Sterilization test fixture for small-volume ampoule injection product

An ampoule injection and test fixture technology, which is applied in laboratory utensils, supporting utensils, chemical instruments and methods, etc., can solve the problems of small volume and weight, affecting the test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

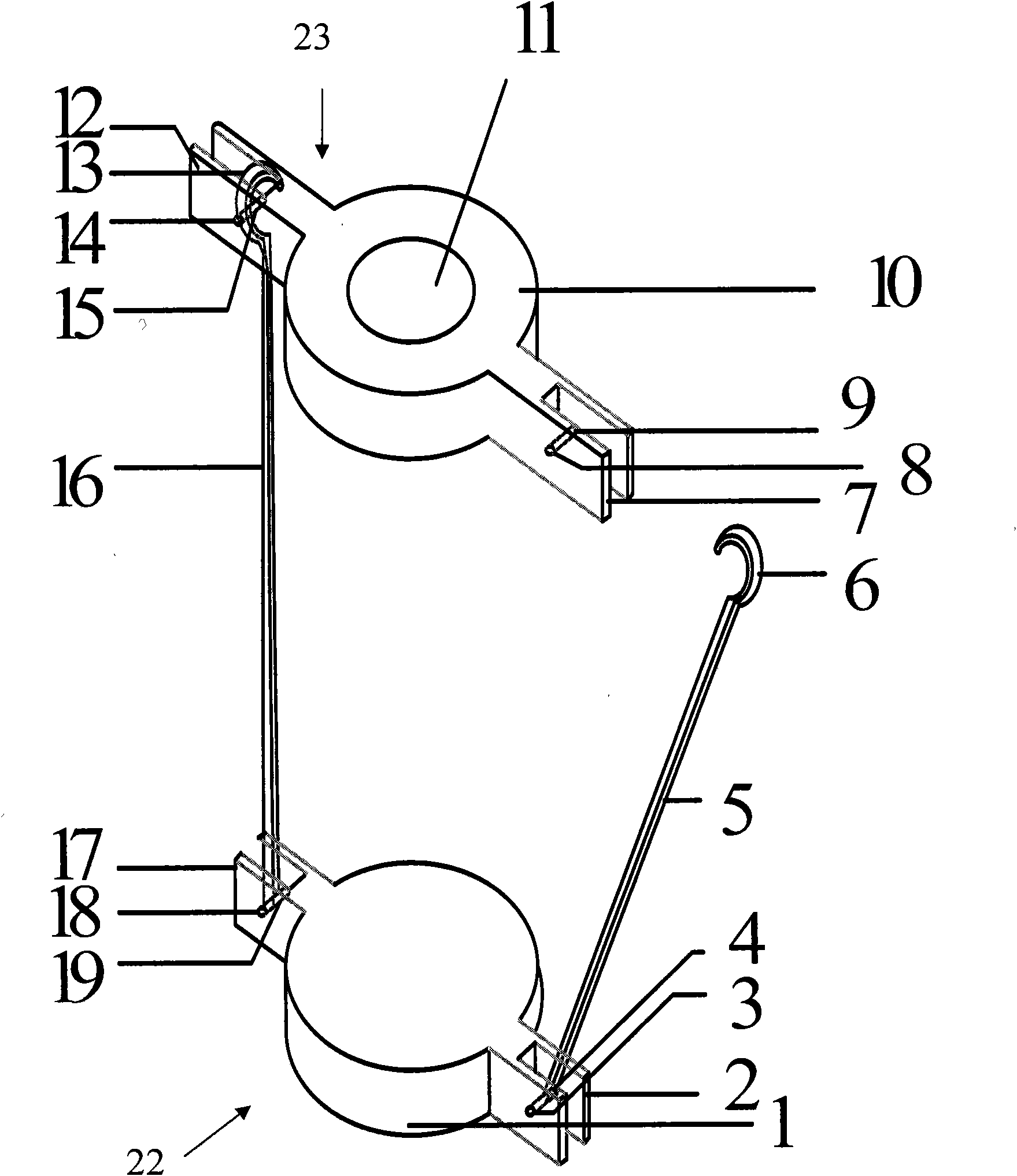

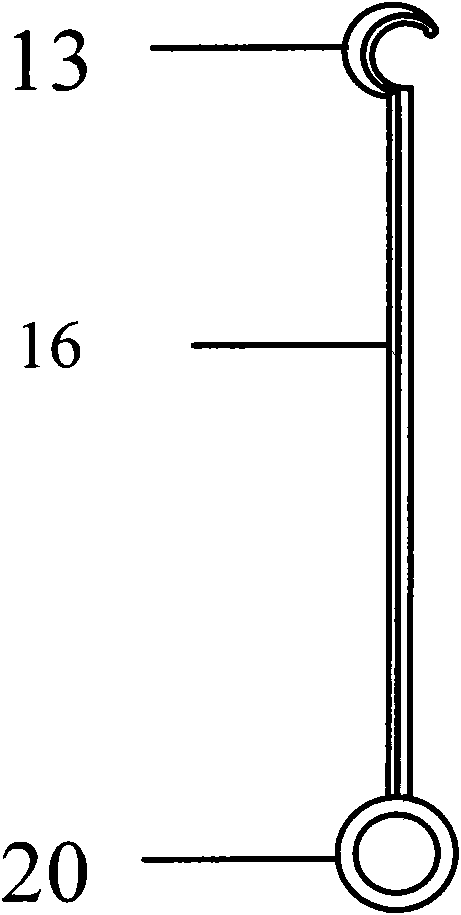

[0028] Below in conjunction with accompanying drawing, describe in detail the implementation of the small capacity ampoule injection product sterilization test fixture of the present invention, figure 2 It is a perspective view of the structure of the small-capacity ampoule injection product sterilization test fixture of the present invention. image 3 It is a structural schematic diagram of the left pull rod of the small-capacity ampoule injection product sterilization test fixture of the present invention. Figure 4 It is a structural schematic diagram of the right pull rod of the small-capacity ampoule injection product sterilization test fixture of the present invention. Figure 5 It is a bottom view of the upper fixture of the small-capacity ampoule injection product sterilization test fixture of the present invention. like Figure 2-5 As shown, the small-capacity ampoule injection product sterilization test fixture of the present invention is composed of a lower fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com