Method and system for detecting evaluation information of food flavor quality

A quality evaluation and information detection technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unstable flavor quality, non-standardized aroma quality evaluation standards, poor product aroma fitting effect, etc., to achieve reliable experiments The effect of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

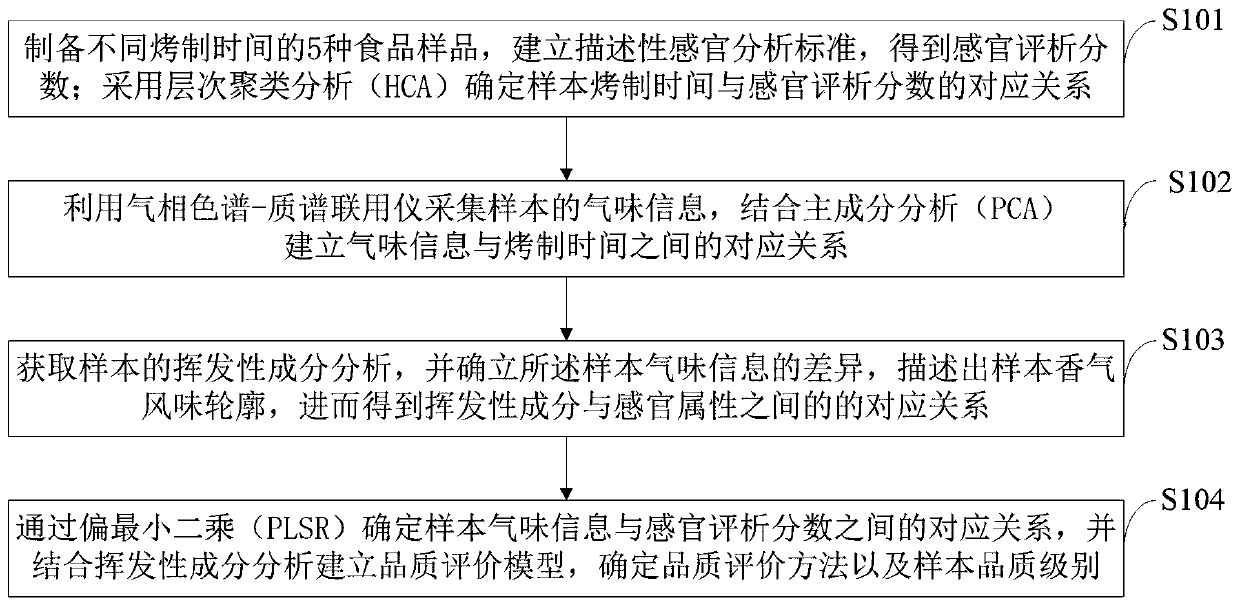

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the quality evaluation method is applied in the evaluation of garlic powder:

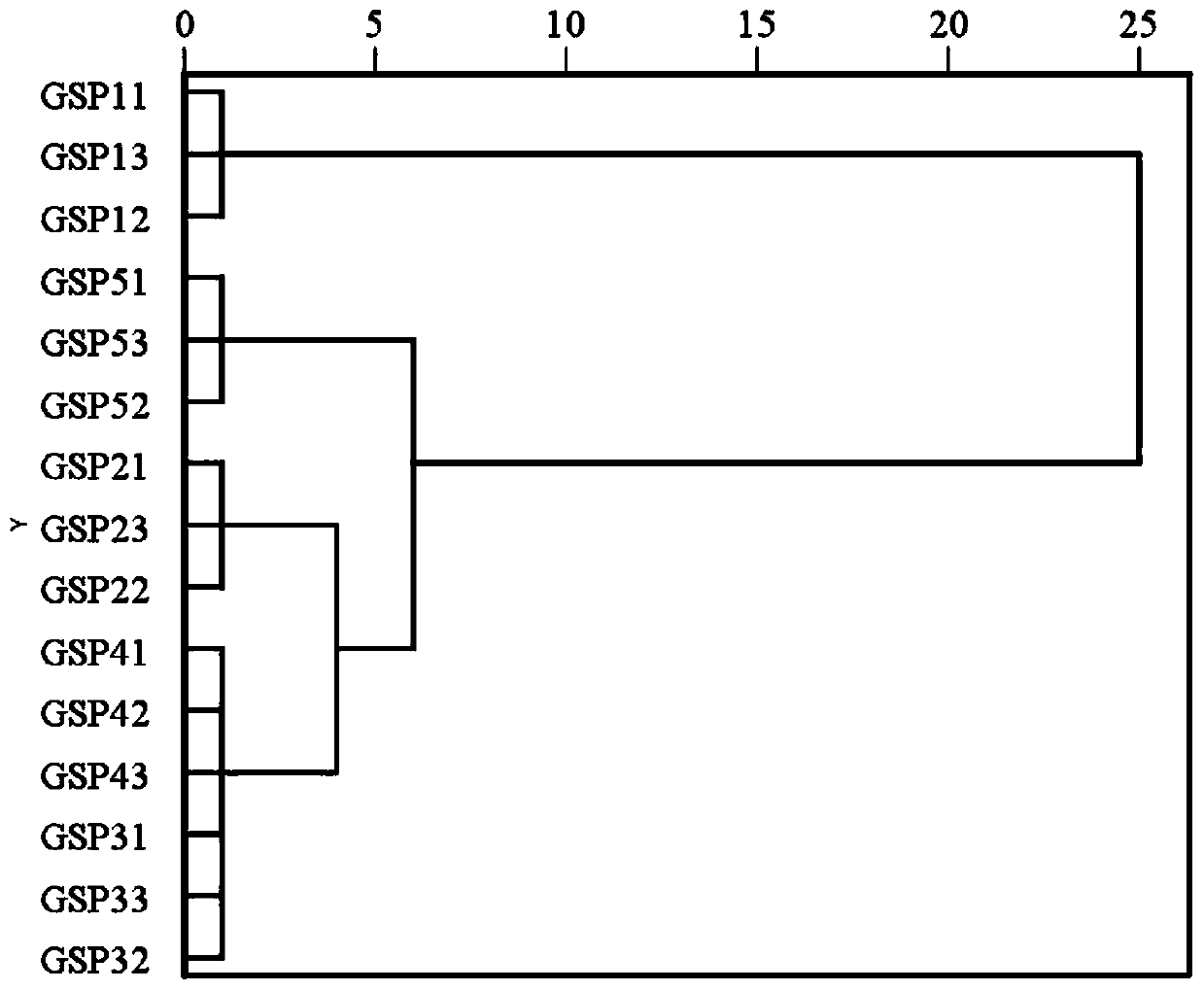

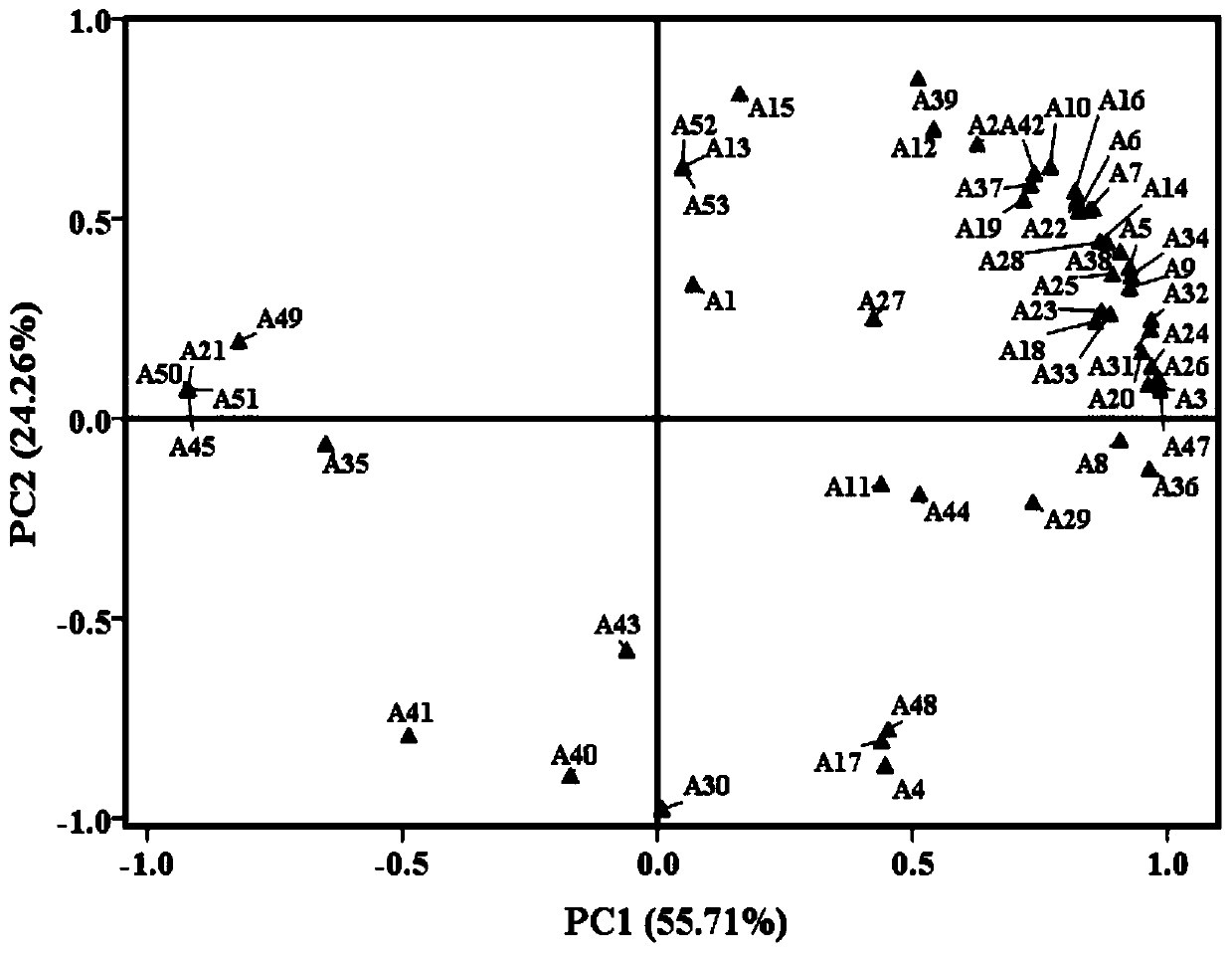

[0082] Raw garlic of uniform size and quality was selected from the cold storage, peeled and sliced, and then the slices were evenly distributed in stainless steel trays, and dried at 60°C for 5h, 6h, 7h and 8h. Garlic slices can be obtained by drying at a constant temperature of 60°C in a constant temperature blast drying oven. The corresponding relationship between sample baking time and sensory evaluation scores is as follows: figure 2 shown.

[0083] The moisture content is determined by the National Food Safety Standard Determination of Moisture in Food (GB5009.3-2016). Choose the direct drying method for determination. Garlic slices were dried at 60°C. Measure the mass every 15 minutes in the initial stage of drying, measure it every 30 minutes from 120 to 300 minutes, and measure it every 60 minutes after 300 minutes to ensure that the water content of the sample mee...

Embodiment 2

[0102] Embodiment 2: the evaluation method is applied in the evaluation of kiwi fruit juice:

[0103] Choose kiwifruit of the same variety and the same origin to keep them intact and undamaged. Specifically, it is advisable to choose eight-ripe kiwi fruit, which contains many nutrients and has a good flavor.

[0104] The selected kiwis are cleaned, peeled, beaten, filtered and homogenized. Specifically, to remove drunk, deteriorated and hard fruits, first wash them with clean water, remove silt and dirt, disinfect them with potassium permanganate solution, rinse them with clean water, and drain them for later use. Put the fruit into the crusher and crush it, put it into the juicer to extract the juice. Add sterilized water to the pulp after the first squeezed juice, stir well and then squeeze it again to increase the juice yield. In order to prevent the loss of nutrients in this process, certain antioxidant and ascorbic acid solution can be added to the crushed fruit pulp. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com