A kind of bone and meat separator

A technology of bone and meat separation and separation cylinder, which is applied in the field of bone and meat separators, can solve the problems of high cost, inconvenient manual collection, inconvenient replacement, etc., and achieve the effect of increasing service life and high bone and meat separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

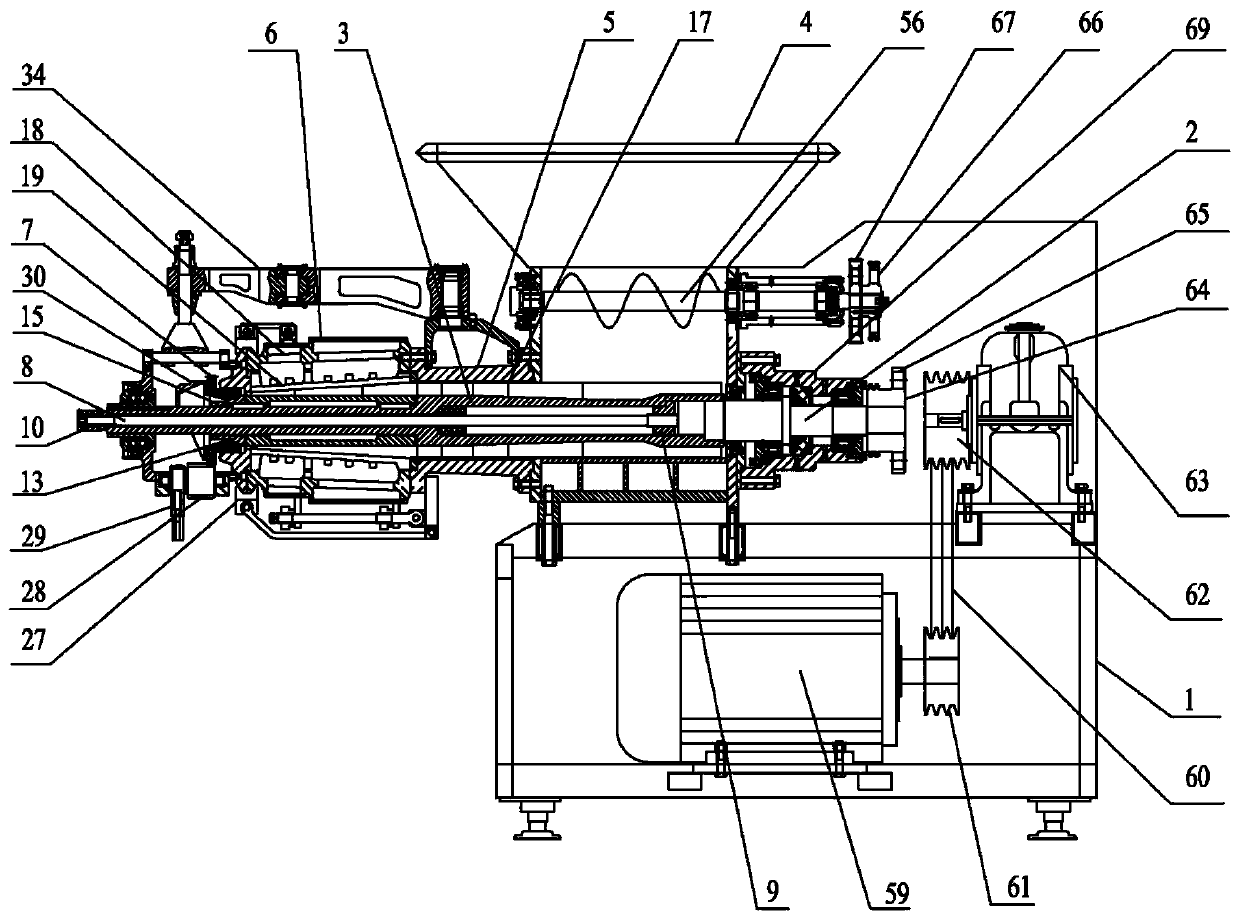

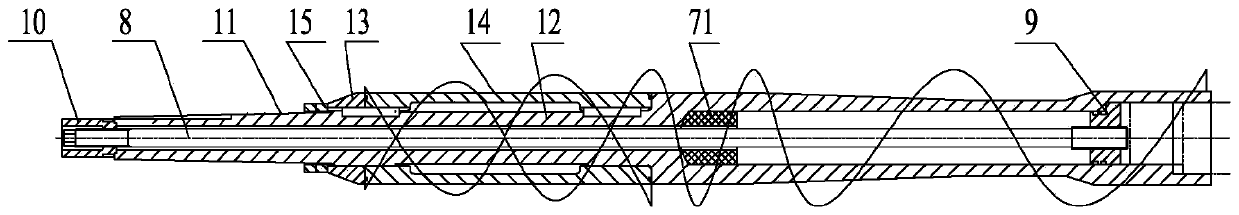

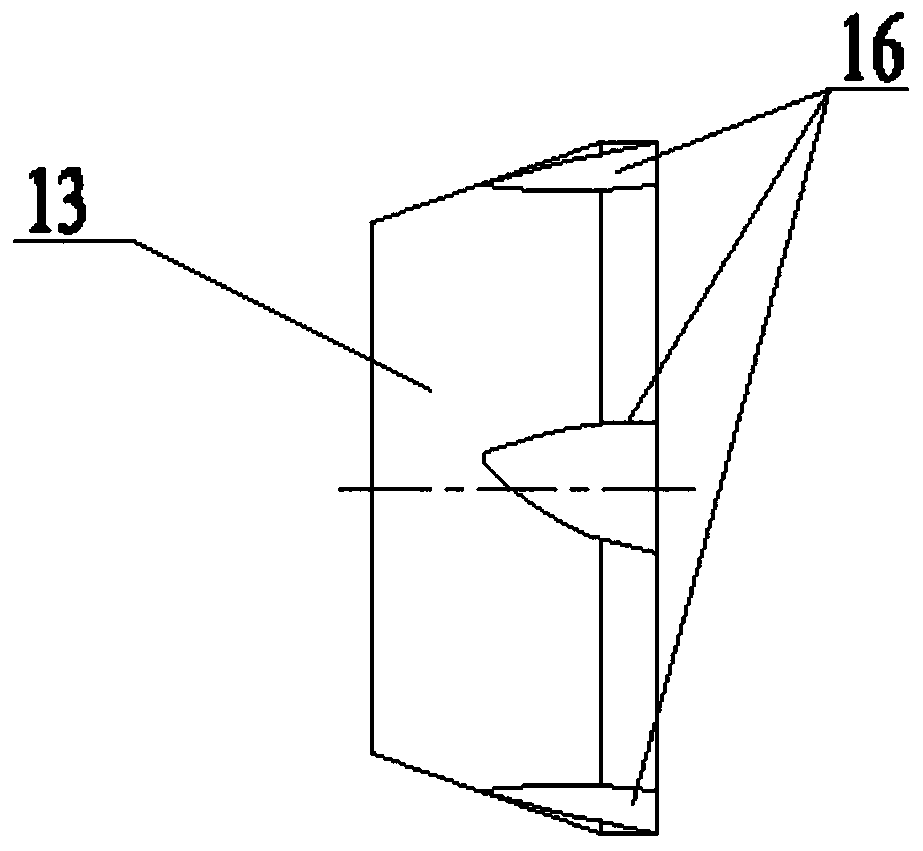

[0050] This embodiment provides a bone and meat separator, such as figure 1 As shown, it includes a frame 1, a drive mechanism, a transmission shaft 2, a screw shaft 3, a feed hopper 4, a pressurization part 5 and a flesh and bone separation part 6, and the feed hopper 4 is arranged on the frame 1, and the feed hopper 4 The outlet is communicated with the inlet of the supercharging part 5, the outlet of the supercharging part 5 is connected with the inlet of the bone-meat separation part 6, one end of the transmission shaft 2 is connected with the output end of the driving mechanism, and one end of the screw shaft 3 is sleeved on the other end of the transmission shaft 1 and can be opposite to each other. As the transmission shaft 2 moves, one end of the screw shaft 3 in this embodiment is provided with an inner triangular hole, and the end connecting the transmission shaft 2 and the screw shaft 3 is set as an outer triangle matching the inner triangular hole; Below the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com