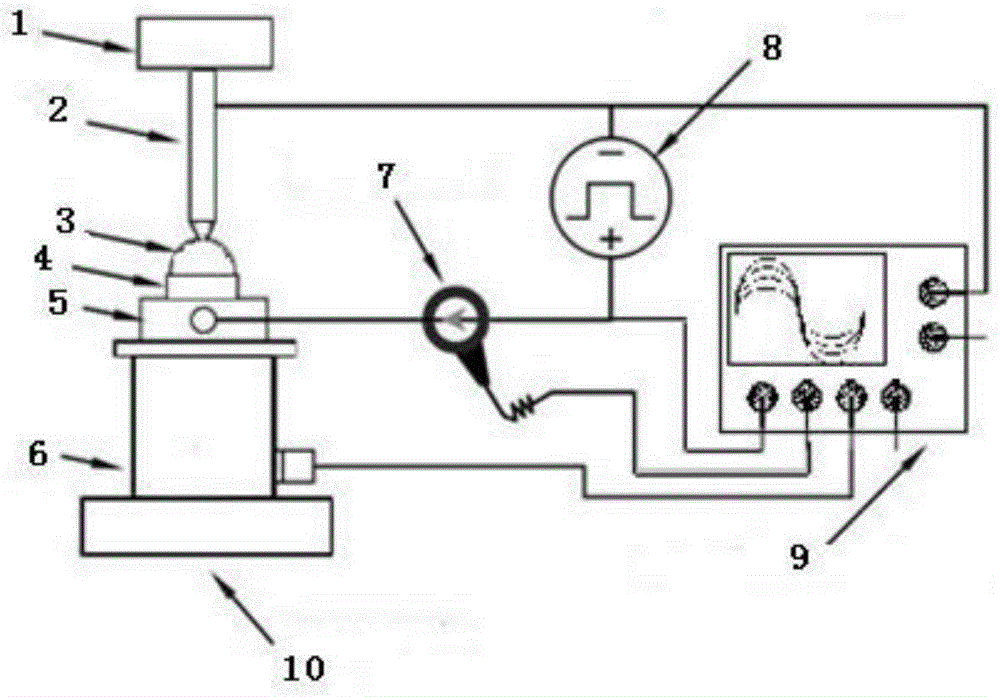

[0010] A measuring system for electric spark discharge impact force, including a single pulse power supply, a working part and a measuring part,

[0011] The working part includes: a needle electrode fixture, a needle electrode, a workpiece electrode, and a workpiece electrode fixture. The needle electrode fixture is connected to the needle electrode, the workpiece electrode fixture is connected to the workpiece electrode, and the single pulse power supply is connected to the workpiece electrode. The needle electrode and the workpiece electrode are connected to form a loop, and the single pulse power supply provides a single pulse discharge;

[0012] The measurement part includes an oscilloscope, a force sensor, and a current probe. The force sensor is connected to the workpiece electrode fixture. The current probe is in the loop of the single pulse power supply, the needle electrode, and the workpiece electrode. The current probe captures the single pulse discharge The oscill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com