Device and method for controlling residual aluminum concentration in high pH raw water treatment process

A treatment process, residual aluminum technology, applied in water treatment parameter control, special compound water treatment, neutralization water/sewage treatment, etc., can solve the problem of high residual aluminum concentration in factory water, strict preparation reaction conditions, production There are many raw material components, etc., to achieve the effect of stable and reliable adjustment effect, simple selection, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

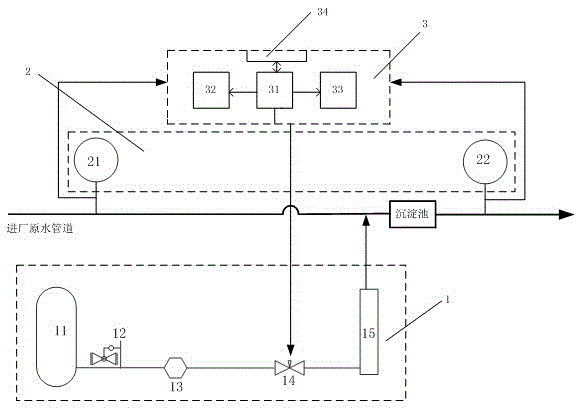

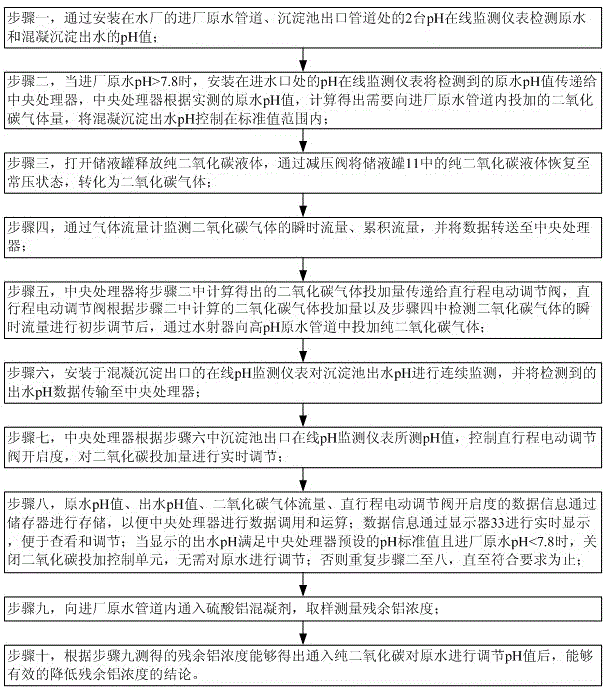

Image

Examples

Embodiment 1

[0072] First, the raw water of a reservoir in the south was selected as the raw water for the experiment. The turbidity of the raw water entering the plant was 2.32 NTU, the water temperature was 21.2 °C, the total aluminum was 0.23 mg / L, and the pH = 8.974. The coagulant was aluminum sulfate, of which Al 2 o 3 The content is 7.8%;

[0073] Then, according to the drinking water standard inspection method metal index GB5750.6-2006, the aluminum concentration in the water was determined by inductively coupled plasma mass spectrometry;

[0074] Then, measure equal volumes of raw water into two beakers respectively, and mark them as standard sample 1 and standard sample 2;

[0075] Then, pass pure carbon dioxide gas into the standard sample 1, and control the dosage of carbon dioxide through the flowmeters at the inlet and outlet until the pH value of the raw water is adjusted from 8.974 to 7.524. At this time, the dosage of carbon dioxide is 79mg / L .

[0076] Then, take 1000ml...

Embodiment 2

[0079]First, the raw water of a reservoir in the south was selected as the raw water for the experiment. The turbidity of the raw water entering the plant was 2.60 NTU, the water temperature was 16.3 °C, the total aluminum was 0.11 mg / L, and the pH = 8.271. The coagulant was aluminum sulfate, of which Al 2 o 3 The content is 7.8%;

[0080] Then, according to the drinking water standard inspection method metal index GB5750.6-2006, the aluminum concentration in the water was determined by inductively coupled plasma mass spectrometry;

[0081] Then, measure equal volumes of raw water into two beakers respectively, and mark them as standard sample 1 and standard sample 2;

[0082] Then, pass pure carbon dioxide gas into the standard sample 1, and control the dosage of carbon dioxide through the flowmeters at the inlet and outlet until the pH value of the raw water is adjusted from 8.271 to 7.320. At this time, the dosage of carbon dioxide is 79mg / L .

[0083] Then, take 1000ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com