Vehicle hood panel

一种发动机、车辆的技术,应用在车辆部件、车辆安全安排、上部结构等方向,能够解决无法解决成本上升、部件个数增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

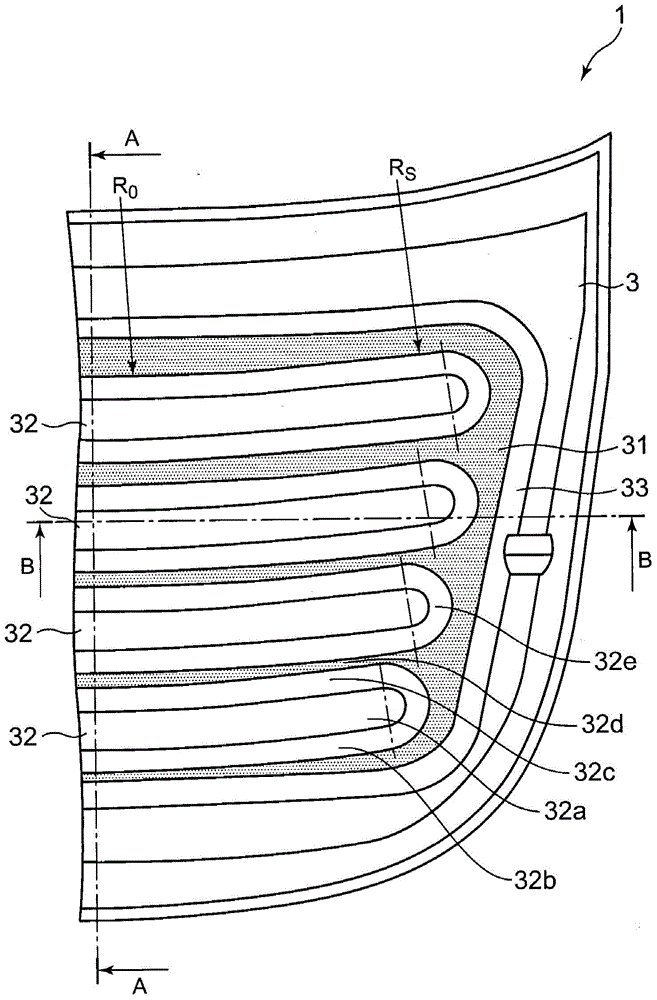

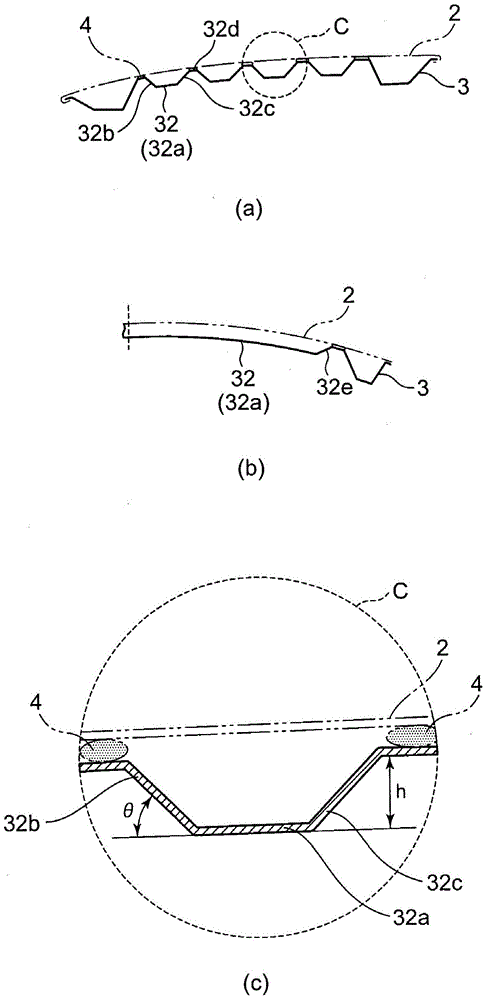

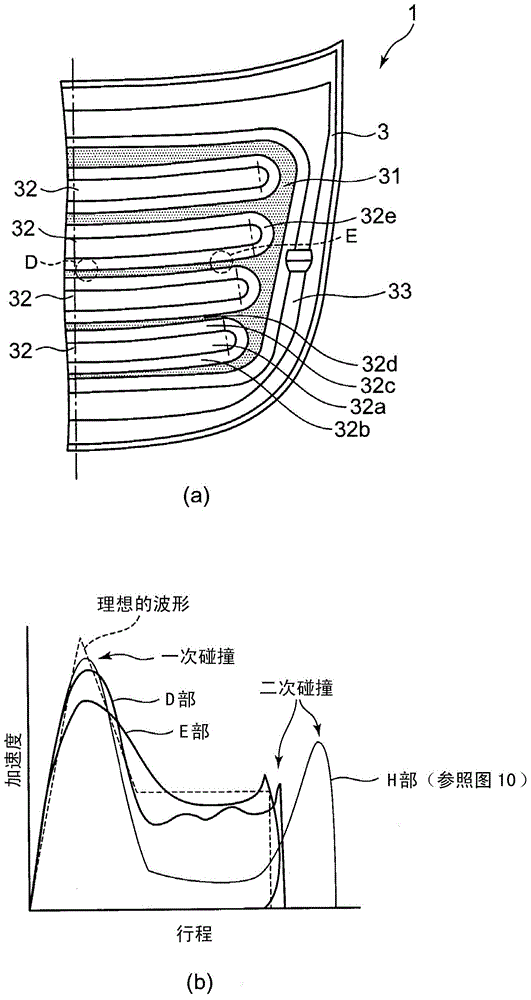

[0116] First, the structure of the vehicle bonnet according to the first embodiment of the present invention will be described. figure 1 It is a plan view showing the vehicle bonnet according to the first embodiment of the present invention, figure 2 (a) is figure 1 A-A sectional view in, figure 2 (b) is figure 1 The B-B sectional view in, figure 2 (c) is figure 2 Enlarged view of part C in (a). Such as figure 1 As shown, the vehicle engine cover 1 according to the present embodiment and Figure 28 The shown conventional vehicle hood panel 10 has the same inner panel 3 and outer panel 2 , and the outer edge of the inner panel 3 and the outer edge of the outer panel 2 are joined by hemming, for example. The inner panel 3 and the outer panel 2 are formed of metal plates such as iron, aluminum or aluminum alloy, and the thickness of the plates is, for example, 0.7 to 1.1 mm. Such as figure 1 As shown, in the center of the inner panel 3 , there is formed a magnet...

no. 2 Embodiment approach

[0129] Next, a vehicle engine cover according to a second embodiment of the present invention will be described. Figure 4 It is a plan view showing the vehicle bonnet according to the second embodiment of the present invention, Figure 5 (a) is Figure 4 A-A sectional view in, Figure 5 (b) is Figure 5 Enlarged view of part F in (a). In the rib 32 of the present embodiment, at least one of the vertical wall 32b on the vehicle front side and the vertical wall 32c on the vehicle rear side is also provided such that the ratio of the curvature radius of the upper end edge to the central portion in the left-right direction of the vehicle in a plan view The end portions in the left-right direction of the vehicle are curved such that the radius of curvature is small. In addition, if Figure 4 As shown, the rib 32 is curved so that the central portion 320 in the vehicle left-right direction protrudes forward of the vehicle in plan view. In the present embodiment, between the c...

no. 3 Embodiment approach

[0140] Next, a vehicle hood panel according to a third embodiment of the present invention will be described. Figure 7 (a) is a plan view showing a vehicle bonnet according to a third embodiment of the present invention, Figure 7 (b) is Figure 7 A-A sectional view in (a), Figure 8 (a) is Figure 7 A perspective view of part G in (b), Figure 8 (b) and Figure 8 (c) is Figure 7 Enlarged view of part G in (b). In this embodiment, at least one of the vertical walls 32b, 32c on the vehicle front side and the vehicle rear side is also provided such that the upper end edge on the side of the acrylic contact surface 31 is at the center of the vehicle left-right direction in plan view. The point that the curvature radius is smaller than the curvature radius of the end portion in the left-right direction of the vehicle is the same as that of the first and second embodiments. However, in this embodiment, with Figure 4 Unlike the case of the illustrated second embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com