Clamp assembly of amorphous alloy transformer body and amorphous alloy transformer

An amorphous alloy and transformer technology, applied in the field of transformers, can solve problems such as coils that cannot provide sufficient extrusion force, fail to meet national standards, and poor clamping effect, and achieve large clamping force, small reactance change range, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

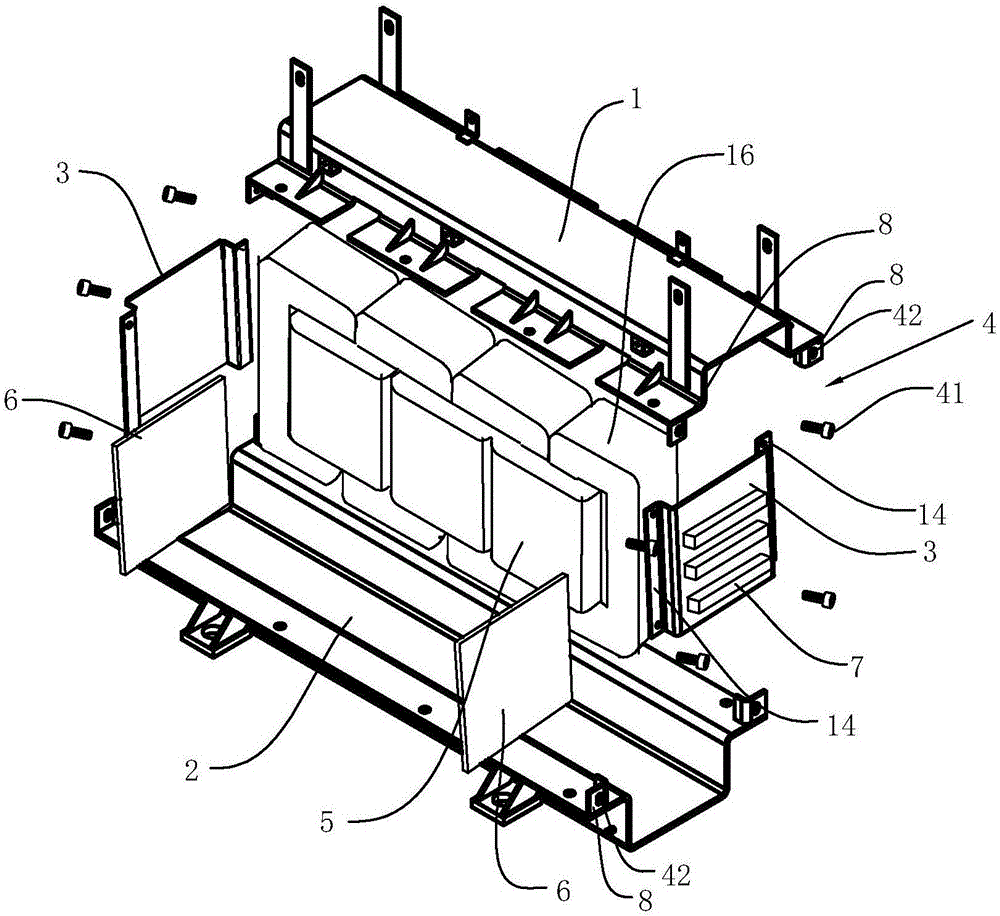

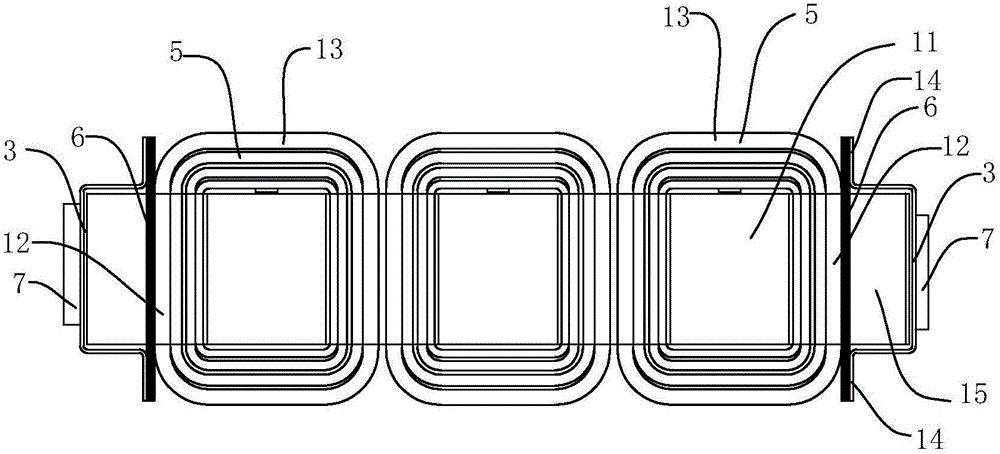

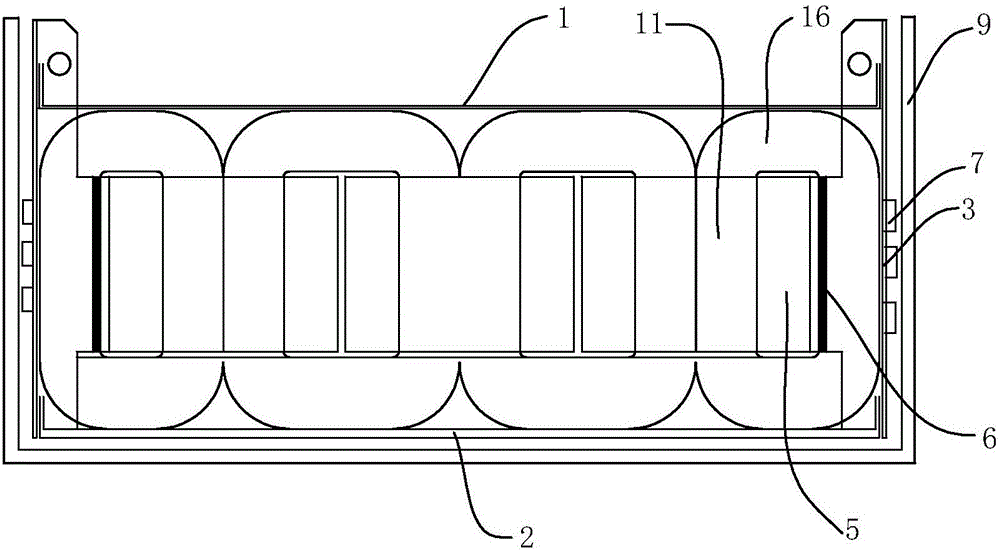

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1-Figure 3 As shown, the clamp assembly of the amorphous alloy transformer body includes an upper fixing frame 1 and a lower fixing frame 2 for fixing the transformer body 11, and a tightening assembly is arranged between the upper fixing frame 1 and the lower fixing frame 2, The tightening assembly includes two independent side clamping plates 3 and a displacement adjustment component 4 for moving and fixing the side clamping plates 3 to the inside. The side clamping plates 3 are provided with a support portion 14, and the inner side of the side clamping plates 3 is provided with a socket for inserting a transformer. The insulation reinforcing plate 6 between the iron core 16 of the body 11 and the coil 5; when the side splint 3 moves inward as a whole under the action of the displacement adjustment assembly 5, the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com