Touch screen, production method thereof and touch display device

A technology of touch screen and sensing components, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve the problems of performance degradation of the outer frame layer and affect visual effects, etc., and achieve the effect of avoiding performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

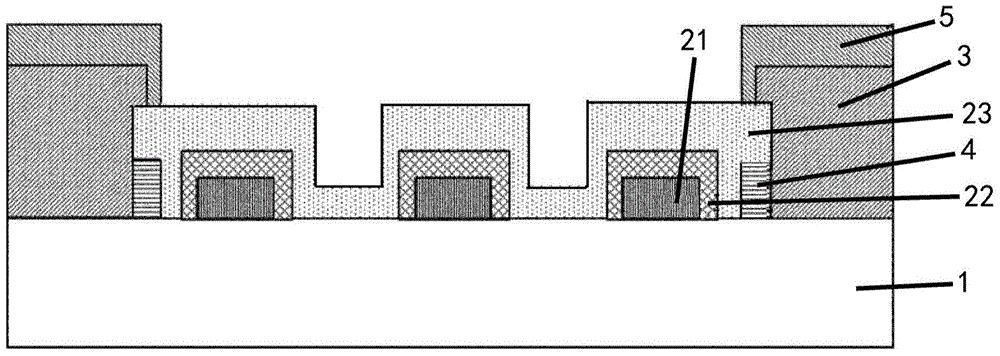

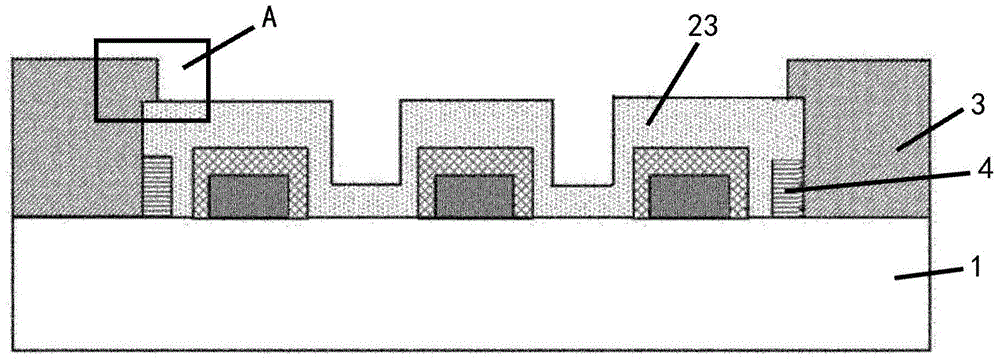

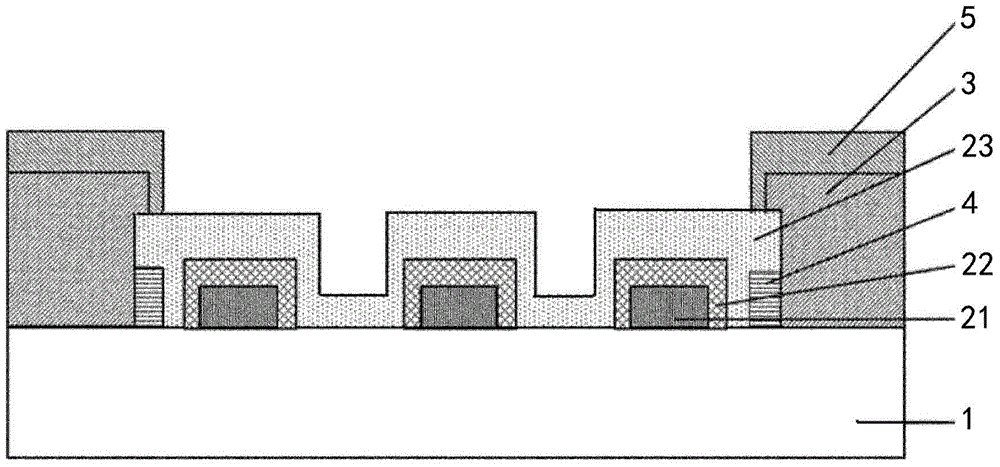

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0032] According to the general inventive concept of the present invention, a touch screen is provided, including: a substrate; a sensing component disposed on the substrate; an inner frame layer disposed to surround the sensing component; and an outer frame layer formed on the inner frame layer The peripheral outer frame layer is used to package the sensing component and the inner frame layer. When making induction components made of metal m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com